Aluminum Circle For Lampshade

Alloy 1050 aluminum is commonly chosen as a material for lampshades. 1050 aluminum circle offers a combination of desirable properties such as reflectivity, electrical conductivity, corrosion resistance, formability, lightweight, and cost-effectiveness, making it a popular and practical choice for lampshade materials

Yongsheng Aluminum factory covers 780,000 square meters has 27 production lines, 32 punch presses, 10 CNC lathes etc. We focus on aluminum sheet/coil, aluminum foil, aluminum strip, aluminum circle, color-coated aluminum, embossed aluminum, aluminum checker sheet, mirror aluminum sheet etc. The annual output reaches 300,000 tons and continuing expanding.

Product Introduction

The 1050 series aluminum circle is a commonly used alloy for pressure cookers due to its excellent characteristics including strength, formability, corrosion resistance and weldability. The 3000 series aluminum alloys are a group of wrought aluminum alloys primarily composed of aluminum (Al) and manganese (Mn). The most common alloy in this series is 3003, which is widely used in various applications, including pressure cookers.

Specifications

| Alloy | 1050/1060/1070/1100 |

| Temper | O/H14/H18 |

| Diameter | 100mm (4 inches) to 600mm (24 inches) or more |

| Thickness | 0.5mm (0.02 inches) to 2mm (0.08 inches) |

| Size | Size can be customized |

| Delivery Time | Ready stock 7-10 days |

| MOQ | 1 ton |

| Loading Port | Qingdao Port, Tianjin Port, Shanghai port. |

| Price Terms | FOB, CIF, CFR, CNF, etc. |

| Quality Control | Mill Test Certification is supplied with shipment, Third Part Inspection is acceptable. |

Aluminum Circle For Pressure Cooker

Alloy 1050 offers a combination of desirable properties such as reflectivity, electrical conductivity, corrosion resistance, formability, lightweight, and cost-effectiveness, making it the most popular and practical choice for lampshade materials.

Alloys 1060, 1070, and 1100 are also commonly used for lampshades.

Alloy 1060:

- Alloy 1060 is a pure aluminum alloy with excellent electrical conductivity and thermal conductivity.

- It has good formability and can be easily shaped into desired lampshade designs.

- Lampshades made from alloy 1060 are lightweight and corrosion-resistant.

- However, compared to other alloys, it may have slightly lower strength and hardness.

Alloy 1070:

- Alloy 1070 is another pure aluminum alloy with high electrical conductivity and corrosion resistance.

- It has similar properties to alloy 1060, including good formability and lightweight characteristics.

- Lampshades made from alloy 1070 are known for their excellent reflectivity and heat dissipation capabilities.

Alloy 1100:

- Alloy 1100 is a commercially pure aluminum alloy with high corrosion resistance and good formability.

- It has excellent reflectivity and thermal conductivity properties, making it suitable for lampshade applications.

- Lampshades made from alloy 1100 are lightweight, durable, and resistant to rust and oxidation.

Alloys 1060, 1070, and 1100 are frequently chosen for lampshades due to their high purity, electrical conductivity, corrosion resistance, and formability. These alloys offer a combination of desirable properties that make them suitable for creating functional and aesthetically pleasing lampshades.

Product Advantages

Alloy 1050 from the 1 series is the most popular choice for lampshade due to its high purity, reflectivity, and corrosion resistance.

- High-purity aluminum: Alloy 1050 is a high-purity aluminum alloy with an aluminum content exceeding 99%. This gives it excellent electrical conductivity and thermal conductivity.

- Excellent reflectivity: Alloy 1050 exhibits good reflectivity, allowing it to maximize light reflection. This enables aluminum lampshades to efficiently focus and provide bright illumination.

- Outstanding corrosion resistance: Alloy 1050 possesses excellent corrosion resistance, offering good resistance to corrosion in most common environmental conditions. This helps aluminum lampshades maintain their appearance and performance over extended periods of use.

- Easy formability: Alloy 1050 has good formability and can be easily shaped into the desired lampshade form through processes like cold working and hot working. This provides manufacturers with flexibility in designing and manufacturing various unique lampshade designs.

- Lightweight and durable: Alloy 1050 has a low density, making finished aluminum lampshades lightweight. Despite this, it still maintains sufficient strength and durability to withstand the stresses of daily use and handling.

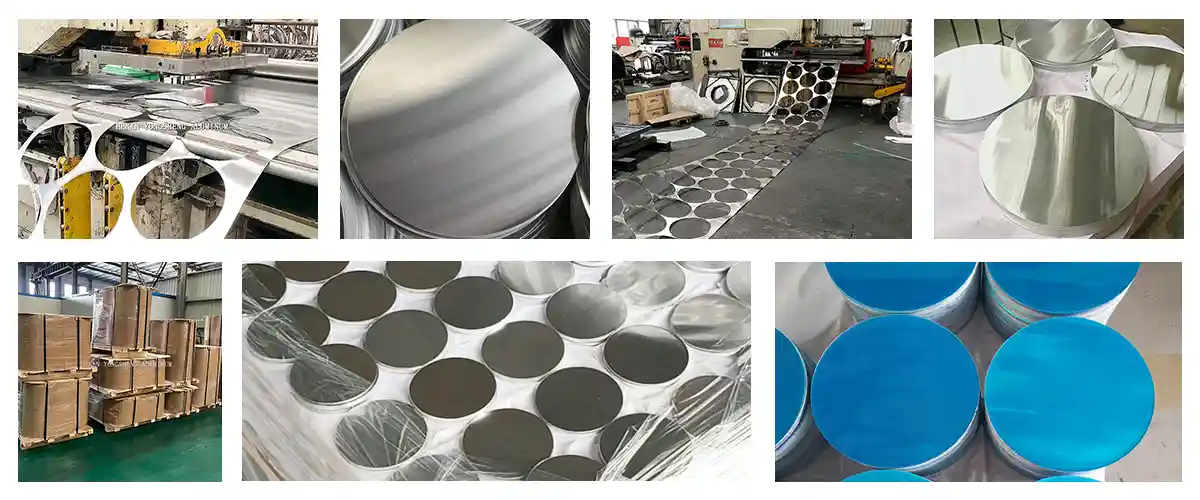

Product & Packaging Photos

Why Choose Us

Yongsheng Aluminum is a leading aluminum products manufacturer&supplier in China with 25 years of export experience. Our outstanding product quality, price, and always on-time delivery has won us many long term partners and gained a great reputation worldwide. We provide one-stop product solution for both CC&DC aluminum products.

Contact us to get your quotation.

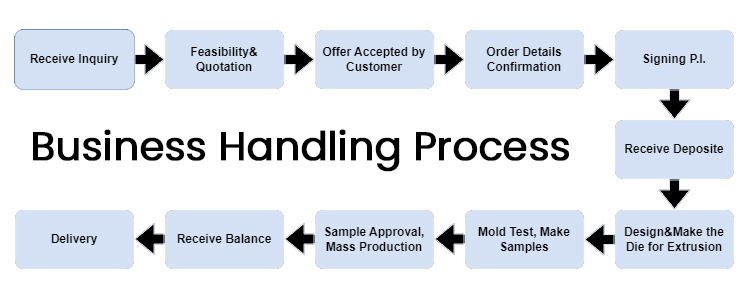

Business Handling Processes