Aluminum Mirror Sheet

Aluminum Sheet Mirror Introduction

Mirror aluminum sheet refers to the treatment by rolling, polishing and other methods, so that the surface of the sheet shows a mirror effect. At present, the commonly used aluminum mirror sheet is generally 1xxx, 3xxx, 5xxx series, which can meet the general decoration and other fields.YSA produces mirror aluminum reflectivity up to 86% and above, the reflectivity of high-end aluminum sheet mirror is generally above 90%.

Mirror aluminum sheets can generally be divided into:

Surface Polished Finish | 800 Standard Polished |

850 High Polished | |

890 Ultra High Polished | |

Surface Treatment | 800 Series Oxidized Polished Aluminum Sheets |

R Series Unoxidized Polished Aluminum Sheets |

3 Main Steps of Mirror Aluminum Manufacturing

1. Generally, the mirror aluminum sheet is made by rolling the alloy aluminum plate through the mirror roller, so that the surface of the alloy aluminum plate or aluminum alloy plate has the effect of mirror glass. The precision of the rolling machine determines the reflectivity of the mirror aluminum plate.

2. Rolling is to better flatten the plate to the plate, stretch the raw material, and change the thickness and length of the plate.

3. Grinding and polishing is to change the original uneven areas on the plate to make it smoother without damaging the original characteristics of the product.

Why Choose Us

Henan Yongsheng uses rolling technology to produce mirror aluminum sheets/coils and has 25 years of production experience. Our factory specializes in the production of color-coated and anodized mirror aluminum. The polished surface is smooth and even, smooth and bubble-free, and there are no defects such as cracks and scratches. We has the following advantages:

1. Shape + thickness + surface treatment can be customized;

2. Economical and affordable.

3. The oxide film layer has no traces of corrosion or blistering; the thickness of the oxide film is not less than 0.15mm (dry oxidation).

4. The coating is uniform, the color is consistent, the color is bright and beautiful, and there are no defects such as pores and pinholes.

5. The adhesion of the coating complies with the GB/T 1769-1998 standard.

6. The reflectivity of hot-rolled mirror aluminum is about 10% higher than that of polished mirror aluminum.

YSA Mirror Aluminum Detailed Parameters

Depending on the surface treatment, mirror aluminum plates can be divided into embossed mirror aluminum, mirror aluminum tread plates, color mirror aluminum, and anodized mirror aluminum.

YSA mirror aluminum adopts two processes: casting and hot rolling. Cast-rolled mirror aluminum plate is low in price, high in strength, and has a certain cost performance; hot-rolled mirror aluminum plate is slightly more expensive, has good elongation and bending properties, and can be subsequently anodized.

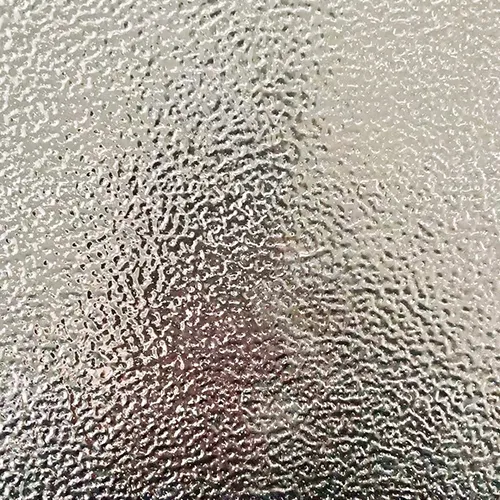

Embossed Aluminum Mirror Sheet

Mirror embossed aluminum is also known as mirror aluminum stucco/tread plate. It uses mirror aluminum as the base material and is machined by embossing rollers. This material combines the advantages of aluminum mirror sheets and embossed aluminum sheets. The patterns include orange peel, diamond, pebble and lentil patterns, etc., showing astigmatism effect. Reflectivity ≥85%. Embossed Aluminum Mirror Sheet can be used in refrigerators, air conditioners, freezers, etc.

Grade | 1060, 1100, 3003, 3005, 5052, 5005, etc |

Temper | O-H112, etc |

Thickness | 0.1-10mm |

Width | 100-3000mm |

Length | Any |

Process | Cold Rolling and Hot Rolling |

MOQ | 1 Ton |

Delivery Time | 7-25 Days After Order Confirmation |

Payment terms | L/C,D/A,D/P,T/T , West Union, Money Gram, Etc. |

Standards | ASTM-B209,EN573-1,GB/T3880.1-2006 |

Certificate | ISO, RoHS |

Yongsheng Aluminum can supply orange peel embossed mirror aluminum sheets, spherical embossed mirror aluminum sheets, pebble aluminum mirror sheets, etc. The size and color can be customized. Details are as follows:

Qrange Peel Embossed Mirror Aluminum

Spherical Embossed Mirror Aluminum

Pebble Aluminum Mirror Sheet

Mirror Aluminum Tread Plate

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Mirror Aluminum Diamond Plate

Mirror 5 Bars Aluminum Tread Plate

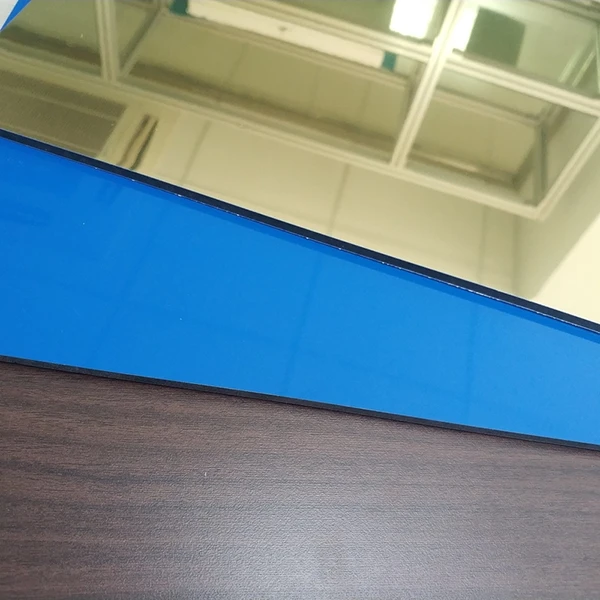

Color Aluminum Sheet Mirror

Colored mirror aluminum uses a physical friction polishing process to give the surface of the aluminum sheet a reflectivity of about 82%, and then paint is applied to the surface of the aluminum plate. YSA color-coated mirror aluminum sheet has high reflectivity, easy processing, various colors, good formability, durability and easy cleaning. It widely used in lighting, decoration, signs, cosmetic boxes, etc.

We can supply basic and metallic colors:

Basic colors: Chinese red mirror aluminum, orange mirror aluminum, gold mirror aluminum, green mirror aluminum, blue mirror aluminum, purple mirror aluminum, black mirror aluminum.

Metal color: titanium mirror aluminum, red copper mirror aluminum, rose gold mirror aluminum, light bronze mirror aluminum.

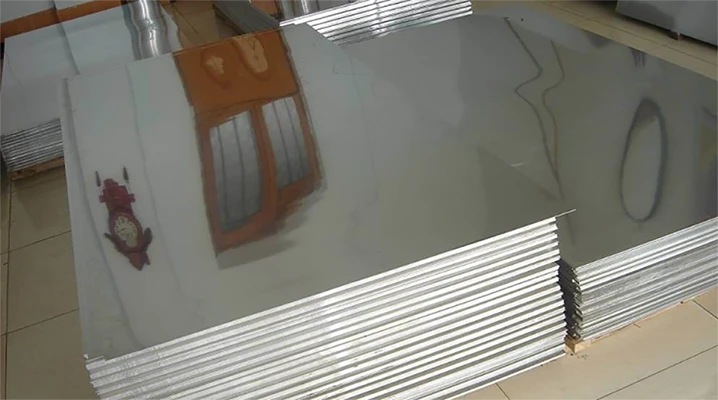

Anodized Mirror Finish Aluminum Sheet

Anodized mirror aluminum sheet refers to the surface of the aluminum sheet being anodized to produce an aluminum oxide film. The surface reflectivity of anodized mirror aluminum can reach 86% and above. YSA can produce anodized mirror aluminum plates in various colors to ensure a clean and paint-free surface, high hardness, scratch resistance, and corrosion resistance. It can be used for lighting reflective panels and indoors. Building materials, electrical panels, electronic product casings, automobile decoration and other fields

Common Alloys Used for Mirror Aluminum

The commonly used aluminum alloys for mirror aluminum sheet are 1000 series, 3000 series and 5000 series.

1000 series mirror aluminum sheet/coil

The 1000 series aluminum is a commonly used alloy system for mirror aluminum sheets. Its production process is simple and the price is cheap. The 1xxx series of 1050, 1070, and 1060 aluminum sheets are commonly used alloys for the production of mirror aluminum sheets.

1050, 1060, 1100 mirror aluminum sheet/coil

Thickness: 0.1-3.5mm

Width: 10-1700mm

Length: 500-16000mm

Reflectivity: 80%, 86%, 95%

Tempers: O/H12/H14/H16/H18/H24

Applications: Architectural decoration, lighting fixtures, solar reflection equipment, electronic product casings.

3000 series mirror aluminum sheet/coil

The commonly used 3000 series alloys for mirror aluminum sheets include 3003, 3004, 3104, and 3105. The 3xxx series aluminum alloys have higher strength and better bending properties than the 1xxx series.

3003, 3105 mirror aluminum sheet/coil

3003 is the most commonly used alloy product among the 3000 series aluminum and has excellent anti-rust properties. The aluminum content in 3105 mirror aluminum can reach 99.8%, and the 3000 aluminum-manganese alloy series mirror aluminum produced by YSA has a reflectivity of more than 86%.

Thickness: 0.15-10mm

Width: 10-1700mm

Length: 500-16000mm

Tempers: O, H12, H14, H18, H19, etc

Total reflectance: 80%, 86%, 95%

5000 series mirror aluminum sheet

5454, 5182, 5183, and 5754 are commonly used mirror aluminum sheet alloys for 5xxx series aluminum. It has high tensile strength and is widely used in pressure vessels, marine facilities, tanks, etc. Its detailed specifications are as follows:

Thickness: 2-8mm

Width: 1200-2600mm

Length: Any

Temper: O, H22, H32, H111, H112

Total reflectance: 80%, 86%, 95%