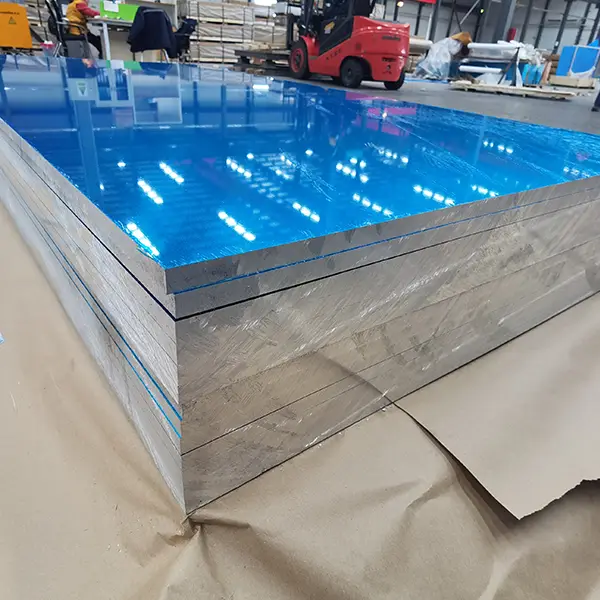

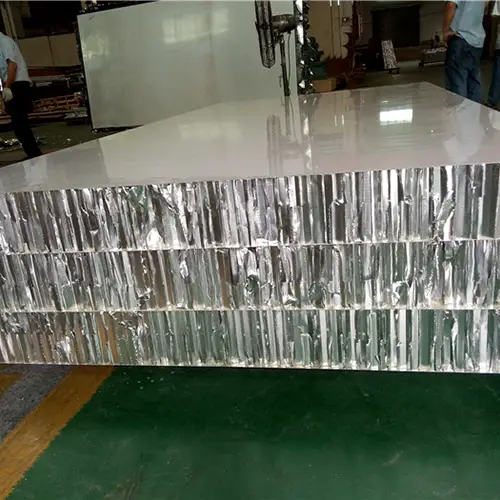

Marine Grade Aluminum Sheet

The marine field is an emerging industry for aluminum alloy applications, and marine grade aluminum plates are becoming more and more popular. As a large supplier of marine grade aluminum sheets, Yongsheng Aluminum has a wealth of marine grade aluminum for sale, such as 5052, 5083, 6061, 5086, 6063, etc. YSA Marine Aluminum Plate is corrosion-resistant and you can use it to build the sides and bottom of ships in saltwater environments. We will provide you with the best price!

Alloy: 5052, 5083, 5086, 5454, 6063, etc

Temper: H12, H14, H18, T6, T651, T351, etc

Thickness: 0.2-170mm

Width: 800-2500mm

Sample: Free & A4 Size

Performance Standards for Marine Aluminum Plate

- High specific strength and specific modulus: The structural strength and size of the ship are closely related to the yield strength and elastic modulus of the material. Since the elastic modulus and density of aluminum plates are basically the same, the addition of alloy elements has little effect, so increasing the yield strength within a certain range is beneficial to lightening the ship structure.

- Excellent welding performance: Good weldability can make the aluminum plate less prone to cracks formed during the welding process, that is, the aluminum plate should have good welding crack resistance, because the lost welding performance cannot be restored through reheat treatment under shipbuilding conditions.

- Good corrosion resistance: Ship structures need to be used in harsh seawater media and marine environments, so corrosion resistance is one of the main signs of marine aluminum plates.

- Have good cold and hot forming properties: Since ship manufacturing requires cold and hot processing, marine aluminum plates must be easy to process, have no crack defects, and still meet strength and corrosion resistance requirements after processing.

Specifications

Marine Aluminum Sheet Specifications | |

Alloy |

|

Temper | H12, H13, H16, H18, H111, H112, H116, etc |

Size | 4×8 Aluminum Sheet、4×10 Aluminum Sheet、5×10 Aluminum Sheet |

Thickness | 2mm, 3mm, 2.5mm, 3.5mm, 4mm, 5mm, 6mm, 10mm, etc |

Width | 800-2500mm |

Surface Treatment | Anodized, coated, mirror marine aluminum sheet, etc |

Marine Grade Aluminium Alloy

YSA marine grade aluminum plates enjoy a good reputation among customers. We can provide you with 5000 series and 6000 series marine aluminum alloys, such as 5052, 5083, 6061, 6063, etc.

5052 aluminum is a non-heat treatable alloy with excellent fatigue resistance. Marine 5052 aluminum alloy mainly includes 5052 H32 aluminum plate and 5052 H34 aluminum plate, which has good processing performance and corrosion resistance.

5083 aluminum plate has moderate strength, excellent corrosion resistance, good weldability, and can be cold processed. It is a typical marine grade aluminum plate. 5083 H321 aluminum plate and 5083 H116 aluminum plate are very suitable for high corrosion resistance applications in harsh marine environments. It is mostly used in shipbuilding decks, engine pedestals, ship sides, bottom outer plates and other parts.

Silicon is added to 6061 aluminum alloy to ensure its corrosion resistance, and it is easier to precision process and weld than 5052 aluminum. In the field of marine ships, 6061 T4, 6061 T6, and 6061 T651 are the most commonly used states.

6063 alloy aluminum plates can be processed into various profiles. After heat treatment and strengthening, they can obtain good mechanical properties, physical properties and corrosion resistance, and are suitable for use as structural materials for offshore ship containers. In addition, the 6063 aluminum alloy has good tensile strength and can resist external pressure, reducing the deformation of the container itself.

YSA Marine Grade Aluminum Sheet Advantages

Aluminum alloy has the characteristics of small specific gravity and elastic modulus, corrosion resistance, weldability, easy processing, non-magnetic and good low temperature performance. When used in ships, it has the following advantages:

- Due to its small specific gravity, it can reduce the weight of the ship, reduce the capacity of the single engine, and increase the speed; it can reduce fuel consumption and save fuel; it can improve the aspect ratio of the ship, increase its stability, and make the ship easier to maneuver; it can also increase the Load up the weight and get extra profit.

- Due to its good corrosion resistance, it can reduce maintenance costs such as oiling and extend its service life (usually more than 20 years).

- It has good processing and forming performance, and is easy to carry out various forms of processing such as cutting, stamping, cold bending, forming and cutting, etc., and is suitable for streamlining the hull; it can extrude large wide thin-walled profiles, reduce the number of welds and make the hull structure Rationalization and lightweighting.

- It has good welding performance and can be welded easily.

- The elastic modulus is small, the ability to absorb impact stress is large, and it has greater safety.

- Aluminum scrap is easily recovered and can be recycled.

- It has no low-temperature brittleness and is most suitable for low-temperature equipment.

- Since it is non-magnetic, the compass is not affected; the all-aluminum boat can avoid mine attacks and is suitable for use as a minesweeper.

- There is no insect damage or deformation caused by drying; it does not burn and is safer in case of fire.

Marine Aluminum Sheet Plate Applications

Aluminum Plate for Ship Deck

The ship deck refers to the large plate frame above the inner bottom plate that covers the inner space of the ship or divides it into layers. Mainly composed of aluminum plate and stock price. The deck is divided into upper and lower parts: the upper deck is the uppermost continuous deck from bow to stern; the lower deck is the deck at the upper bottom of the ship. The space between the upper deck and the lower deck is called the interdeck compartment, and the space between the lower deck and the bottom of the ship is called the cabin.

The main alloys of aluminum plates for decks are: 5052, 5083, 5086 and 6061, and most of them use aluminum diamond plates. The main specifications are as follows:

Alloy | Temper | Thickness (mm) | Width (mm) | Length (mm) |

5052 | F, O, H12, H14, H16, H18, H32, H112, etc | 3-50mm | 20-2650mm | 500-16000mm |

5083 | O, H12, H14, H16, H28, H32, H112, H116, etc | 3-50mm | 20-2600mm | |

5086 | O, H111, H112, H116, H321, etc | 3-50mm | ≤3600 | |

6061 | T4, T6, T651, etc | 3-50mm | 500-2800mm |

Aluminium Plate for Yachts Building

The manufacturing of aluminum alloy yachts mainly uses 5052 and 5083 aluminum plates. Marine grade 5083 aluminum plate has high hardness and is not easy to bend and form, but has excellent corrosion resistance. Almost all yachts at sea are made of 5083 H116 and 5083 H321. Small yachts in fresh water generally use 5052 H32 aluminum plates and 5052 O aluminum plates. Some shipyards will use 5083 for the underwater part of the ship and 5052 for the above-water part of the ship.

Alloy | Temper | Thickness (mm) | Width (mm) | Length (mm) |

5052 | F, O, H12, H14, H16, H18, H32, H112, H114, etc | 3-50mm | 20-2650mm | 500-16000mm |

5083 | O, H12, H14, H16, H24, H28, H32, H112, H116, etc | 3-50mm | 20-2600mm |

Aluminum Plate for Fishing Boat

Aluminum alloy fishing boats have strong adaptability, light hull, and are easy to transport and carry. Accessories can also be selected according to the user’s requirements. The service life is 10 times longer than that of fiberglass. Even if it cannot be used in the end, it can still be recycled. Aluminum plates for fishing boats mainly include 5052, 5083, 6061, 6063, etc. For small hulls, 5052 H32, 5052 H34, and 6061 T6 are often chosen as raw materials. Hull alloy 5086 H32 is the most popular. The general thickness is between 0.45-12.7mm. It is more expensive than 5052, but it is stronger than 5052. Structural components such as the frame and gunwales of the hull are mostly made of aluminum profiles such as 6061 and 6063.

Alloy | Temper | Thickness (mm) | Width (mm) | Length (mm) |

5052 | F, O, H12, H16, H24, H28, H112, H114, etc | 3-50mm | 20-2650mm | Any |

5086 | O, H111, H112, H116, H321, etc | 3-50mm | ≤3600 | |

6061 | T4, T6, T651, etc | 3-50mm | 500-2800mm | |

6063 | T5, T6, etc | 3-50mm | ≤700mm |

Aluminum Plate for Ship Chimney

Ship chimneys are mainly used to reduce the harmful effects of exhaust gas on ships. The exhaust pipe usually extends above the deck superstructure and the highest deck. The main aluminum plate alloys used in ship chimneys are 5052, 5A03 and 5083. Its main specifications are as follows:

Alloy | Temper | Thickness (mm) | Width (mm) | Length (mm) |

5052 | F, O, H12, H16, H24, H28, H112, H114, etc | 3-50mm | 20-2650mm | Any |

5083 | O, H18, H24, H32, H111, H112, H116, H321, etc | 3-50mm | 20-2600mm |

Marine Aluminum Plate Deep Processing Products

Marine Grade Aluminum Checker Plate

The surface of aluminum tread plate has various convex shapes such as diamond, square, circle, pebble, lentil shape, etc. These aluminum checker plates are often used in ship decks, stairs, and mechanical equipment. While ensuring their corrosion resistance, they also show good decorative effects and anti-slip properties.

Marine Grade Aluminum Foam Plate

Marine foam aluminum sheets are composed of a combination of evenly distributed skeletons and micropores. They have a three-dimensional network structure and are a type of porous metal. It has the functions of sound absorption, heat insulation, sound insulation, electromagnetic shielding, shock absorption and buffering. It also has the inherent fireproof, moisture-proof, non-toxic, odorless, corrosion-resistant properties of metal aluminum. Commonly used for cabin sound insulation.

Marine Grade Aluminum Honeycomb Panel

The panels on both sides of the aluminum honeycomb panel are high-strength aluminum plates, and the inner layer is a special hexagonal aluminum honeycomb. It can be processed into various thicknesses and is often used in ship decks, gangways and other parts. The use of this material can reduce the weight of trains and ship hulls, greatly improve the navigation speed and load capacity of vehicles and ships, and play a role in saving energy and reducing pollution.

Aluminum Ribbed Plate for Ships

Aluminum ribbed plate mainly act on the hull structure and key parts to strengthen and support.

Marine Grade Aluminium Sheet Surface Treatment

There are two commonly used surface treatment methods for marine aluminum plates: anodizing and color coating. Both can effectively improve the corrosion resistance of aluminum, extend its service life, reduce maintenance costs, and enhance the aesthetics of the hull.

Anodizing: By thickening the oxide film on the surface of the aluminum plate, a hard coating is obtained to improve corrosion resistance. Marine 5000 series and 6000 series are best suited for anodizing.

Color coating: Color coating can enhance the adhesion between aluminum plate and paint. To further reduce the contact between aluminum and the external environment, commonly used ship coatings include polyurethane coatings, epoxy coatings, etc.