Aluminum Foil for Honeycomb Core

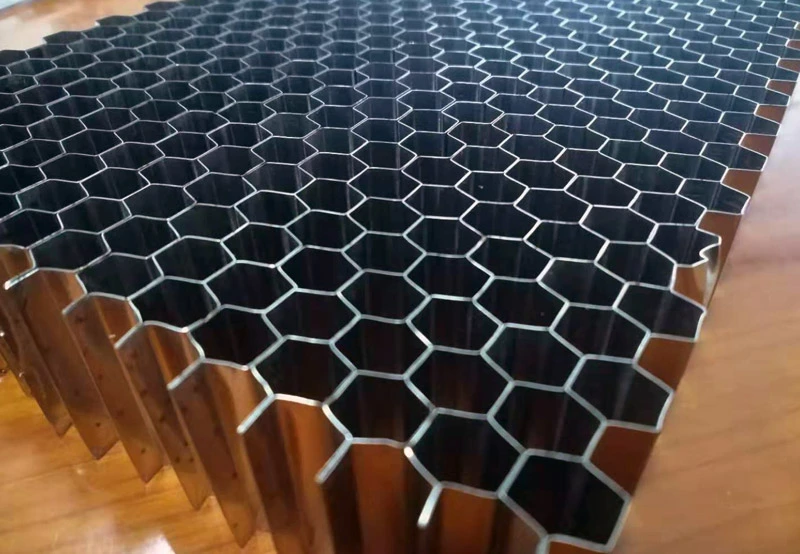

Aluminum foil for honeycomb core, also referred to as Honeycomb aluminum foil, is a lightweight core material composed of two layers of aluminum foil that are fused together to form a pattern of hexagonal cells, resembling a honeycomb. Henan Yongsheng Aluminum is a reputable manufacturer of high-quality honeycomb aluminum foil. Situated in the industrial hub of Gongyi City, Henan Province, our factory boasts 18 years of experience in producing and developing various aluminum products, including aluminum sheets, coils, foils, strips, color-coated aluminum sheets, coils, aluminum circles, embossed aluminum, aluminum checker plates, mirror aluminum plates, anti-skid aluminum plates, and more. Spanning an impressive area of 300,000 square meters, our facility is staffed by 3,200 dedicated employees.

Product Introduction

Aluminum foil for honeycomb core finds widespread application across various industries, including aerospace, aviation, marine, naval, construction, and architecture. Its combination of lightweight composition and exceptional strength makes it a highly desirable material for sandwich panels. These panels consist of a honeycomb aluminum core that is bonded between two outer layers of materials like fiberglass or carbon fiber. Aluminum foil for honeycomb core is particularly valued for its ability to provide structural support while minimizing weight. Moreover, aluminum foil for honeycomb core exhibits excellent soundproofing and vibration-damping characteristics, further enhancing its utility in different contexts. It is commonly used in the manufacturing of speaker grills, acoustic panels, and industrial enclosures, where its properties help to mitigate noise and vibrations effectively. Commonly used alloys in aluminum foil for honeycomb core include 3003, 3004, 3104 and 5052, known for their favorable strength, formability, and corrosion resistance properties.

Specifications

| Alloy | 3003/3004/3104/5052 |

| Width | H18/H19 |

| Thickness | 20-100um |

| Width | 90-1500mm, common 914/1020mm |

| Surface Technology | Pickling+water washing+silane passivation+epoxy varnishes |

| Price term | EXW,FOB,CIF,CFR,CNF,etc. |

| Payment | L/C,T/T,Western Union,etc. |

| Certificates | ISO9001&GS&ROHS&FDA&TUV&ISO&GL&BV,etc. |

Product Application

When comparing the aluminum alloys 3003, 3004, 3104, and 5052 for honeycomb cores, several factors come into play. 5052 stands out with its higher strength and superior corrosion resistance, making it suitable for load-bearing applications in harsh environments. On the other hand, 3003, 3004, and 3104 offer excellent formability and cost-effectiveness, making them a viable choice for shaping complex honeycomb structures within budget constraints. Weldability is generally good for all alloys, although 5052 may require more specialized techniques. In summary, the alloy choice depends on the specific requirements of the application, with 5052 favored for strength and corrosion resistance, and 3003, 3004, and 3104 preferred for formability and cost-effectiveness.

Product Advantages

Excellent board flatness – superior board shape

Utilizing a real-time shape controller and implementing a subsequent straightening process with secondary shape correction, we ensure that the aluminum foil maintains a high-quality shape, resulting in exceptional layout and precise shape accuracy.

Exceptional strength – minimal post-processing deformation

By using 3003-h18 aluminum foil as the base material for the honeycomb core, we achieve remarkable strength, leading to minimal deformation of the finished product. The end surface remains flat, free from burrs, and the board surface maintains a high level of flatness even after bonding and lamination.

Degreased and pristine aluminum foil surface – enhanced adhesive durability

Through the utilization of specialized degreasing equipment and a passivation process, we ensure that the surface of the aluminum foil is thoroughly cleansed of oil. This process enhances the adhesion strength, preventing the glue from easily detaching and ensuring a long-lasting service life.

Production Process

- Aluminum foil with a passivated surface is coated with a node glue, specifically an epoxy modified high-temperature curing glue.

- The aluminum foil is precisely sliced based on the intended size, stacked (the number of layers depends on the desired height of the final honeycomb core), fused together at high temperatures, and then cut into individual pieces, forming a hexagonal honeycomb structure.

- The inner side of the bottom plate is coated with adhesive, the honeycomb core is carefully positioned on it, and then adhesive is applied to the inner side of the panel, which is then placed on top of the honeycomb core.

- The assembly undergoes hydraulic solidification, followed by cooling and cutting processes to achieve the final product.

Product & Packaging Photos

Why Choose Us

Yongsheng Aluminum is a leading aluminum products manufacturer&supplier in China with 25 years of export experience. Our outstanding product quality, price, and always on-time delivery has won us many long term partners and gained a great reputation worldwide. We provide one-stop product solution for both CC&DC aluminum products.

Contact us to get your quotation.

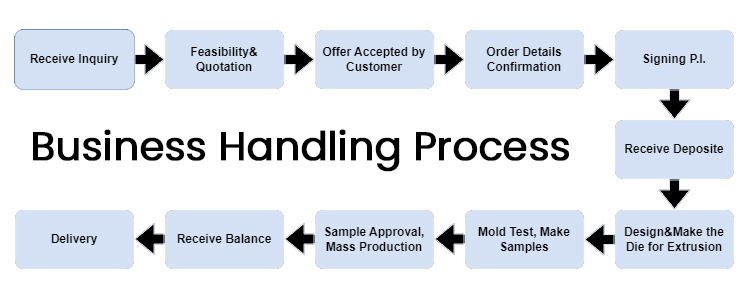

Business Handling Processes