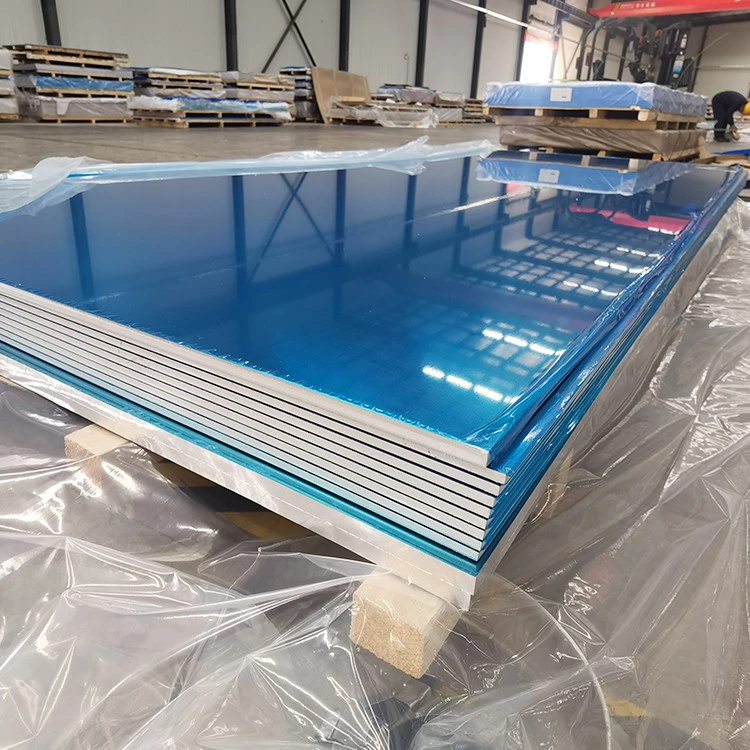

Product Introduction

Architectural cladding using anodized aluminum is a popular choice in the construction industry. Anodizing is an electrochemical process that enhances the natural oxide layer on the surface of aluminum, resulting in a durable and attractive finish.

Architectural cladding using anodized aluminum offers numerous benefits. It provides versatility in terms of colors and finishes, while being highly durable and resistant to corrosion. Anodized aluminum cladding is weather-resistant, lightweight, and structurally sound. It requires minimal maintenance and is environmentally friendly.

Specifications

| Alloy | 1000, 3000, 5000, 6000, 8000 Series |

| Temper | O – H112 , T3 – T8 , T351 – T851 |

| Width | up to 2600 mm |

| Thickness | 0.01 mm-350 mm |

| Size | Size can be customized |

| Delivery Time | Ready stock 7-10 days |

| MOQ | 1 ton |

| Loading Port | Qingdao Port, Tianjin Port, Shanghai port. |

| Price Terms | FOB, CIF, CFR, CNF, etc. |

| Quality Control | Mill Test Certification is supplied with shipment, Third Party Inspection is acceptable. |

Applications

Architectural cladding using anodized aluminum is suitable for a wide range of buidings, including commercial, residential, educational, healthcare, cultural, recreational, transportation, and industrial facilities. Its versatility, durability, and aesthetic appeal make it a popular choice for enhancing the exterior appearance and performance of buildings across various sectors.

Product Advantages

As a professional manufacturer with decades of experience in aluminum materials, our anodized aluminum exhibits outstanding performance:

- Corrosion Resistance: Yongsheng anodized aluminum features an excellent resistance to corrosion. The oxide layer is highly resistant to fading or degradation, allowing it to maintain surface integrity and durability even in harsh environments, addressing the shortcomings of regular aluminum in acidic or alkaline conditions.

- Insulation: Our anodized aluminum exhibits good insulation properties, making it suitable for electronic and electrical applications as an insulating material.

- Uniformity: The oxide layer of Yongsheng’s anodized aluminum demonstrates high uniformity, ensuring a consistent performance and appearance throughout the entire surface of the aluminum material.

- Controllable Film Thickness: The thickness of the oxide film in anodized aluminum can be precisely controlled by adjusting the processing time and conditions, meeting the requirements of various applications. Yongsheng Aluminum is capable of producing oxide layers with different thicknesses, ranging from a few micrometers to tens of micrometers.

- Adhesion: Yongsheng guarantees excellent adhesion between the oxide layer and the substrate, providing long-lasting protection.

- Thermal Stability: Yongsheng’s anodized aluminum can maintain its performance and appearance stability within a certain temperature range, exhibiting high temperature resistance.

Alloys

Commonly used anodized aluminum materials for architectural cladding is the 1xxxseries aluminum. Specific parameters for the different alloys of the 1xxx aluminum by Yongsheng:

| Alloy | State | Thickness(mm) | Tensile Strength(Mpa) | The Yield Strength(Mpa) | elongation(%) | hardness(HV) |

| 1050 (1060) |

0 | >0.2-0.5 | 60-100 | ≥15 | ≥20 | 20-30 |

| >0.5-1.0 | ≥30 | |||||

| >1.0-4.0 | ≥35 | |||||

| H22 | >0.2-0.5 | 80-120 | ≥60 | ≥12 | 30-40 | |

| >0.5-1.0 | ≥15 | |||||

| >1.0-4.0 | ≥18 | |||||

| H24 | >0.2-0.5 | 95-135 | ≥70 | ≥6 | 35-45 | |

| >0.5-1.0 | ≥8 | |||||

| >1.0-4.0 | ≥10 | |||||

| H26 | >0.2-0.5 | 110-155 | ≥75 | ≥2 | 43-55 | |

| >0.5-1.0 | ≥4 | |||||

| >1.0-4.0 | ≥6 | |||||

| H18 | >0.2-0.5 | ≥125 | ≥85 | ≥2 | 50-65 | |

| >0.5-1.0 | ≥3 | |||||

| >1.0-4.0 | ≥4 | |||||

| Alloy | State | Thickness(mm) | Tensile Strength(Mpa) | The Yield Strength(Mpa) | elongation(%) | hardness(HV) |

| 1100 | 0 | >0.2-0.5 | 75-105 | ≥25 | ≥18 | 25-30 |

| >0.5-1.0 | ≥30 | |||||

| >1.0-4.0 | ≥35 | |||||

| H22 | >0.2-0.5 | 95-130 | ≥75 | ≥12 | 30-40 | |

| >0.5-1.0 | ≥15 | |||||

| >1.0-4.0 | ≥18 | |||||

| H24 | >0.2-0.5 | 110-145 | ≥95 | ≥6 | 38-40 | |

| >0.5-1.0 | ≥8 | |||||

| >1.0-4.0 | ≥10 | |||||

| H26 | >0.2-0.5 | 130-165 | ≥115 | ≥2 | 45-60 | |

| >0.5-1.0 | ≥4 | |||||

| >1.0-4.0 | ≥6 | |||||

| H18 | >0.2-0.5 | ≥150 | ≥130 | ≥2 | 55-70 | |

| >0.5-1.0 | ≥3 | |||||

| >1.0-4.0 | ≥4 | |||||

| 3003 (3A21) |

0 | > 0.2-0.5 | 95-140 | ≥ 35 | ≥ 15 | 30-40 |

| > 0.5-1.0 | ≥ 30 | |||||

| > 1.0-4.0 | ≥ 35 | |||||

| H22 | > 0.2-0.5 | 120-160 | ≥90 | ≥ 12 | 39-53 | |

| > 0.5-1.0 | ≥ 15 | |||||

| > 1.0-4.0 | ≥ 18 | |||||

| H24 | > 0.2-0.5 | 145-195 | ≥125 | ≥ 6 | 42-59 | |

| > 0.5-1.0 | ≥ 8 | |||||

| > 1.0-4.0 | ≥ 10 | |||||

| H26 | > 0.2-0.5 | 170-210 | ≥150 | ≥ 2 | 55-65 | |

| > 0.5-1.0 | ≥ 4 | |||||

| > 1.0-4.0 | ≥ 6 | |||||

| H18 | > 0.2-0.5 | ≥ 190 | ≥ 170 | ≥ 2 | 60-85 | |

| > 0.5-1.0 | ≥ 3 | |||||

| > 1.0-4.0 | ≥ 4 | |||||

| Alloy | State | Thickness(mm) | Tensile Strength(Mpa) | The Yield Strength(Mpa) | elongation(%) | hardness(HV) |

| 3004 (3104) |

0 | > 0.2-0.5 | 155-200 | ≥ 60 | ≥ 13 | 49-62 |

| > 0.5-1.0 | ≥ 16 | |||||

| > 1.0-4.0 | ≥ 20 | |||||

| H22 | > 0.2-0.5 | 190-240 | ≥ 145 | ≥ 10 | 60-84 | |

| > 0.5-1.0 | ≥ 12 | |||||

| > 1.0-4.0 | ≥ 14 | |||||

| H24 | > 0.2-0.5 | 220-265 | ≥ 170 | ≥ 8 | 68-100 | |

| > 0.5-1.0 | ≥ 10 | |||||

| > 1.0-4.0 | ≥ 12 | |||||

| H26 | > 0.2-0.5 | 240-285 | ≥ 190 | ≥ 3 | 72-110 | |

| > 0.5-1.0 | ≥ 4 | |||||

| > 1.0-4.0 | ≥ 6 | |||||

| H18 | > 0.2-0.5 | ≥ 260 | ≥ 230 | ≥ 2 | 85-120 | |

| > 0.5-1.0 | ≥ 2 | |||||

| > 1.0-4.0 | ≥ 3 | |||||

| Alloy | State | Thickness(mm) | Tensile Strength(Mpa) | The Yield Strength(Mpa) | elongation(%) | hardness(HV) |

| 3005 | 0 | >0.2-0.5 | 115-165 | ≥45 | ≥13 | 35-45 |

| >0.5-1.0 | ≥20 | |||||

| >1.0-4.0 | ≥25 | |||||

| H22 | >0.2-0.5 | 145-195 | ≥110 | ≥10 | 40-60 | |

| >0.5-1.0 | ≥15 | |||||

| >1.0-4.0 | ≥15 | |||||

| H24 | >0.2-0.5 | 170-215 | ≥130 | ≥6 | 58-70 | |

| >0.5-1.0 | ≥8 | |||||

| >1.0-4.0 | ≥10 | |||||

| H26 | >0.2-0.5 | 195-240 | ≥160 | ≥3 | 65-83 | |

| >0.5-1.0 | ≥4 | |||||

| >1.0-4.0 | ≥6 | |||||

| H18 | >0.2-0.5 | ≥220 | ≥200 | ≥2 | 80-100 | |

| >0.5-1.0 | ≥3 | |||||

| >1.0-4.0 | ≥3 | |||||

| Alloy | State | Thickness(mm) | Tensile Strength(Mpa) | The Yield Strength(Mpa) | elongation(%) | hardness(HV) |

| 3105 | 0 | >0.2-0.5 | 75-105 | ≥25 | ≥14 | 32-42 |

| >0.5-1.0 | ≥20 | |||||

| >1.0-4.0 | ≥25 | |||||

| H22 | >0.2-0.5 | 95-130 | ≥75 | ≥10 | 39-60 | |

| >0.5-1.0 | ≥12 | |||||

| >1.0-4.0 | ≥12 | |||||

| H24 | >0.2-0.5 | 110-145 | ≥95 | ≥8 | 52-62 | |

| >0.5-1.0 | ≥10 | |||||

| >1.0-4.0 | ≥10 | |||||

| H26 | >0.2-0.5 | 130-165 | ≥115 | ≥3 | 58-72 | |

| >0.5-1.0 | ≥4 | |||||

| >1.0-4.0 | ≥6 | |||||

| H18 | >0.2-0.5 | ≥150 | ≥130 | ≥2 | 65-95 | |

| >0.5-1.0 | ≥2 | |||||

| >1.0-4.0 | ≥3 |