Aircraft Aluminum Sheet

Aircraft aluminum sheets are widely used in the aerospace field due to their unique advantages such as low density, moderate strength, easy processing and forming, strong corrosion resistance, rich resources, and strong recyclability. The skin, beams, ribs, stringers, bulkheads and landing gear on the aircraft can all be made of aluminum alloy. The crew cabin, front fuselage, middle fuselage, rear fuselage, vertical tail, flaps, elevators of the space shuttle The ailerons and horizontal tail are made of aluminum alloy.

Aircraft Aluminum Sheet Introduction

Aircraft aluminum sheets have good mechanical and processing properties, good plasticity after solution treatment, and good heat treatment strengthening effects. They generally have high strength and good toughness below 150°C (or even higher), making them ideal aviation structural materials. Mainly used in aviation industry design and manufacturing.

Aluminum alloys used in aircraft structures are mainly high-strength 2 series (2024, 2017, 2A12, etc.) and ultra-high-strength 7 series (7075, 7475, 7050, 7A04, etc.), and some 5 series (5A06, 5052, 5086, etc.) and 6 series (6061, 6082, etc.) and a small amount of other series aluminum materials.

Aircraft Aluminum Sheet Specifications

| Name |

Aircraft Aluminum Sheet

|

| Alloy | 2000 series, 7000 series, 5000 series, 6000 series, etc |

| Temper | H14, H22, H32, T3, T4, T8, T651, etc |

| Thickness | 0.2-350mm |

| Width | 500-2300mm |

| Length | Customized |

| Packaging | Wooden pallet, wooden box |

| MOQ | 1 Ton |

| Sample | Free |

| Delivery Time | 7-25 days after order confirmation |

| Standards | GB/T 33227-2016、JIS H4000、ASTM B209、EN 485 |

| Price Terms | FOB, CIF, CFR, CNF, etc. |

Aluminum alloy application grades and heat treatment temper of aircraft in the aviation field

| Alloy Grade | Typical Properties | Applications | Main Tempers |

| 1420 | Low density and good corrosion resistance | Fuselage skin and stringers, cockpit, fuel tanks, hatch covers, floors, wing ribs, duct attachments. | – |

| 2024 | High strength, certain corrosion resistance and good overall performance. | Aircraft skins, frames, ribs, propellers and other aircraft structural parts. | T351, T4, T851 |

| 2219 | It has high room temperature strength and high temperature lasting strength, good thermoplasticity, no extrusion effect, weldable, and good corrosion resistance. | Aircraft skins and structural parts. | T31, T37, T87, T851, T3511 |

| 2324 | High strength and toughness | Aircraft structural components | T39 |

| 2524 | High strength, high toughness, high fatigue resistance | Fuselage skin | T3 |

| 3003 | Good corrosion resistance and ductility, low density | Engine filter | H22 |

| 5052 | Medium strength, good corrosion resistance and weldability, easy to process and shape | Fan blades, oil storage tank | H32, H34, H112 |

| 7050 | High strength, good fracture toughness, low quenching sensitivity | Aircraft fuselage frame, wing skin, bulkhead, stiffeners, ribs, brackets, landing gear support parts, seat rails. | T7651, T7451, T73511, T76511, T7452 |

| 7150 | High strength, excellent corrosion resistance, excellent fracture properties and fatigue resistance | The aircraft’s upper wing structure, fuselage plate beam flange, upper outer panel main wing longitudinal beam, and fuselage reinforcements. | T651, T7751, T6511, T77511,T77 |

| 7175 | High strength, good corrosion resistance, excellent fracture performance | Aircraft outer wing spar, main landing gear, nose gear action tube, vertical tail joint | T74, T7452, T76511 |

| 7475 | High-strength forged aluminum alloy, high comprehensive performance, suitable for large-section products | Aircraft fuselage, wing skin, center wing structural parts, wing spars, bulkheads, partitions, helicopter decks, landing gear doors | T61, T761, T651, T7651, T7351 |

| 7085 | High-strength forged aluminum alloy, high comprehensive performance, suitable for large-section products | Stringers | T7651 |

Common Aircraft Aluminum Sheet

2024: This alloy is known for its high strength-to-weight ratio and excellent fatigue resistance. It is commonly used on aircraft structural components such as wing and fuselage skins, bulkheads and wing ribs.

6061: This alloy has good corrosion resistance and moderate strength. It is commonly used in aircraft parts that require both structural strength and machinability, such as aircraft accessories, brackets and panels.

7075: This alloy has excellent strength and is often used in applications requiring high strength and hardness. It is used in areas such as aircraft wing spars and structural parts that need to withstand high loads.

5052: This alloy has good corrosion resistance, formability and weldability. Used for aircraft fuel tanks, fuel tanks and other structural components that need to withstand harsh environments.

7475: This alloy is known for its high strength and excellent fracture toughness. It is commonly used in aerospace applications including aircraft wing skins and structural components.

7050: This alloy has high strength and good resistance to stress corrosion cracking. It is commonly used in aircraft wing structures, fuselage frames and bulkheads.

Aircraft Aluminum Sheet Applications

2024 aviation aluminum sheet is used for aircraft structural parts. 2048 aviation aluminum sheet is mainly used to manufacture aerospace vehicle structural parts and weapon structural parts. 2218 is mainly used for aircraft engine and diesel engine pistons, aircraft engine cylinder heads, jet engine impellers and compressor rings. 2219 is used in space rocket welding oxidizer tank, supersonic aircraft skin and structural parts.

7049 is used for aircraft and missile parts, such as landing gear hydraulic cylinders and extrusions. 7050 aviation aluminum alloy is used in medium and thick plates, extrusions, free forgings and die forgings of aircraft structural parts. 7178 aviation aluminum sheet is used to manufacture parts of aerospace vehicles that require high compressive yield strength. 7475 aircraft aluminum sheets is used for fuselage plates, wing frames, stringers, etc. 7A04 is used for aircraft skins, screws, and stress-bearing components such as beam stringers, bulkheads, wing ribs, and landing gear.

Aircraft Aluminum Sheets Advantages

1. High strength, much better than mild steel, and compact structure;

2. After solid solution treatment, its plasticity is better; the heat treatment strengthening effect is good;

3. Good mechanical properties;

- High temperature: As the temperature increases, the strength of the alloy decreases, and the strength is high at room temperature.

- Low temperature: The alloy has particularly good low-temperature strength and toughness. In liquid nitrogen at -196°C, the alloy’s strength and toughness are still very high;

4. It has good cutting performance under heat treatment strengthening state and good wear resistance;

5. It has good anti-corrosion and anti-oxidation properties, but has a tendency of stress corrosion cracking;

6. The welding performance is poor and cracks are prone to occur during welding. It cannot be fusion welded, but it can be contact welded by strong pulse current.

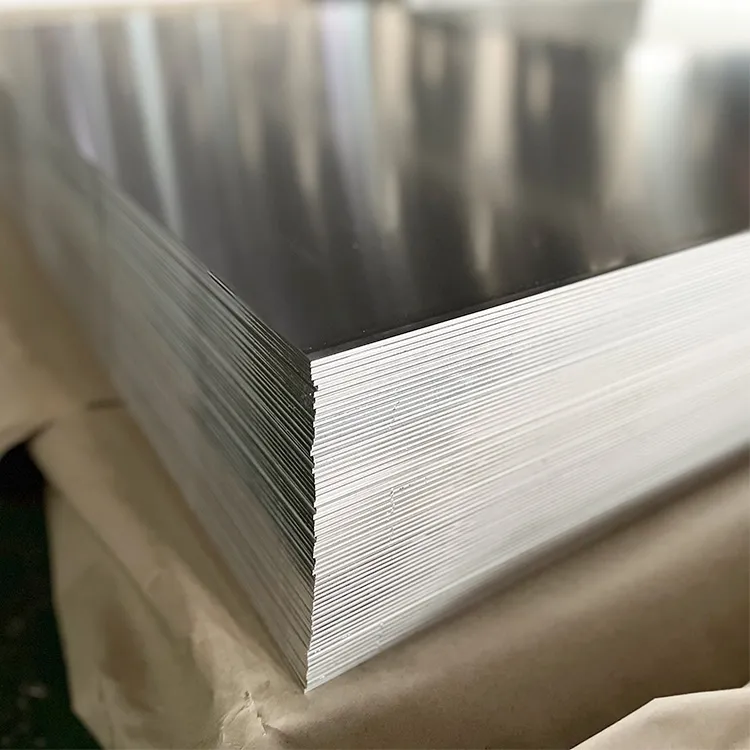

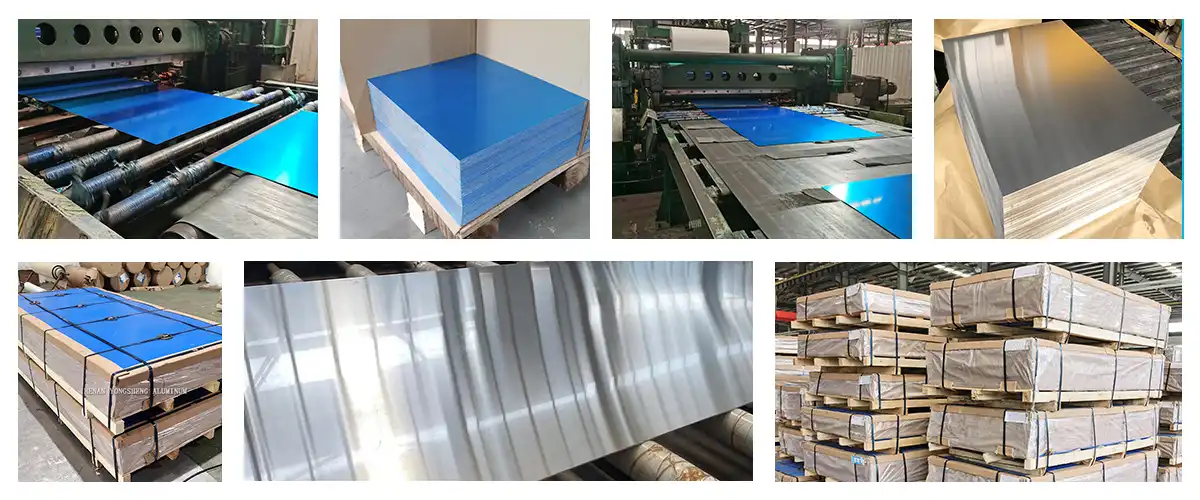

Product & Packaging Photos

Why Choose Us

Yongsheng Aluminum is a leading aluminum products manufacturer&supplier in China with 25 years of export experience. Our outstanding product quality, price, and always on-time delivery has won us many long term partners and gained a great reputation worldwide. We provide one-stop product solution for both CC&DC aluminum products.

Contact us to get your quotation.

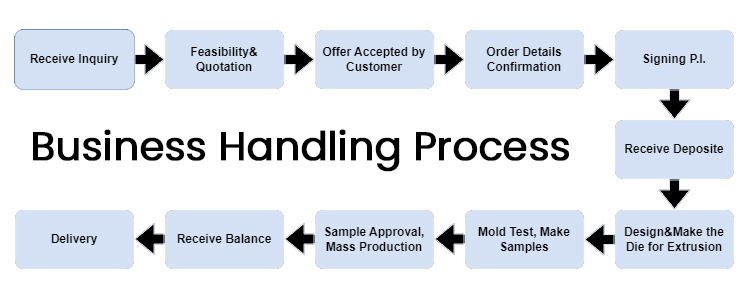

Business Handling Processes