Aluminum Coil For Insulation

Aluminum coil for insulation is a crucial element in many industrial and construction applications where corrosion resistance and thermal insulation are critical. Although there are many variations of these adaptable materials, the 1060 insulation aluminum coil and the 3003 insulation aluminum alloy coil are the two most used types. Henan Yongsheng Aluminum produces aluminum coil for insulation in high quality. To enhance competitiveness, our factory continuously incorporates state-of-the-art machinery and technology. Our fleet comprises 20 casting production lines, 2 color-coated aluminum coil production lines, 3 slitting production lines, 4 shearing production lines, 32 punching machines, 10 CNC lathes, and 4 embossed aluminum production lines. Notably, over 40% of our fleet is exported, contributing to an annual output of 300,000 tons or higher. Welcome to visit our factory!

Product Introduction

Aluminum coil for insulation describes a particular kind of aluminum coil that is intended exclusively for use as insulation in the building sector. Aluminum coil for insulation is made up of an endless roll of aluminum sheets that is used to enclose thermal insulation materials in protective layers or barriers. In addition to acting as a protective layer, aluminum coils include vapor barrier qualities, moisture resistance, and increased longevity for insulation systems.

Specifications

| Alloy | 1060, 3003 |

| Temper | soft HO (h0), H14, etc |

| Thickness(mm) | 0.3mm – 3.0mm |

| Width(mm) | 600mm – 2000mm |

| Surface treatment | embossed stucco, color coated, reflective polished mirror, etc |

| MOQ | 1 Tons |

| Delivery | Ready stock: 7-10 days, future goods: 15-30 days |

| Price term | EXW,FOB,CIF,CFR,CNF,etc. |

| Payment | L/C,T/T,Western Union,etc. |

| Certificates | ISO9001&GS&ROHS&FDA&TUV&ISO&GL&BV,etc. |

Product Application

- Sound Insulation Aluminum Coil: Sound insulation aluminum coils are specially engineered to decrease the propagation of sound waves and establish a more tranquil atmosphere. Crafted from top-notch aluminum materials, they possess exceptional acoustic properties and find application across various industries for noise management. These coils effectively diminish unwelcome noise, enhancing comfort and productivity in diverse environments.

- Thermal Insulation Aluminum Coil: Thermal insulation aluminum coils are specifically engineered to enhance energy efficiency by reducing heat transfer. Constructed from premium aluminum materials, these coils possess exceptional thermal insulation properties. They are extensively utilized in diverse industries and applications that require effective heat insulation, including HVAC systems and construction projects. By incorporating thermal insulation aluminum coils, the loss or gain of heat can be significantly minimized, leading to improved energy conservation and creating comfortable environments in both residential and commercial settings.

- Aluminum Coil for Insulated Pipe: Aluminum coil for insulated pipe finds frequent use in both industrial and building sectors, and they must has specific characteristics such as low thermal conductivity, low density, high flexibility, as well as resistance to fire and water. Aluminum alloy materials are commonly used in the producing of insulation materials for pipes, specially in chemical enterprises. The typical materials used include 1060 aluminum strips for insulation, 3003 aluminum strips for insulation, and 3104 aluminum coils for insulation. Although 3105 aluminum coils for insulation are less commonly used, they can still be used effectively for thermal insulation in pipelines.

- Aluminum Coil for Equipment Insulation: Thermal insulation and energy conservation play a crucial role in both industrial production and daily life. Various industries, including the iron and steel industry, chemical industry, petroleum sector, and electric power industry, require thermal insulation measures for pipes and equipment. Typically, metal plates made of materials such as iron sheets and aluminum coils for equipment thermal insulation. Due to the excellent corrosion resistance offered by aluminum materials, they are more extensively utilized in this context.

- Aluminum Coil for Building Insulation: Aluminum coil for building insulation offers a range of colors, an appealing appearance, and a notable decorative effect. As a novel type of thermal insulation material, the 3003 aluminum coil is frequently utilized as part of the aluminum-manganese alloy series. Thanks to the inclusion of manganese, this material boasts excellent rust resistance, earning it the name of “rust-proof aluminum coil.” Its corrosion resistance surpasses that of pure aluminum from Series 1, making it suitable for various specialized environments. In the realm of building engineering, 3003 metal building insulation coils assume a prominent position.

- Roof and Wall Insulation: Aluminum insulation coil is used in roofing and wall systems to improve thermal insulation and energy efficiency. It acts as a reflective barrier, reducing heat gain in summer and heat loss in winter, thereby enhancing indoor comfort and reducing energy costs.

- Refrigeration and Cold Storage Insulation: Aluminum insulation coil is applied in refrigeration units, walk-in coolers, and cold storage facilities to insulate walls and ceilings. It helps maintain the desired low temperatures, prevents condensation, and improves energy efficiency in refrigeration systems.

- Fire Protection: Aluminum insulation coil can be utilized in fire protection systems. It is used as a protective covering around fire-resistant materials to enhance their performance and prevent the spread of fire, providing an additional layer of safety.

- Automotive Insulation: Aluminum insulation coil finds applications in the automotive industry for insulating various components, such as engine compartments, exhaust systems, and heat shields. It helps reduce heat transfer, dampens noise, and improves overall vehicle performance and comfort.

Product Advantages

- Fire Resistance: Aluminum insulation coil exhibits excellent fire resistance properties. It has a high melting point and does not contribute to the spread of flames. As a result, it enhances fire safety and can be used in fire protection systems.

- Thermal Insulation: Aluminum insulation coil effectively reduces heat transfer, providing excellent thermal insulation properties. It helps to maintain desired temperatures, whether for heating or cooling purposes, leading to energy savings and increased comfort in buildings or systems.

- Reflectivity: Aluminum has high reflectivity, meaning it reflects radiant heat. When used as insulation, aluminum insulation coil helps to reflect heat away from the insulated area, reducing heat absorption and minimizing temperature fluctuations.

Product & Packaging Photos

Why Choose Us

Yongsheng Aluminum is a leading aluminum products manufacturer&supplier in China with 25 years of export experience. Our outstanding product quality, price, and always on-time delivery has won us many long term partners and gained a great reputation worldwide. We provide one-stop product solution for both CC&DC aluminum products.

Contact us to get your quotation.

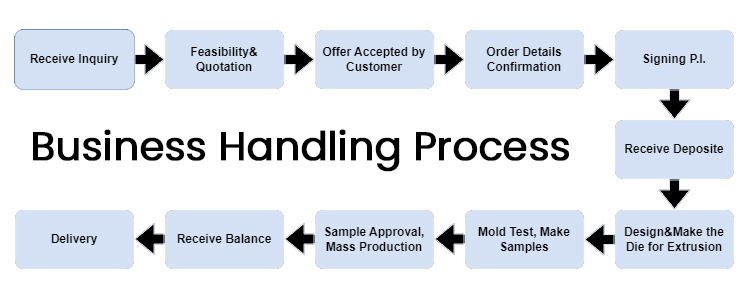

Business Handling Processes