Aluminum Circle For Pressure Cooker

Aluminum circles for pressure cookers serve as the base of the cooker, made from high-quality aluminum alloys such as 3003/3004 aluminum circles. They provide a smooth and stable surface for efficient heat distribution. The surface is typically clean and may have a non-stick coating. The dimensions vary based on the cooker’s size, and they adhere to safety standards. Follow manufacturer instructions for maintenance.

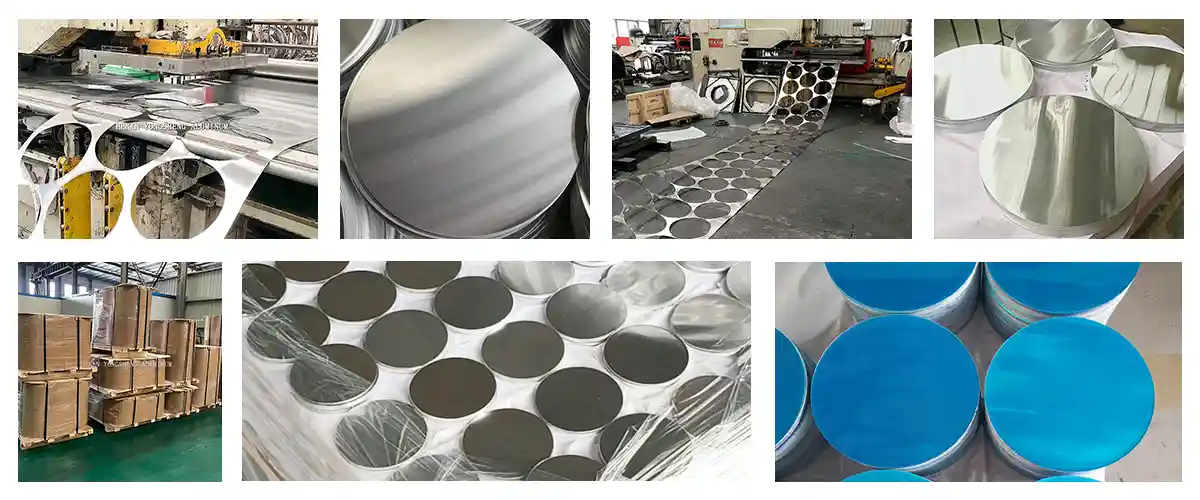

Yongsheng Aluminum factory covers 780,000 square meters has 27 production lines, 32 punch presses, 10 CNC lathes etc. We focus on aluminum sheet/coil, aluminum foil, aluminum strip, aluminum circle, color-coated aluminum, embossed aluminum, aluminum checker sheet, mirror aluminum sheet etc. The annual output reaches 300,000 tons and continuing expanding.

Product Introduction

The 3000 series aluminum circle is a commonly used alloy for pressure cookers due to its excellent characteristics including strength, formability, corrosion resistance and weldability. The 3000 series aluminum alloys are a group of wrought aluminum alloys primarily composed of aluminum (Al) and manganese (Mn). The most common alloy in this series is 3003, which is widely used in various applications, including pressure cookers.

Specifications

| Alloy | 3003/3004/3104/5052 |

| Temper | H18/H19 |

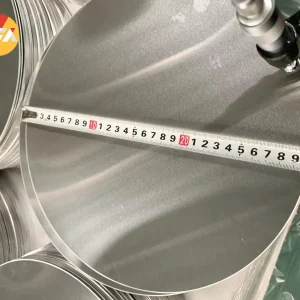

| Diameter | 18 centimeters (7 inches) for smaller cookers to 30 centimeters (12 inches) or more for larger cookers |

| Thickness | 2.0 to 4.0 millimeters (0.08 to 0.16 inches) |

| Size | Size can be customized |

| Delivery Time | Ready stock 7-10 days |

| MOQ | 1 ton |

| Loading Port | Qingdao Port, Tianjin Port, Shanghai port. |

| Price Terms | FOB, CIF, CFR, CNF, etc. |

| Quality Control | Mill Test Certification is supplied with shipment, Third Part Inspection is acceptable. |

Aluminum Circle For Pressure Cooker

While the 1 series aluminum alloys, such as 1100, also have their advantages, such as high electrical conductivity and good corrosion resistance, the 3 series alloys provide a better balance of properties specifically suited for pressure cooker applications, including strength, formability, corrosion resistance, weldability, and cost-effectiveness.

Due to its properties and characteristics, 3 series aluminum is preferred for making pressure cookers

- Strength and Formability: The 3 series aluminum alloys, such as 3003, offer better strength and formability compared to the 1 series alloys. The enhanced strength ensures durability and structural integrity of the pressure cooker, while improved formability allows for complex shapes and designs.

- Corrosion Resistance: The 3 series aluminum alloys exhibit better corrosion resistance than the 1 series alloys. Pressure cookers often come into contact with moisture and acidic food ingredients, and the corrosion resistance of the 3 series helps maintain the cooker’s longevity and safety.

- Weldability: The 3 series aluminum alloys have improved weldability compared to the 1 series. Welding is a crucial process in pressure cooker manufacturing, and the better weldability of the 3 series aluminum simplifies the fabrication process and ensures strong and reliable joints.

- Cost Considerations: The 3 series aluminum alloys, such as 3003, are generally more cost-effective than the 1 series alloys. This makes them a practical choice for mass production of pressure cookers without compromising on quality and performance.

Product Advantages

Aluminum Pressure Cookers Using 3000 Series Aluminum Offers:

- Excellent Formability: The 3000 series aluminum, including alloy 3003, offers excellent formability, allowing it to be easily shaped and formed into the desired pressure cooker components. This enables manufacturers to create intricate designs and structures.

- Heat Conductivity: Aluminum in the 3000 series has good thermal conductivity, facilitating efficient heat distribution and transfer during the cooking process. This helps in achieving uniform cooking results and reducing cooking time.

- Corrosion Resistance: Alloy 3003 exhibits good resistance to corrosion, making it suitable for use in humid and high-temperature environments, such as pressure cookers. It helps prevent the formation of rust or corrosion that could affect the cooker’s performance or contaminate the food.

- Lightweight: The 3000 series aluminum is lightweight, contributing to the overall weight reduction of the pressure cooker. This makes it easier to handle and maneuver while cooking.

- Food Safety: Aluminum in the 3000 series is considered food-safe and does not react with acidic or alkaline ingredients commonly used in cooking. It ensures that the food cooked in the pressure cooker remains safe for consumption.

- Cost-Effective: The 3000 series aluminum alloys, including 3003, are cost-effective compared to some other aluminum alloys, making them an economical choice for pressure cooker manufacturers.

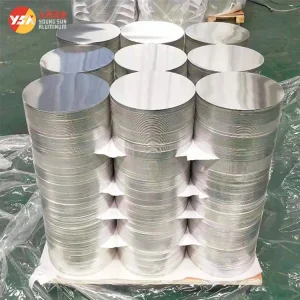

Product & Packaging Photos

Why Choose Us

Yongsheng Aluminum is a leading aluminum products manufacturer&supplier in China with 25 years of export experience. Our outstanding product quality, price, and always on-time delivery has won us many long term partners and gained a great reputation worldwide. We provide one-stop product solution for both CC&DC aluminum products.

Contact us to get your quotation.

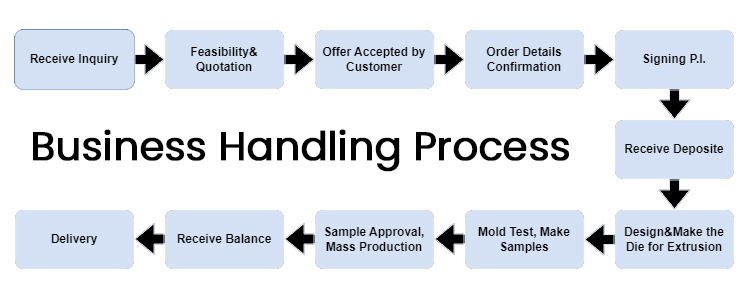

Business Handling Processes