1060 Aluminum Strip

1060 aluminum strip is a popular product in the pure aluminum plate and aluminum coil product series. The production technology is relatively mature and the production process is relatively simple. Yongsheng Aluminum was founded in 1999 with a factory area of 380,000 square meters. It specializes in the production of aluminum coil, aluminum sheet, aluminum foil, aluminum strip, aluminum circle, color aluminum, embossed aluminum, mirror aluminum and other products. With 23 years of production experience, our product categories cover 1-8 series alloy grades, it undertakes large-scale project orders, and global annual export volume reaches 300,000 tons.

Product Introduction

1060 aluminum strip is another representative product of the 1000 series aluminum alloy. It is made of pure aluminum plus a small amount of copper elements. It has excellent forming and processing properties, high corrosion resistance, good welding performance and electrical conductivity. Like the 1050 aluminum plate, the 1060 aluminum plate is widely used in products that do not require high strength and is widely used in the field of electronic products, such as batteries, capacitors, etc.

Product Parameters

| Grade | 1060 |

| Temper | O, H12, H14, H16, H18, H19, H24, H26, etc |

| Thickness | 0.1mm-6.5mm |

| Width | 3mm-2600mm |

| Size | Size can be produced as per clients requirement |

| Delivery Time | Ready stock 7-10 days |

| MOQ | 1 ton |

| Loading Port | Qingdao Port, Tianjin Port, Shanghai port. |

| Price Terms | FOB, CIF, CFR, CNF, etc. |

| Quality Control | Mill Test Certification is supplied with shipment. Third Party Inspection is acceptable. |

Product Properties

Chemical Composition:

| Element | Composition (%) |

| Aluminum (Al) | ≥ 99.6% |

| Iron (Fe) | ≤ 0.35% |

| Silicon (Si) | ≤ 0.25% |

| Copper (Cu) | ≤ 0.05% |

| Manganese (Mn) | ≤ 0.03% |

| Magnesium (Mg) | ≤ 0.03% |

| Zinc (Zn) | ≤ 0.05% |

| Others | ≤ 0.15% |

Mechanical Properties:

|

Alloy |

Temper | Thickness (mm) | Tensile Strength (Mpa) | Yield Strength (MPa) | Elongation (%) |

Hardness (HV) |

|

1060 |

0 |

>0.2-0.5 | 60-100 | ≥15 | ≥20 | 20-30 |

|

>0.5-1.0 |

≥30 |

|||||

| >1.0-4.0 |

≥35 |

|||||

|

H12/H22 |

>0.2-0.5 | 80-120 | ≥60 | ≥12 | 30-40 | |

|

>0.5-1.0 |

≥15 |

|||||

| >1.0-4.0 |

≥18 |

|||||

|

H14/H24 |

>0.2-0.5 | 95-135 | ≥70 | ≥6 | 35-45 | |

|

>0.5-1.0 |

≥8 |

|||||

| >1.0-4.0 |

≥10 |

|||||

|

H16/H26 |

>0.2-0.5 | 110-155 | ≥75 | ≥2 | 43-55 | |

|

>0.5-1.0 |

≥4 |

|||||

| >1.0-4.0 |

≥6 |

|||||

|

H18/H28 |

>0.2-0.5 | ≥125 | ≥85 | ≥2 | 50-65 | |

|

>0.5-1.0 |

≥3 |

|||||

| >1.0-4.0 |

≥4 |

Physical Properties:

| Physical Properties | Value |

| Density | 2.70 g/cm³ |

| Melting Point | 660.3 °C |

| Thermal Expansion | 23.5 x 10^(-6)/°C |

| Modulus Of Elasticity | 69 GPa |

| Thermal Conductivity | 237 W/(m·K) |

| Resistivity | 0.0282 μΩ·m |

Product Applications

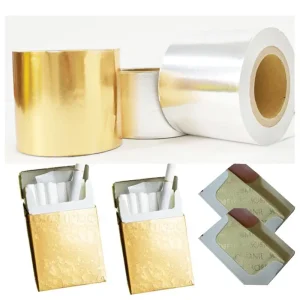

1060 aluminum strip is widely used in electronics, chemical industry, construction, aviation and other fields, including the manufacture of wires, cables, transformers, engine parts, decorative materials, etc. In the electronics industry, 1060 aluminum strips can be used to make LED light strips, electronic components, PCBs, etc.; in the construction industry, 1060 aluminum strips can be used to make doors, windows, curtain walls, roofs, etc.

Product Advantages

- High plastic deformation, excellent molding and manufacturing characteristics, high corrosion resistance, and good conductivity and heat transfer.

- Green. Long service life and low direct costs.

- The production technology is perfect and the price is favorable.

- Low density, lightweight and convenient.

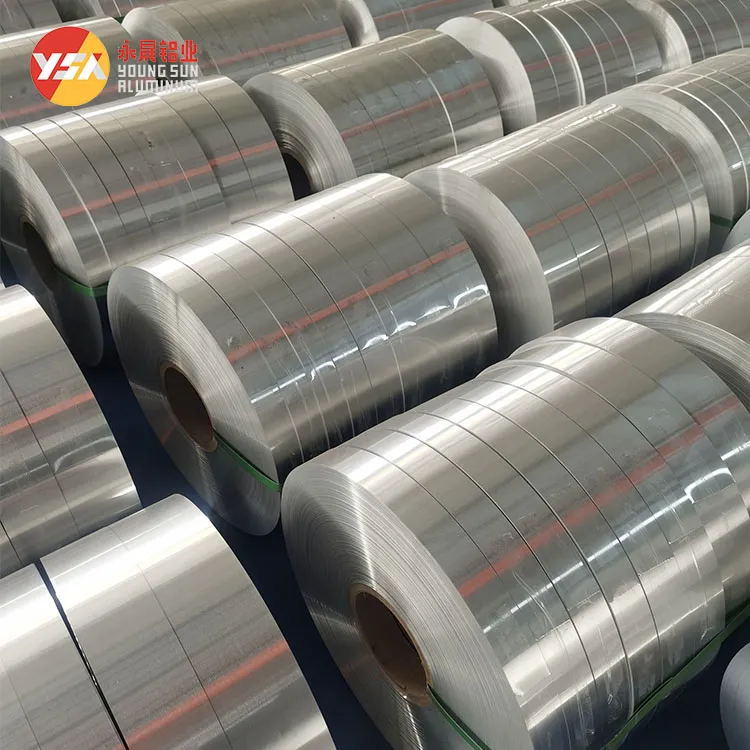

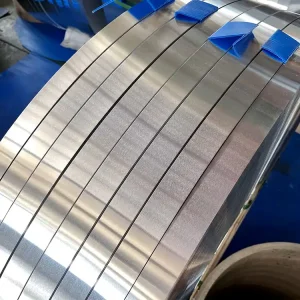

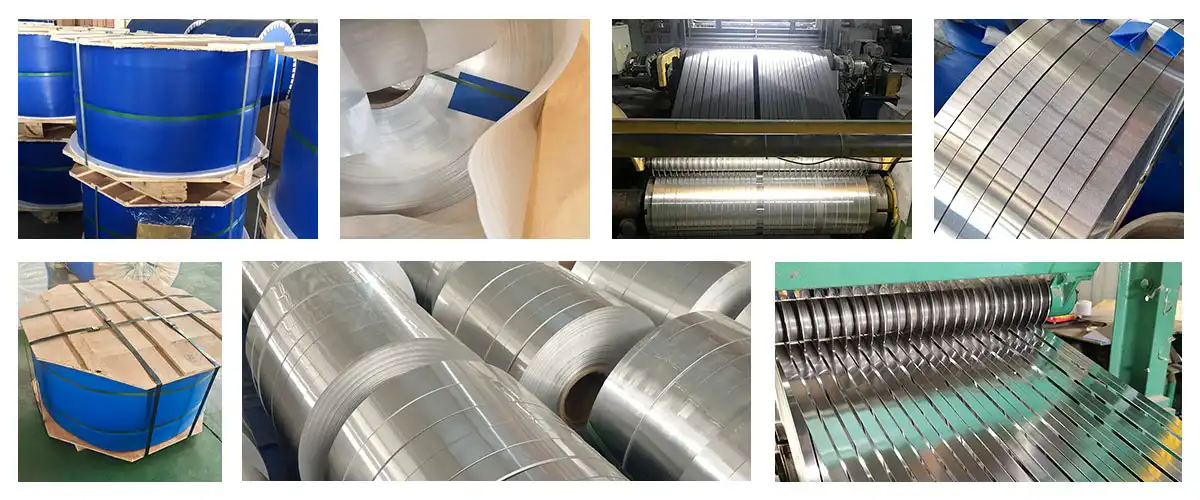

Product & Packaging Photos

Why Choose Us

Yongsheng Aluminum is a leading aluminum products manufacturer&supplier in China with 25 years of export experience. Our outstanding product quality, price, and always on-time delivery has won us many long term partners and gained a great reputation worldwide. We provide one-stop product solution for both CC&DC aluminum products.

Contact us to get your quotation.

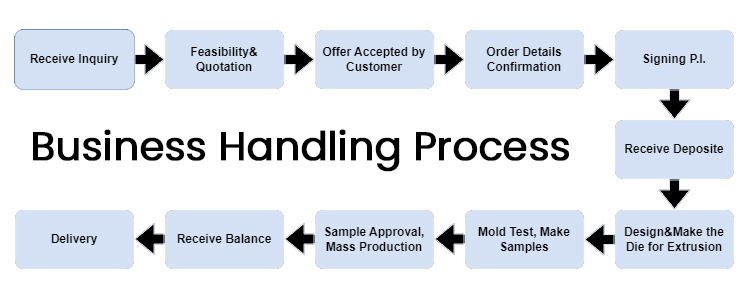

Business Handling Processes