5182 Aluminum Coil

5182 aluminum alloy is an Al-Mg alloy that is widely used and is the most promising alloy. It has good corrosion resistance, excellent weldability, good cold workability, and medium strength. Yongsheng Aluminum strictly selects materials, has mature technology, and strictly controls the production process. 5182 aluminum sheets, 5182 aluminum coils, 5182 aluminum strips, etc. have stable sales, large supply volume, and global distribution, and have received praise from many parties.

Product Introduction

5182 aluminum coil is a metal product produced by rolling and bending processing in a casting and rolling mill. Due to the addition of elements such as magnesium and chromium, 5182 aluminum coils have high strength, with a tensile strength of over 175MPa. They perform well in structural applications and are common in the automotive field; unlike the 5000 series of 5454 aluminum coils, 5454 Due to the addition of manganese, it has great applications in the field of shipbuilding.

Product Parameters

| Aluminum Alloy | 5182 Aluminum Coil |

| Thickness (mm) | 0.2-8.0 |

| Width (mm) | 8-2600 |

| Temper | O,H12,H14,H34,H32,H36,H111,H112, etc |

| Material Process | CC AND DC |

| Customerize Size | Size can be produced as per clients requirement |

| Surface | Mill finish ,Color coated(PVDF& PE),Stucco Embossed ,Bright Polish,Anodizing |

| Mirror,Brush,Perforated,Tread plate ,Corrugated etc | |

| Quality Standard | ASTM B209,EN573-1 |

| MOQ Per Size | 1 Ton (According to Specifications) |

| Payment Terms | TT OR LC at sight |

| Delivery Time | Within 25 days after receipt the lc or deposit |

| Material Quality | Tension levelled ,Flat ,Free of defects like oil stain,Roll Marks,Waves,Dents |

| scratches etc ,A+++ quality, production process passed SGS. | |

| Packing | Standard export worthy wooden pallets |

| and standard packing is about 2 tons/pallet | |

| Pallet weight also can be as per client’s requirement |

Product Properties

Chemical Composition

|

Element |

Present(%) |

|

Al |

Remain |

| Zn |

≤0.25 |

|

Fe |

0-0.35 |

| Cu |

0.15 |

|

Mg |

4.0-5.0 |

| Mn |

0.2-0.5 |

|

Si |

≤0.20 |

| Others |

0.05 |

Mechanical Properties

|

Tensile Strength |

Yield Strength | Elongation |

| 275-365MPa | 180-240MPa |

12-18% |

Product Applications

5182 aluminum coil has medium strength, high tensile strength and yield, and excellent weldability. It can be widely used in many parts and components such as tank truck materials, cans, automobile body panels, operating panels, brackets, etc. The most commonly used tempers of 5182 are H19 and H111.

Among them, 5182 aluminum alloy can lid pull ring material is used to manufacture lids and pull rings of all-aluminum cans and tinplate cans. The can body is made of 3104 H19 aluminum strip with a thickness of 0.25mm~0.29mm; the lid is made of 5182 H19 aluminum coil strip with a thickness of about 0.27 mm; and the pull ring and sealing sheet materials are mostly made of 5182 H19 aluminum strip. . In addition to being used for all-aluminum cans, 5182 aluminum alloy can lid materials are also widely used in the lids of tinplate cans and other packaging containers. Tank truck materials commonly use 5182 H111 aluminum coils.

Product Advantages

- High hardness, smooth surface, suitable for processing.

- The thickness is uniform and flat, ensuring a thickness tolerance of ±0.005mm.

- Light weight, heat resistant, acid and alkali corrosion resistant.

- Odorless, non-toxic, good printing effect.

- Recyclable, economical and environmentally friendly.

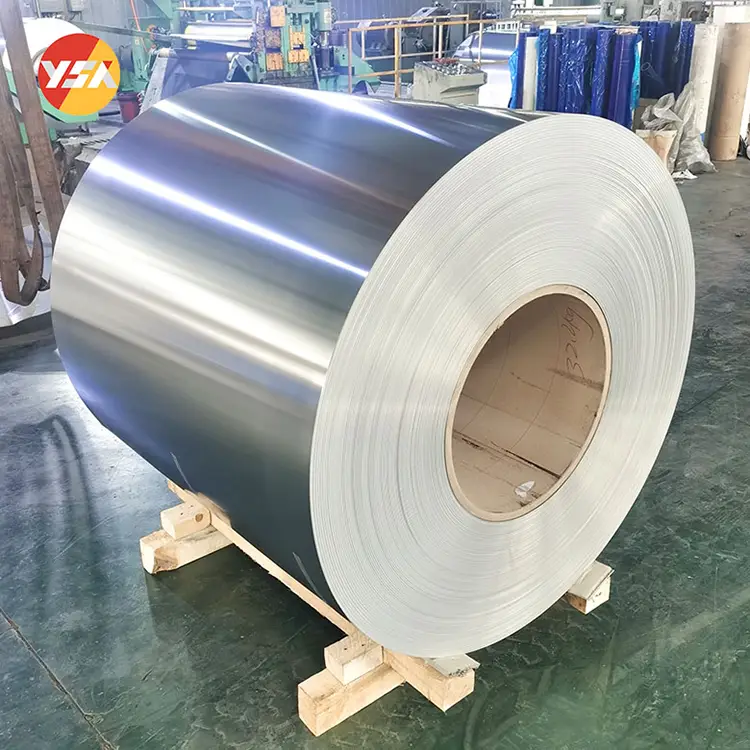

Product & Packaging Photos

Why Choose Us

Yongsheng Aluminum is a leading aluminum products manufacturer&supplier in China with 25 years of export experience. Our outstanding product quality, price, and always on-time delivery has won us many long term partners and gained a great reputation worldwide. We provide one-stop product solution for both CC&DC aluminum products.

Contact us to get your quotation.

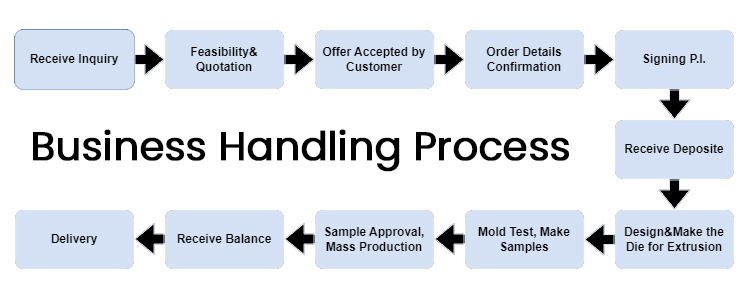

Business Handling Processes