Heavy duty aluminum foil typically has a thickness ranging from 0.1 mm to 0.2 mm. This thicker gauge provides increased durability and strength compared to standard household aluminum foil, making it suitable for various industrial and commercial applications. It offers enhanced protection against tearing, puncturing, and other forms of physical damage, making it ideal for applications that require robust and reliable packaging or insulation solutions.

Classification according to the thickness difference

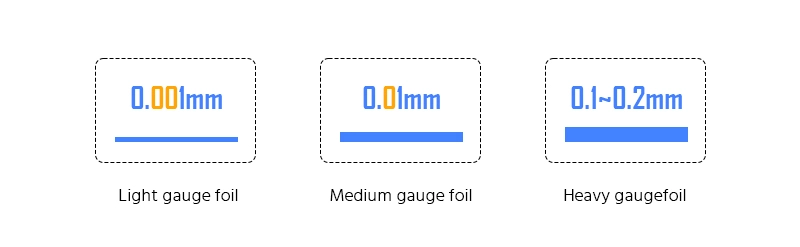

Aluminum foil can be divided into thick foil, single zero foil and double zero foil according to the thickness difference.

| Thick foil (Heavy duty foil) | Foil with a thickness of 0.1 to 0.2 mm |

| Single zero foil (Medium gauge foil) | Foil with a thickness of 0.01mm~0.09mm |

| Double zero foil (Light gauge foil) | 0.001~0.009mm (less than 0.01) |

Applications of Heavy Duty Aluminum Foil

Heavy duty aluminum foil is used in various situations and industries where its thicker and more durable construction is required.

- Industrial insulation

Heavy duty aluminum foil is utilized as a vapor barrier and thermal insulation material in industrial settings. It helps prevent moisture intrusion and provides effective insulation for pipes, ducts, and equipment.

- Food service and catering

Heavy duty aluminum foil is commonly used in commercial kitchens, catering services, and food packaging industries. It is suitable for heavy-duty cooking, grilling, and wrapping of large food items, providing excellent heat retention and protection.

- Transportation and automotive

Heavy duty foil finds applications in the automotive industry for heat shielding, noise reduction, and insulation purposes. It helps protect sensitive components from extreme temperatures and minimizes sound transmission. Roofing and construction: Heavy gauge foil serves as a vapor barrier and insulation material in roofing and construction projects. It helps prevent moisture penetration and enhances thermal efficiency, contributing to energy savings and improved building performance.

- Roofing and construction

Heavy gauge aluminum foil serves as a vapor barrier and insulation material in roofing and construction projects. It helps prevent moisture penetration and enhances thermal efficiency, contributing to energy savings and improved building performance.

Yongsheng Aluminum-Quality Control Methods

Yongsheng Aluminum Industries ensures the thickness consistency of aluminum foil and guarantees its stability and reliability in applications to meet the needs and requirements of customers through the following measures:

Advanced production equipment

Yongsheng Aluminum Industries invests in advanced production equipment, including precision rolling mills and thickness measurement devices. These equipment have high automation and precise control capabilities, enabling accurate rolling and thickness measurement to ensure consistent foil thickness.

Strict process control

Yongsheng Aluminum Industries strictly controls key parameters during the production process, such as rolling speed, rolling force, and number of rolling passes. By precisely controlling these parameters, they ensure that the foil maintains a stable thickness during production and minimizes thickness deviations.

Precise thickness measurement and monitoring systems

Yongsheng Aluminum Industries is equipped with precise thickness measurement and monitoring systems to continuously monitor the foil’s thickness. These systems use advanced sensors and measurement technologies to accurately measure the foil’s thickness with high precision and promptly detect any thickness deviations.

Quality management system

Yongsheng Aluminum Industries has a comprehensive quality management system, including strict quality control and inspection processes. Each batch of aluminum foil undergoes rigorous quality inspection and testing to ensure its thickness meets the specified requirements.

Continuous improvement and technological innovation

Yongsheng Aluminum Industries is committed to continuous improvement and technological innovation, introducing the latest technologies and processes in the production. By constantly improving and optimizing the production processes, they enhance production efficiency and thickness control capabilities.

Through the comprehensive application of these measures, Yongsheng Aluminum Industries can effectively control the thickness consistency of aluminum foil, ensuring its stability and reliability. This enables the aluminum foil produced by Yongsheng Aluminum Industries to meet the needs and requirements of customers and exhibit excellent performance in various applications.