8011-O Aluminum Container

The 8011-O Aluminum Container is a commonly used food container alloy, the 8011-O aluminum container provides a convenient, safe, and hygienic solution for food packaging. It is widely utilized in the food industry for applications such as take-out meals, fast food containers, and bakery packaging.

Henan Yongsheng Aluminum Co., Ltd. is situated in Gongyi City, Henan Province’s industrial area. Yongsheng is a 25-year-old aluminum foil manufacturer. Production and development of aluminum goods are the main priorities of our factory. With 3200 workers, the factory occupies 780,000 square meters.

8011-O Aluminum Container

The 8011-O aluminum foil is highly favored in various industries, particularly in food packaging, thanks to its outstanding malleability, allowing for easy folding, shaping, and forming of containers. Its flexibility and adaptability make it an excellent option for producing aluminum foil containers of different sizes and shapes.

While 3003 alloy boasts higher strength and corrosion resistance, it is more suitable for manufacturers with specific requirements due to its higher production cost.

Compared to states such as 8011-H14, 8011-H16, and 8011-H18, 8011-O aluminum foil is softer and more flexible, making it suitable for applications that require higher flexibility and easy shaping.

8011-O Aluminum Container provide excellent sealing performance, effectively preserving the freshness, flavor, and hygiene of the packaged food items. With its lightweight nature and recyclability, the 8011-O aluminum foil contributes to convenient handling, transportation, and environmental sustainability. Whether used in take-out meals, fast food containers, or bakery packaging, the 8011-O aluminum foil demonstrates its reliability and efficiency as a preferred choice for food packaging needs.

Product Parameter

|

Alloy |

1xxx Series: 1050, 1060, 1070, 1100, 1235 |

| 3xxx Series: 3003, 3004 | |

| 5xxx Series: 5052 | |

| 8xxx Series: 8011, 8021, 8079 |

| Thickness | 0.03-0.2mm |

| Capacity | ≥100ml |

| Shape | Square, Rectangular, Round, Customizable |

| Size | 200+ Type of Sizes |

| Applications | Cooking, Freezing, Baking and More |

Product Properties

8011-O Aluminum Chemical Properties

| Element | Composition (%) |

| Aluminum (Al) | 99.0 min |

| Silicon (Si) | 0.6 max |

| Iron (Fe) | 0.7 max |

| Copper (Cu) | 0.05-0.20 |

| Manganese (Mn) | 0.05 max |

| Magnesium (Mg) | 0.05 max |

| Zinc (Zn) | 0.10 max |

| Titanium (Ti) | 0.08 max |

| Chromium (Cr) | 0.05-0.25 |

| Other Elements | 0.15 max each |

| Total Others | 0.10 max |

8011-O Aluminum Physical Properties

| Property | Value |

| Density | 2.71 g/cm³ |

| Melting Point | 660°C (1220°F) |

| Electrical Conductivity | 35% (IACS) |

| Thermal Conductivity | 190-220 W/m·K |

| Coefficient of Thermal Expansion | 23.5 x 10^-6/K |

| Tensile Strength | 70-110 MPa (10,000-16,000 psi) |

| Yield Strength | 30-60 MPa (4,000-8,500 psi) |

| Elongation | 20% and 30% |

| Modulus of Elasticity | 70 GPa (10,000 ksi) |

| Hardness (Brinell) | 30 HB |

Applications

8011-O Aluminum Alloy’s malleability, corrosion resistance, and formability make it widely used in various fields. In addition to aluminum foil containers, it is also used in:

- Packaging materials

8011-O Aluminum Container’s high malleability and excellent sealing performance make it an ideal choice for food and beverage packaging. It is widely used in the production of aluminum containers for food packaging, pharmaceutical packaging, cosmetic packaging, tobacco packaging, and more.

- Heat exchanger fins

Due to its excellent thermal conductivity and corrosion resistance, 8011-O aluminum alloy is extensively used in the manufacturing of heat exchanger fins, such as those found in air conditioners, refrigerators, automotive radiators, and more.

- Building materials

The adaptability of 8011-O aluminum alloy is extensive, and it can be used to produce roofing, eaves, exterior wall panels, and other building materials. It offers advantages such as lightweight, durability, and corrosion resistance.

- Automotive components

The high strength and good formability of 8011-O aluminum alloy make it an important material in the automotive industry. It can be used to manufacture automotive body panels, roofs, doors, and other components.

- Electronic products

8011-O aluminum alloy also finds applications in the field of electronic products, such as the production of battery casings, enclosures for electronic components, and more.

Compared to other states of 8011 aluminum alloy

8011-O and other states of 8011 aluminum alloy have different characteristics.

- 8011-O Aluminum Container

8011-O refers to the annealed state of the 8011 aluminum alloy. Annealing is a process that improves the ductility and malleability of the material by heating and controlled cooling. 8011-O is commonly used in applications that require high plasticity and formability, such as packaging materials, food packaging containers, pharmaceutical packaging, etc.

- 8011-H14, 8011-H16, and 8011-H18

These states indicate different levels of hardening of the 8011 aluminum alloy. Hardening is a process that increases the hardness and strength of the material while reducing its ductility and formability through cooling and processing. Therefore, these states of 8011 are used in applications that require higher strength and rigidity, such as can bodies, construction materials, automotive components, etc.

Compared to 3003 Aluminum Container

- Chemical Composition

8011-O alloy typically contains about 0.05-0.30% iron, 0.6-1.0% silicon, 0.1% copper, 0.2% manganese, as well as trace amounts of magnesium, chromium, and zinc. On the other hand, 3003 alloy usually contains about 1.0-1.5% manganese. The addition of manganese can enhance the hardness and strength of the alloy.

Due to the lower manganese content in the 8011 alloy, 3003 alloy generally exhibits slightly higher tensile strength and yield strength compared to 8011-O Aluminum Container. This makes 3003 alloy more suitable for applications requiring higher strength containers.

- Formability

Both 8011-O Aluminum Container and 3003 alloys have good formability and can be easily shaped into containers. They have similar processability and are suitable for manufacturing various aluminum containers.

- Corrosion Resistance

Both 8011-O Aluminum Container and 3003 alloys have good corrosion resistance and can resist corrosion from moisture and general environmental conditions.

- Application

8011-O alloy is widely used in food and beverage containers, aluminum foil, bottle caps, and other packaging applications. 3003 alloy is also commonly used for manufacturing food containers such as pots, cans, as well as general containers and packaging applications. The slightly higher hardness of 3003 alloy makes it more suitable for some demanding applications, providing better scratch resistance or higher structural strength.

Product & Packaging Photos

Why Choose Us

Yongsheng Aluminum is a leading aluminum products manufacturer&supplier in China with 25 years of export experience. Our outstanding product quality, price, and always on-time delivery has won us many long term partners and gained a great reputation worldwide. We provide one-stop product solution for both CC&DC aluminum products.

Contact us to get your quotation.

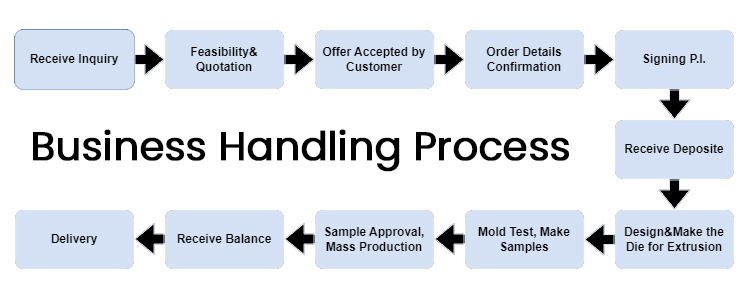

Business Handling Processes