Aluminum foil has obvious differences in each segment, with a high degree of customization and a low degree of universality. One of them is battery foil. According to China Nonferrous Metals Processing Association (CNMPA), aluminum foil can be divided into packaging foil, air-conditioning foil, electronic foil, battery foil, and others, in addition to special brazing foil used in automotive thermal management systems. We will focus on battery foil, which is currently the most in demand.

Battery Foils-alloy, temper, thickness and surface treatment

Aluminum foils for lithium ion batteries are divided into: lithium foil positive electrode collector, aluminum foil for lithium battery packaging aluminum-plastic film, and aluminum foil for electrode lugs. Aluminum foil for lithium-ion battery positive electrode collector is commonly referred to as aluminum foil for battery.

On the one hand, it is the electrode of the collector, and on the other hand, it is the carrier of the lithium battery cathode material, that is, the lithium battery material should be coated on it. Battery aluminum foil is an important raw material for lithium battery production. Positive electrode consists of positive electrode lugs, high temperature tape, positive electrode collector aluminum foil and positive electrode material, and the thickness of positive electrode collector aluminum foil is about 0.016mm.

The technology content of aluminum foil for positive electrode collector of high-end power battery is relatively high. Aluminum foil for collector is mainly made of alloys such as 1060, 1070, 1100, 1235, 3003, etc. The mainstream thickness specification is 10-20 μm, and some battery manufacturers use 8 μm or even 6 μm. At the same time, the battery manufacturers have higher requirements for strength, so the production of aluminum foil for positive electrode of batteries is not so simple as it is imagined.

Aluminum foil is mainly divided into hot rolling and continuous casting, and the double-zero aluminum foil, general single foil, battery foil, etc. for general industrial use basically belong to the pure aluminum series, which is more suitable for continuous casting. Although the requirements of battery foil are significantly higher than those of ordinary 0.1mm aluminum foil, the production technology and process are basically the same. High-end products have a certain threshold. The tensile strength Rm of general grade battery foil is between 150 N/mm2~180 N/mm2, and general battery foil can reach the general grade, but high strength, high precision, high surface quality and so on are still only available for mass production by some manufacturers.

Alloy

1060 aluminum foil, 1070 aluminum foil, 1100 aluminum foil, 1235 aluminum foil, 3003 aluminum foil, 8011 aluminum foil, 8079 aluminum foil, etc

Temper

H14,H18, etc

Thickness

Thickness: 0.01mm, 13micron, 15um, 0.018 mm etc

Width: 10mm, 20mm, 30mm, 50mm etc

Surface treatment

Graphene coated, polyurethane laminated, polycoate, poly painted, single bright and other side matt, double sides bright, etc.

Yongsheng Aluminum Foil for Lithium Foil

| Alloy | 1xxx Series: 1050, 1060, 1070, 1100, 1235 |

| 3xxx Series: 3003, 3004 | |

| 5xxx Series: 5052 | |

| 8xxx Series: 8011, 8021, 8079 | |

| Temper | F, O, H14, H16, H18, H19, H22, H24, H26, H28, T etc. |

| Thickness | 0.006-0.2mm. |

| Width | 20mm-1600mm (1.6m). |

| Diameter | Inner Diameter: 76/152 mm; Outer Diameter: Support Customization. |

Good thickness consistency. Free sample.

| Delivery Time | Ready stock 7-10 days, on time delivery guaranteed |

| Loading Port | Qingdao Port, Tianjin Port, Shanghai port. |

| Price Terms | FOB, CIF, CFR, EXW etc. |

| Payment | L/C, T/T, Western Union, etc. |

| Quality Control | Mill Test Certification is supplied with shipment.Third Party Inspection. |

| Certificates | MTC, ISO9001,SGS, ROHS,DNV,TUV,ISO14001,ABS,CCS,CE |

| Standards | ASTM-B209, EN573-1, GB/T3880.1-2006, GB/T 24001-2016, GB/T 19001-2016 |

Yongsheng Aluminum is a raw material manufacturer of aluminum foil (we do not do the later processing such as laminating, printing, gluing, etc., we only provide aluminum foil substrate).

Battery Foil Market Analysis

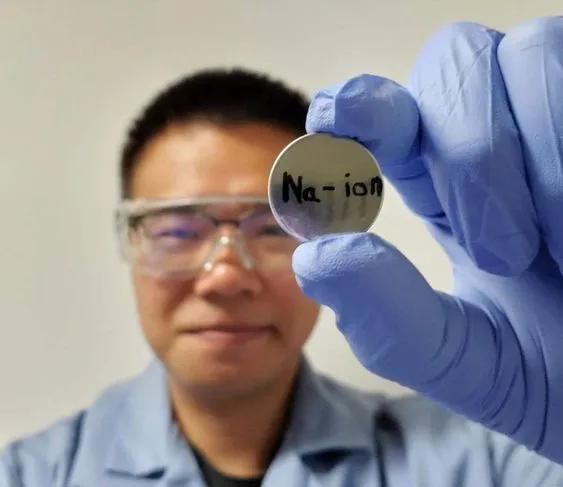

New energy demand continues to exceed expectations, and the demand for battery foil is expected to continue to rise until 2025. Positive collector aluminum foil is used in ternary batteries, lithium iron phosphate batteries, sodium-ion batteries and so on. Therefore, when we measure the demand for battery aluminum foil, we should distinguish between different battery systems.

According to Xin fern lithium data, each GWh ternary batteries need battery foil 300-450 tons, each GWh lithium iron phosphate batteries need battery foil 400-600 tons; and sodium ion batteries, due to the positive pole and negative pole are using aluminum foil, and the negative electrode collector demand for aluminum foil is higher than the positive electrode, so the dosage is higher, each Gwh sodium batteries need aluminum foil 700-1000 tons.

Power battery is the main driving force of the current lithium battery installation, the first half of the new energy vehicle sales exceeded expectations, is one of the few high boom industry under the influence of the epidemic.

Sodium-ion battery commercialization is imminent, will further enhance the demand for battery aluminum foil. The main advantage of sodium-ion batteries is low cost, not subject to resource constraints, with the maturity of related technology and industrial chain, the cost is expected to further decline, is expected to have a better prospect in electric two-wheeled vehicles, low-speed electric vehicles, energy storage, start-stop and other application scenarios.

According to EVTank’s latest estimation, theoretically, the market space of sodium-ion battery can reach 369.5GWh in 2026 with 100% penetration rate; under this assumption, considering that the consumption of aluminum foil for sodium-ion battery is about 800 tons/GWh, the corresponding consumption of aluminum foil for battery in 2025 will reach 295.6 thousand tons.

It is estimated that by 2025, the total global demand for battery aluminum foil will reach 825,000 tons, with a four-year CAGR of 43%. Global battery aluminum foil demand will reach 825,000 tons, with a four-year CAGR growth rate of 43%. Among them, 659,000 tons of power battery, 98,000 tons of energy storage, 69,000 tons of consumer electronics.

Battery aluminum foil quality control requirements are extremely high, such as the requirement of small thickness deviation, generally ± 4% or less, individual battery manufacturers require ± 2% or less; the surface is not allowed to have a diameter of > 1mm pitting, 0.5mm ~ 1mm pitting should be < 3 / m2, the dark side of the bumps, highlights, and so on.