1050 Aluminum

1050 aluminum alloy is one of the most basic and commonly used alloys in aluminum products, whether it is for food packaging, industrial production or simply decorative items, 1050 aluminum is the preferred choice of many manufacturers. So why exactly is 1050 aluminum so popular?

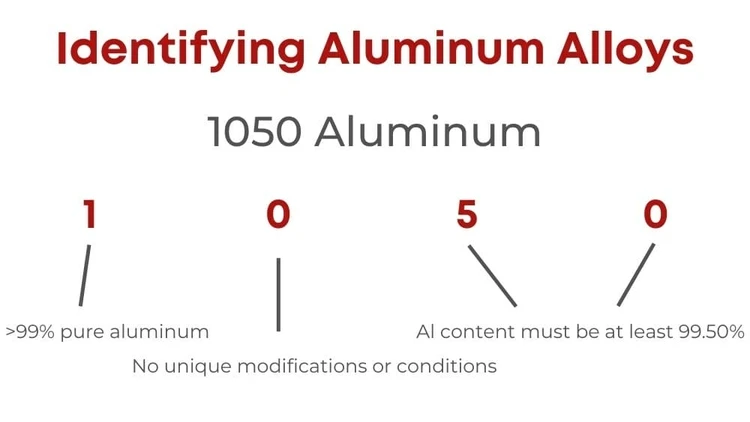

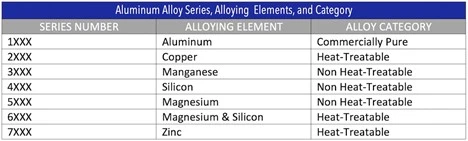

First of all, we have to understand the alloy system, aluminum alloys according to the different elements are divided into one series to eight series, which 1 series contains 1050 aluminum alloy, in addition to 1050 aluminum, there still are 1060, 1070, 1100 and 1235.

1050 Aluminum Alloy

1050 aluminum foil usually refers to the aluminum foil with 99.5% aluminum element content. Since there is no need to add other chemical elements, the production process of 1050 aluminum foil is simple, and the price is cheaper compared with alloy aluminum sheet, which is a kind of aluminum foil with a very wide range of applications.

1060 Aluminum Alloy

1060 pure aluminum foil is widely used in making gaskets, automobile parts, capacitors, food packaging, electronic labels and other industries due to its high plasticity, corrosion resistance, electrical conductivity and thermal conductivity. Yongsheng Aluminum strictly controls the organization, properties, plate type, thickness difference and surface quality requirements of 1060 aluminum foil to ensure the reliable quality of finished products.

1070 Aluminum Alloy

1070 aluminum foil, with high plasticity, corrosion resistance, good electrical and thermal conductivity, is suitable for aluminum foil made into gaskets and capacitors.

1100 Aluminum Alloy

1100 aluminum foil has good formability, corrosion resistance, thermal conductivity and a certain degree of strength, is widely used in the refrigeration industry heat exchanger, chemical and food industry storage containers, the electronics industry, capacitor shell materials.

1235 Aluminum Alloy

1235 aluminum foil has an aluminum content of not less than 99.35%, Yongsheng Aluminum can process 1235 aluminum foil with a thickness of 0.006-0.2mm, which is widely used in cables, adhesive tapes and battery foils because of its excellent rust-resistant properties, formability and solubility.

Other Alloys

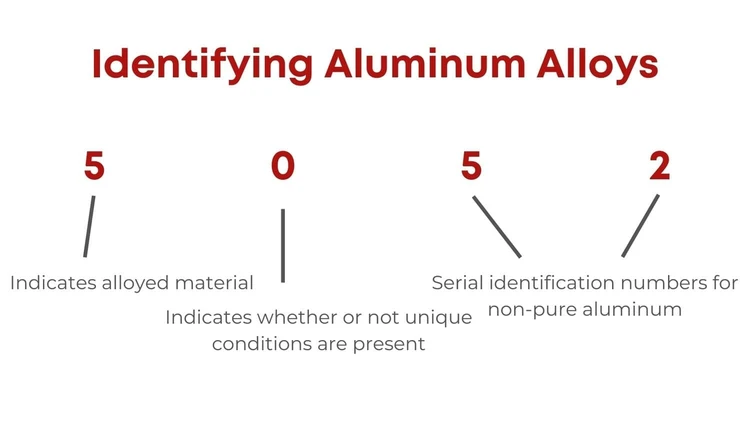

Aluminum alloys of other families. As we said before, aluminum is classified into one to eight families depending on the element.

| Alloy Group | Major Alloying Element | Strength | Ductility | Corrosion Resistance | Weldability | Anodizing |

| 1xxx series | None | Low | High | High | High | High+ |

| 2xxx series | Cu | High+ | Low | Low | Low | Low |

| 3xxx series | Mn | Low+ | High | High | High | High |

| 5xxx series | Mg | Middle | Middle | High | High | High |

| 6xxx series | Si/Mg | Middle | Middle | High | High | High+ |

| 7xxx series | Zn/Mg | High | Low | Middle | Middle | Middle |

3003 Aluminum Alloy

3003 aluminum foil is a commonly used product in the AL-Mn series of alloys. This product has excellent rustproof characteristics, strength is about 10% higher than 1100, good formability, solubility, corrosion resistance. It is used for processing parts and components that require good forming properties, high corrosion resistance and good weldability.

3003 aluminum foil is mainly used in electronic components (electronic foil), honeycomb materials, building materials sound insulation (viaducts, high-speed railroads, etc.), and as a food packaging foil (3003 aluminum foil packaging bags, vacuum aluminum foil bags) and other industries.

3004 Aluminum Alloy

3004 aluminum foil in the application of food packaging, lunch box material aluminum foil container foil in many ways, 3004 aluminum foil high hardness, good load bearing, stamping effect is better than 3003 aluminum foil, can be applied to aluminum foil lunch boxes, product hygiene. As a 3004 aluminum foil manufacturer, Yongsheng Aluminum produces 3004 aluminum foil for containers with good board shape, no black wire, no bright line, no holes and multiple advantages, high quality and low price.

5052 Aluminum Alloy

Yongsheng Aluminum is a raw material manufacturer of 5052 aluminum foil, and the 5052 aluminum foil produced in the factory has stable performance, clean oil removal, few pinholes, good sheet shape, no deformation in cutting, good rust prevention, and other multiple advantages.

The products are widely used in honeycomb material, door panel material, container material and other fields. Executable standards: national standard, American standard, European standard, Russian standard, Japanese standard and so on.

8006 Aluminum Alloy

8006 aluminum foil is a kind of non-heat-treatable reinforced aluminum alloy, Yongsheng Aluminum is a large-scale raw material producer of 8006 aluminum foil, Yongsheng Aluminum can produce 0.006-0.2mm 8006 aluminum foil, the product plate shape is smooth, the surface is clean and free of grease, which is especially suitable for the production of wrinkle-free lunch containers.

8011 Aluminum Alloy

8011-H18 aluminum foil and 8011-O aluminum foil substrate produced by Yongsheng is our advantageous product, Yongsheng Aluminum can process 8011 aluminum foil with thickness of 0.006-0.2mm. This aluminum foil is mainly used in pharmaceutical packaging, food packaging, aluminum foil tape, cable tape, aluminum bottle caps and other fields. Yongsheng Aluminum can be customized and processed according to customers’ needs.

8021 Aluminum Alloy

The thickness of 8021 aluminum foil ranges from 0.006mm-0.2mm, and the width can be controlled from 100-1600mm according to customers’ requirements. 8021 aluminum foil is the main product in food packaging and battery flexible package aluminum foil.

8021 aluminum foil has excellent moisture resistance, light blocking and very high barrier capacity. It is non-toxic and odorless, safe and hygienic. After laminating, printing and gluing, aluminum foil is widely used as packaging material.

In the production process, 8021 aluminum foil has been tested for bacteria, mold and other tests, and the content of heavy metals shall not exceed 0.25 parts per million, which guarantees that the finished products are non-toxic, tasteless, safe and hygienic, so 8021 aluminum foil is often used as pharmaceutical aluminum foil and packaging aluminum foil.

8079 Aluminum Alloy

8079 aluminum foil is the aluminum foil with high strength, good elongation and spreading pressure. The 8079 aluminum foil produced by Yongsheng has multiple advantages such as food grade, clean oil removal, less pinholes, good product plate shape, no deformation in cutting, and so on.

Different alloys have different strengths and weaknesses, and the most suitable alloy is selected based on factors such as mechanical properties, corrosion resistance, formability, and cost-effectiveness.

2 thoughts on “1050 Aluminum”

Awsome info and straight to the point. I don’t know if this is in fact

the best place to ask but do you people have any thoughts

on where to get some professional writers? Thanks 🙂 Najlepsze escape roomy

Contact us by whatsapp: +86 13027629558