Embossed aluminum is a versatile and strong material widely used in various industries due to its superior strength, durability and aesthetics. These boards are designed with a unique pattern that enhances grip and provides anti-slip properties, making them ideal for applications where stability is critical. In this article, we will explore several common types of embossed aluminum, their patterns, applications, and benefits. By understanding the characteristics of each type, you will be better able to choose the most suitable embossed aluminum for your specific needs.

Characteristics Of Embossed Aluminum

- Enhanced durability

- Impact resistance

- Prevent wear and tear

- Longevity in harsh environments

- Heat insulation

- Thermal reflectivity

- Insulating properties

- Building energy efficiency

Common Uses Of Embossed Aluminum:

Transportation Industry

Embossed aluminum plates can be used to make subway car walls, partitions, etc.; car panels, car interiors; ground markings such as runways, aprons and taxiways, and can even be used for high-speed rail sound protection barriers.

Packaging and Labeling

In the packaging industry, for example, embossed aluminum foil is often used to package chocolate, candy, coffee, pills, capsules, tablets, cigarettes and other products.

HVAC Systems and Insulation

Embossed aluminum coils with a thickness of 0.3mm-1.0mm are commonly used as heat-reflective insulation barrier materials for HVAC systems. It can be used as an insulation layer for cold water pipes, wrapping pipes and air ducts, and can be matched with insulation materials such as glass wool, foam plastic or rock wool to provide better insulation.

Building Exterior Wall Insulation

Commonly used embossed 3003 and 3004 aluminum plates with thicknesses between 1.0mm and 3.0mm are often compounded with wood, steel, gypsum boards, polymers and other materials, and are used for doors, windows, interior and exterior walls, and facades etc.; embossed aluminum foil can be used as insulation layer of building exterior walls, exterior wall decoration, etc. to reduce the temperature difference between the inside and outside of the building and improve the appearance.

Embossed Aluminum Classified By Aluminum Alloys:

- Ordinary aluminum alloy embossedaluminum: This type of embossed aluminum is processed on the basis of 1000 series aluminum sheet plate(such as 1060 aluminum sheet). It is low in price and has good adaptability. It can be used in humid and cold environments such as packaging industry and cold storage. .

- Aluminum-manganese alloy embossed aluminum: This type of embossed aluminumis based on 3000 series anti-rust aluminum plate(such as 3003 aluminum), so its strength is higher than ordinary alloy aluminum plate, and it has anti-rust properties. It is usually used in some humid and cold places. Environments where rust prevention is required.

- Aluminum-magnesium alloy embossed aluminum: This type of embossed aluminum is made of 5000 series aluminum plate(often used 5052 aluminum plate, 5083 aluminum plate etc.) as raw material. It has good anti-corrosion properties and high hardness. It is usually used in ships and other environments that require anti-rust, anti-corrosion and load-bearing capacity.

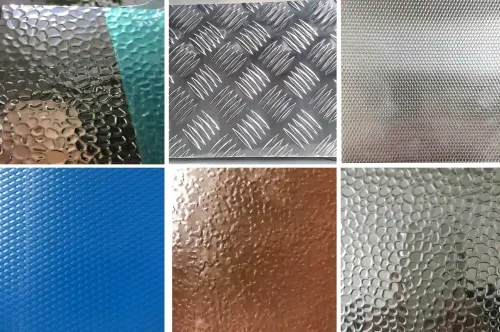

Types of Popular Embossed Aluminum

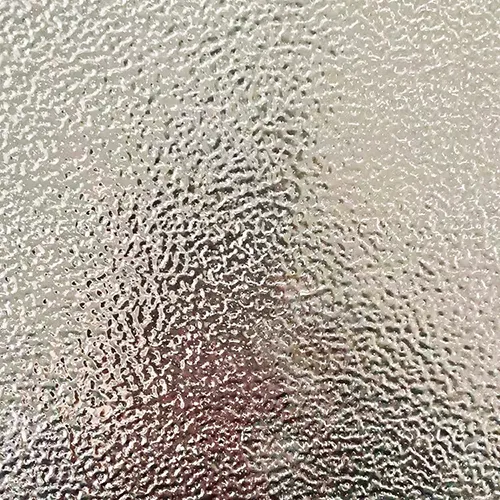

1.Orange Peel Embossed Aluminium Plate

Orange peel embossed aluminum sheet, also known as stucco embossed aluminum, refers to an aluminum sheet material with an orange peel-like texture. It presses an alloy aluminum plate to give the surface an orange peel-like texture pattern, thereby increasing the decorativeness and special touch of the aluminum plate. High-purity aluminum alloy plates are used as raw materials, and the appropriate size and thickness are determined according to product requirements. The aluminum plate is first cleaned, degreased and deoxidized to ensure good coating adhesion and weather resistance, and then a special orange peel texture roller or pattern mold is used to press the aluminum plate at a certain temperature and pressure to make the surface form a similar Texture pattern of orange peel. The embossed aluminum panels are then cut and shaped as needed to meet the customer’s size and shape requirements.

Orange peel embossed aluminum plates find extensive applications in the automotive sector, interior design, architecture, and manufacturing. Common uses include house décor, ceilings, interior partitions, and outdoor wall decorations.

2. Bean Pattern Embossed Aluminum

Bean pattern embossed aluminum is a type of aluminum plate sheet with a raised bean-like creation embossed on the surface. It’s also a standard anti-slip aluminum sheet. Typically used for anti-skid carriages, platforms, anti-skid cold storage floors, anti-skid workshop floors, anti-skid elevators, and so on. YSA bean-shaped embossed aluminum retains the toughness and corrosion resistance of regular aluminum alloys and is available in a number of alloy grades, diameters, and thicknesses.

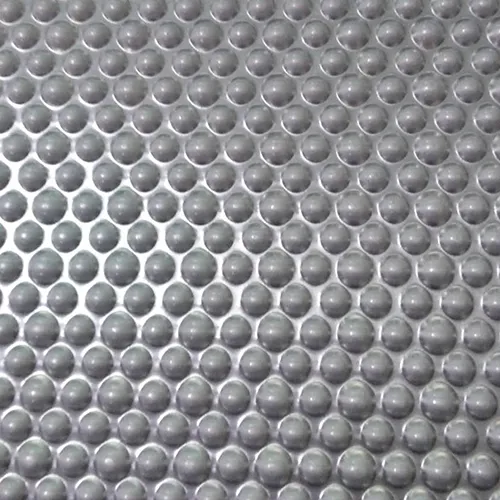

3. Spherical Embossed Aluminum

Spherical embossed aluminum is an aluminum plate with fine spherical patterns on its surface, also known as hemispherical striped aluminum sheet. Mainly used for outer packaging boxes, the compressive strength of this type of aluminum sheet is much higher than other series of aluminum pattern plates.

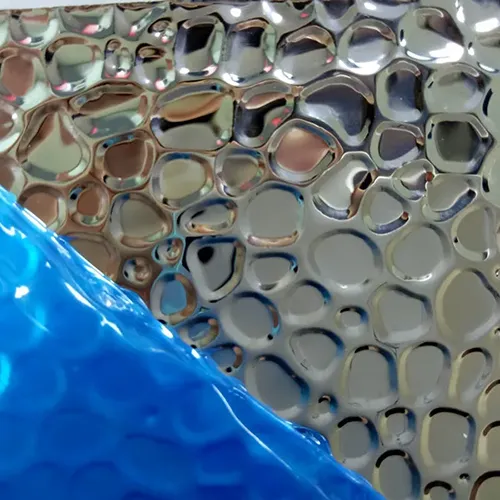

4. Cobble Aluminum Embossed Sheet

Cobble/Pebble aluminum embossed sheet is a decorative aluminum sheet with a unique concave and convex pattern. Pebble embossed sheets are very lightweight, have excellent corrosion resistance and aesthetics, and are often used in indoor and outdoor wall decoration, ceilings, furniture production and other fields.

5. Pointer Embossed Aluminum Sheet

Pointer aluminum pattern plate is a non-slip aluminum plate with pointer pattern, which has the same practical effect as five-rib embossed aluminum plate. Mainly used for anti-slip in carriages, service platforms, cold storage floors, workshop floors and elevator cars. If you pay attention to practical life, it is recommended to consider 5052 and 6061 pointer embossed aluminum plates, which have excellent rust and corrosion resistance.