3003 Aluminum Containers

3003 aluminum containers are popular choices for food packaging due to their excellent properties. They can be easily molded into different shapes and sizes to accommodate various food items. The 3003 aluminum foil ensures effective heat retention, keeping food fresh and warm which are widely used in restaurants, catering services, and take-out establishments for packaging and delivering.

Henan Yongsheng Aluminum Co., Ltd. is situated in Gongyi City, Henan Province’s industrial area. Yongsheng is a 25-year-old aluminum foil manufacturer. Production and development of aluminum goods are the main priorities of our factory. With 3200 workers, the factory occupies 780,000 square meters.

3003 Aluminum Containers

3003 aluminum containers are food-grade containers made from the 3003 aluminum alloy. They exhibit excellent strength and corrosion resistance, which is suitable for handling common food items and environmental conditions. Widely used in the food service industry and takeout services, 3003 aluminum foil food containers are ideal for storing hot meals, cold dishes, fried foods, and a variety of other food items. They are a reliable, safe, and environmentally friendly choice, providing convenience and protection for food packaging and preservation.

Product Parameter

|

Alloy |

1xxx Series: 1050, 1060, 1070, 1100, 1235 |

| 3xxx Series: 3003, 3004 | |

| 5xxx Series: 5052 | |

| 8xxx Series: 8011, 8021, 8079 |

| Thickness | 0.03-0.2mm |

| Capacity | ≥100ml |

| Shape | Square, Rectangular, Round, Customizable |

| Size | 200+ Type of Sizes |

| Applications | Cooking, Freezing, Baking and More |

Product Properties

Chemical Composition

| Chemical Element | Present(%) |

| Al | Remain |

| Zn | 0.10 |

| Cu | 0.05-0.20 |

| Mn | 1.0-1.5 |

| Fe | 0.70 |

| Ti | – |

| Cr | – |

| Mg | – |

| Si | 0.6 |

| Other | 0.15 |

Mechanical Properties

| Alloy | Tensile Strength | Yield Strength | Elongation |

| 3003 | 145-195 MPa (21,000-28,000 psi) | 115-165 MPa (17,000-24,000 psi) | 10% to 20% |

Applications

3003 aluminum containers find applications in various industries due to their excellent properties. Some common applications include:

- 1. Food Packaging

3003 aluminum containers are widely used for food packaging, such as in the production of cans, trays, and containers for storing and transporting food. They are used in the packaging of processed foods, fruits, vegetables, meats, beverages, and more.

- 2. Beverage Cans

Aluminum cans made from 3003 alloy are commonly used for packaging carbonated and non-carbonated beverages. They offer lightweight, durable, and recyclable solutions for the beverage industry.

- 3. Cookware

3003 aluminum alloy is popularly used in the production of cookware, including pots, pans, and baking trays. Its excellent heat conductivity ensures even cooking and heat distribution.

- 4. Household Containers

3003 aluminum containers are utilized in various household applications, such as storage containers, lunch boxes, and take-out containers. They provide a lightweight and convenient solution for storing and transporting food.

- 5. Pharmaceutical Packaging

Due to its corrosion resistance and hygienic properties, 3003 aluminum containers are used in the pharmaceutical industry for packaging medications, tablets, capsules, and other pharmaceutical products.

- 6. General Purpose Containers

The versatility of 3003 aluminum alloy makes it suitable for a wide range of general-purpose containers. These containers can be used for storage, organization, and transportation in industries such as cosmetics, chemicals, automotive, and more.

The excellent formability, corrosion resistance, lightweight nature, and recyclability of 3003 aluminum container make it a popular choice for various packaging and container applications across different industries.

Compare to 8011 Aluminum

Differences between 8011-O and 3003 aluminum foil used for making food containers:

- Strength and Hardness: 3003 aluminum foil has higher strength and hardness compared to 8011-O aluminum foil. This means that 3003 aluminum foil may be stronger and more suitable for applications that require higher strength and resistance to deformation.

- Corrosion Resistance: Due to its copper content, 3003 aluminum foil has better corrosion resistance, particularly in acidic and alkaline environments. While 8011-O aluminum foil also has good corrosion resistance, it may be slightly inferior to 3003 aluminum foil in specific corrosive conditions.

- Application of Food Containers: Both 8011-O and 3003 aluminum foils are widely used for food container manufacturing. 8011-O aluminum foil is commonly used for making disposable food containers, take-out containers, and oven food packaging. On the other hand, 3003 aluminum foil is often used for making more durable and reusable food containers, such as those used in hotels and restaurants.

- Processability: Both 8011-O and 3003 aluminum foils have good processability and can undergo folding, forming, and cutting processes. However, due to its higher strength, 3003 aluminum foil may require more force and processing techniques to achieve specific container shapes.

- Cost and Price: The cost and price of 8011-O and 3003 aluminum foils are influenced by market dynamics, raw material costs, and other factors. In general, 3003 aluminum foil may be relatively more expensive due to its higher strength and corrosion resistance properties.

Product & Packaging Photos

Why Choose Us

Yongsheng Aluminum is a leading aluminum products manufacturer&supplier in China with 25 years of export experience. Our outstanding product quality, price, and always on-time delivery has won us many long term partners and gained a great reputation worldwide. We provide one-stop product solution for both CC&DC aluminum products.

Contact us to get your quotation.

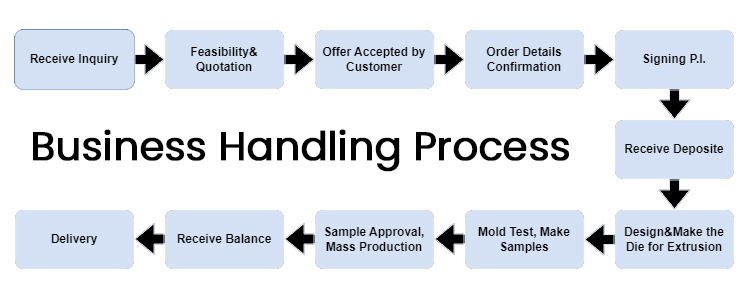

Business Handling Processes