Aluminum sheets are widely used in the construction field because of their light weight, processability, corrosion resistance and other excellent properties. Aluminium sheets are the most widely used in construction and are often used to manufacture curtain walls, roofs, ceilings, doors and windows, etc.

1000 series aluminum and 3000 series aluminum are frequently used in the construction field because of their price advantages. Due to the low strength of pure aluminum alloy, it can only be used in places where strength requirements are not high in the construction field. Therefore, the most commonly used ones are 3000 series, such as 3003 aluminum sheet, 3004 aluminum sheet, 3105 aluminum sheet, etc. The following will give you a detailed introduction to the four major uses of aluminum alloy sheets in building and construction industry:

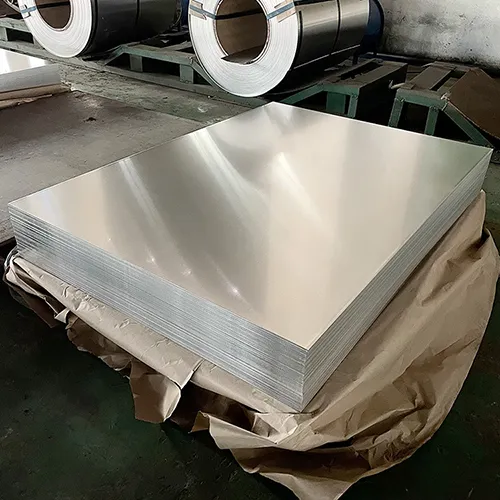

Various Aluminum Sheet Plate

In the construction industry, different types of aluminum sheets are available to meet specific requirements. Ordinary aluminum sheets have a smooth surface, clean and stylish appearance, and are suitable for various architectural designs; embossed aluminum sheets provide enhanced beauty and improved grip, making them suitable for flooring and decorative applications; anodized aluminum sheets are electrochemically treated, thereby improving resistance Corrosive and available in a variety of colors; perforated aluminum plates feature regularly spaced holes for good ventilation and can be used on exterior walls for barrier and shielding applications.

4 Usages Of Aluminum Sheet In Building Industry:

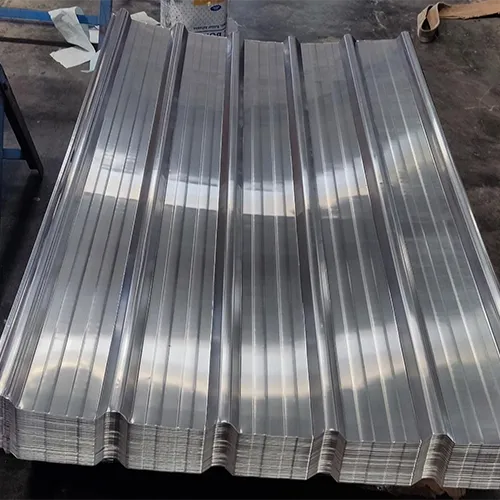

Corrugated Aluminum Sheets For Outdoor Roofs

Outdoor roofs often appear in the form of corrugated aluminum sheet. Aluminum corrugated sheets, also known as aluminum roofing sheet, is aluminum metal products made by machine forming or continuous bending. They are suitable for industrial and civil buildings. , warehouses, special buildings, roofs, walls, and interior and exterior wall decorations of large-span steel structure houses, etc. It has the characteristics of light weight, high strength, rich colors, convenient and quick construction, earthquake resistance, fire protection, rainproof, long life, and maintenance-free. Aluminum tiles are light in weight and easy to process and form. Aluminum alloy 3003 aluminum sheets and 5052 aluminum sheets are commonly used as raw materials for the production of roof sheets.

Aluminum Sheet for Curtain Wall

Aluminum sheets for curtain walls are commonly used in the 1000, 3000 and 5000 series, which have the characteristics of good rigidity, light weight and high strength. The curtain wall aluminum sheet adopts a process of processing first and then painting, which can extend the service life of the curtain wall and avoid powdering and corrosion. At the same time, it can be processed into various complex geometric shapes such as plane, arc, spherical and so on. This kind of aluminum plate for curtain wall is not easy to stain, easy to clean and maintain, and easy and fast to install and construct. Commonly used aluminum sheet metal alloys for curtain walls include 1050, 1060, 3003, 5052, etc., with thicknesses of approximately 1.5mm, 2.0mm, 2.5mm, and 3.0mm.

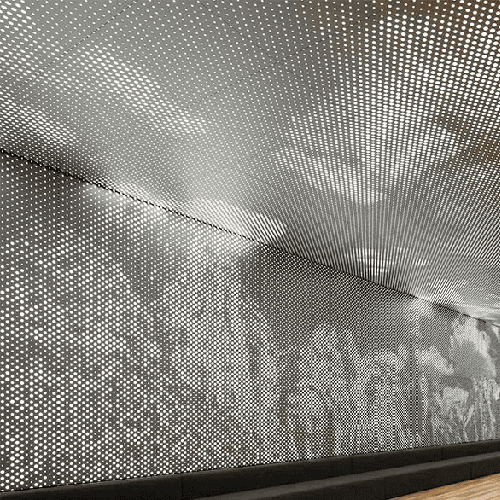

Indoor Aluminum Ceiling

Commonly used types of aluminum sheets for indoor aluminum ceilings include aluminum sheets, composite aluminum panels and perforated aluminum sheets. Among them, perforated aluminum sheets are widely used in interior decoration. Aluminum perforated sheets are made of high-standard pre-rolled aluminum alloy sheets as the main raw material and sheared by mechanical pressure. They have the characteristics of light weight, high temperature resistance, corrosion resistance, fire prevention, and beautiful appearance. Commonly used aluminum ceiling materials include 1000 series, 3000 series and 5000 series. 1000 series aluminum has lower strength, but is easy to process. As long as it reaches a certain thickness, it can basically meet the most basic flatness requirements of the ceiling. As for the aluminum-manganese alloy-3000 series, its strength is higher than that of the aluminum-magnesium alloy series, but its oxidation resistance is slightly lower than that of the 5xxx series aluminum alloy. If both sides are protected, the shortcomings of its anti-oxidation ability being not as good as that of aluminum-magnesium alloy will basically be solved. The best material should be 5000 series (commonly used 5052 aluminum sheet plate). This material has good oxidation resistance. At the same time, because of its manganese content, it has a certain strength and stiffness, making it the most ideal material for ceilings.

Aluminum Alloy Doors And Windows

The aluminum alloys used in aluminum doors and windows are mainly 6000 series, such as 6063 T5 aluminum and 6063 T6 aluminum. The latter is more common in some higher-priced door and window products. In terms of physical performance, T6 is better than T5 and 6063 A is better than 6063. However, for normal home use by consumers, there is no need to deliberately pursue higher quality aluminum profiles.

Is Aluminum Good for Building?

Stability:

The aluminum plate’s structure adheres to all architectural mechanical rules. It has stronger corrosion resistance than other materials and will not deform owing to moisture, shrink and soften due to sunlight, and become brittle due to freezing and ultraviolet rays.

Durability:

Through special surface treatment of aluminum alloy, the actual service life of aluminum doors, windows, curtain walls and other products is synchronized with the building.

Wind pressure resistance:

Aluminum alloy has good hardness, high tensile strength and high wind pressure resistance, making it suitable for high-rise buildings.

Ease of processing:

Aluminum sheet plates are flexible and easy to work with; they may be bent, folded, and cut to fit a variety of construction requirements. To increase construction efficiency, aluminum panels can also be prefabricated, swiftly assembled, and put on site.

Aesthetics:

Aluminum alloy has metallic luster, and aluminum metal products in hundreds of colors can be produced through oxidation coloring or electrostatic spraying and fluorocarbon spraying.

Environmental protection:

After use, aluminum sheets can be recycled and used again. Smelting results in a high recovery rate, whereas recycling uses little energy—roughly 5% of primary aluminum production. Each cycle results in a 3.5%–8.5% loss. Because it is recyclable, there is no need to squander resources or pollute the environment.

Anodized Aluminum Sheets—Emerging Building Materials

In recent years, anodized aluminum sheets, as an emerging material, have been used in many indoor and outdoor practices in Chinese buildings. Anodized aluminum plates have five major characteristics:

1. The metal appearance is protected by a transparent anodized film, so that the natural and soft metal texture of aluminum is fully retained;

2. Processability: Anodized aluminum has excellent processability, excellent forming and bending properties;

3. The surface is consistent. Facing various forms of buildings, anodized aluminum sheets are always uniform in color;

4. Corrosion resistance, because the anodizing process generates a dense oxide film on the metal surface, which has strong corrosion resistance and makes the building hardness and strength better;

5. It has strong weather resistance. Its surface is not charged and does not attract dust. It is easy to clean and remains as clean as new after repeated cleanings, making the building facades timeless. Today, the anodized aluminum plate project from 40 years ago is still the same;

6. Sustainability, and as a Class A non-combustible environmentally friendly material.