The preparation process of electrode foil is high-purity aluminum → electronic optical foil → corrosion foil → chemical foil, which requires high production and processing technology.

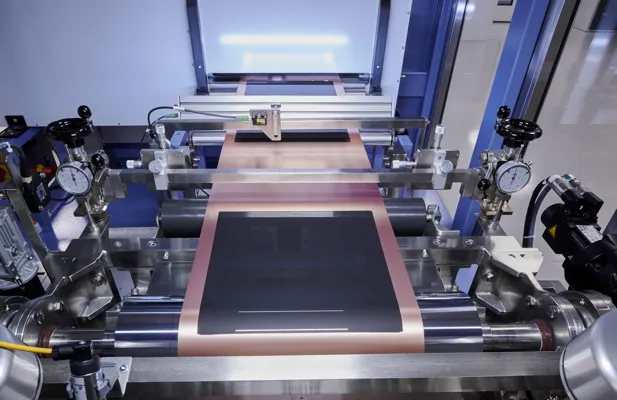

The production of electrode foil mainly utilizes the electrochemical surface expansion corrosion technology, that is, under the condition of energized electricity, the optical foil is corroded with acid chemical agents to form dense microscopic pits, and the corrosion foil is obtained as an intermediate product.

The corrosion foil is then subjected to the chemical formation process, i.e., a voltage is applied to a specific electrolyte, so that when the corrosion foil comes into contact with the specific electrolyte, an oxide film consisting of aluminum oxide is formed on the pits on the surface of the corrosion foil, and the chemical formation foil is obtained.

The oxide film on the surface of the electrodeposited foils increases the capacitor’s electrical storage performance. The etching technology determines the specific capacitance; the higher the specific capacitance, the smaller the area of the electrode foils used and the smaller the size of the capacitor.

According to the classification of operating voltage, low voltage, medium voltage and ultra-high voltage electrode foils are used in different scenarios.

Low-voltage (7.7-170Vf) electrode foils are mainly used in consumer electronics; medium- and high-voltage electrode foils (170-800Vf) are mainly used in energy-saving lamps, industrial control, and inverter technology; ultra-high-voltage (800-1100Vf) electrode foils are used in the production of capacitors with ultra-high voltage requirements, and are usually applied to frequency converters, inverters, communication power supplies, special power storage lines, automatic control of automotive electronics, fueling systems, and automotive equipment.

They are usually used in inverters, inverters, communication power supplies, special power storage circuits, automatic control of automotive electronics, refueling systems, wind power generation, etc.

Electrolytic Capacitors

The downstream market of electrolytic capacitors is mainly used in consumer electronics, industry and communication. The largest downstream application of aluminum electrolytic capacitors is consumer electronics, accounting for 45% of the total, including digital TVs, digital cameras, stereos, smartphones, tablet PCs and so on.

Secondly, they are used in the industrial field, including lighting, industrial control, inverter, etc. The new energy industry generally needs inverter to transmit power to the grid, so aluminum electrolytic capacitors are also widely used in wind power and photovoltaic. In the field of communication, with the advent of 5G era, the density of 5G base stations is higher than 4G base stations, which will also drive the demand for aluminum electrolytic capacitors.

Inverter air conditioners, inverter refrigerators, inverter washing machines, and all kinds of mechanical equipment have inverter demand, and the penetration rate of inverter demand continues to increase. Frequency converters are mainly used in electric motors to change the rotational speed. In the past, electric motors were divided into two kinds: DC motors and AC motors. It is easy to change the speed of DC motors, but rectifiers and brushes must be used, which is very expensive and more difficult to maintain.

AC motors are inexpensive, but the rotational speed is set according to the power frequency, and it is impossible to change the rotational speed. Therefore, people developed inverter to realize the purpose of frequency conversion. Aluminum electrolytic capacitors play a key role in inverters, mainly for filtering.

Yongsheng Aluminum Electrode Foils

Good thickness consistency.

Free samples.

| Alloy | 1xxx Series: 1050, 1060, 1070, 1100, 1235 |

| 3xxx Series: 3003, 3004 | |

| 5xxx Series: 5052 | |

| 8xxx Series: 8011, 8021, 8079 | |

| Temper | F, O, H14, H16, H18, H19, H22, H24, H26, H28, T etc. |

| Thickness | 0.006-0.2mm. |

| Width | 20mm-1600mm (1.6m). |

| Diameter | Inner Diameter: 76/152 mm; Outer Diameter: Support Customization. |

| Delivery Time | Ready stock 7-10 days, on time delivery guaranteed |

| Loading Port | Qingdao Port, Tianjin Port, Shanghai port. |

| Price Terms | FOB, CIF, CFR, EXW etc. |

| Payment | L/C, T/T, Western Union, etc. |

| Quality Control | Mill Test Certification is supplied with shipment.Third Party Inspection. |

| Certificates | MTC, ISO9001,SGS, ROHS,DNV,TUV,ISO14001,ABS,CCS,CE |

| Standards | ASTM-B209, EN573-1, GB/T3880.1-2006, GB/T 24001-2016, GB/T 19001-2016 |

Yongsheng Aluminum is a raw material manufacturer of aluminum foil (we do not do the later processing such as laminating, printing, gluing, etc., we only provide aluminum foil substrate).