Aluminum Foil Coil for Food Packaging

Aluminum foil coil for food packaging serves as a versatile and essential material in the food industry. Henan Yongsheng Aluminum Co., Ltd. produces high-quality and safe aluminum foil coil for food packaging. We are situated in Gongyi City, Henan Province, which is known for its industrial cluster. With 25 years of expertise, Yongsheng is a manufacturing facility specializing in aluminum sheet, coil, foil, and strip. Spanning across an expansive area of 300,000 square meters, our factory accommodates a workforce of 3,200 dedicated employees.

Product Introduction

Aluminum foil coil, due to its ability to allow the migration of moisture, oxygen, other gases, volatile aromas, and the impact of light, generally surpasses any plastic material in these aspects. As a result, aluminum foil coil holds significant importance in laminates and finds extensive use in food packaging.

Specifications

| Alloy | 8011/3003 |

| Width | H O |

| Thickness | 0.03mm – 0.15mm |

| Width | Customized |

| MOQ | 1 ton |

| Price term | EXW,FOB,CIF,CFR,CNF,etc. |

| Payment | L/C,T/T,Western Union,etc. |

| Certificates | ISO9001&GS&ROHS&FDA&TUV&ISO&GL&BV,etc. |

Product Application

Aluminum foil coil for food packaging is produced by cold-rolling or hot-rolling, resulting in aluminum foil mother rolls that possess a consistent thickness, smooth surface, absence of pinholes, dust particles, and odor. Aluminum foil coil for food packaging is commonly used in the packaging of aviation food and cake products for retail purposes. They boast a rapid turnover rate and are consumed in large quantities, making them well-suited for batch sales.

Product Advantages

One of the notable advantages of aluminum foil coil for food packaging is its superior barrier properties. Aluminum foil coil for food packaging exhibits high resistance to the migration of moisture, oxygen, and other gases, as well as volatile aromas and the influence of light. This exceptional barrier performance surpasses that of most plastic materials, making aluminum foil a preferred choice for preserving the freshness and quality of various food products.

The versatility of aluminum foil coil enables its application in a wide range of food packaging solutions. It is commonly used in laminates, where it is combined with other materials to enhance barrier properties and provide additional functionalities. This allows for customized packaging designs tailored to meet specific requirements such as moisture resistance, heat insulation, and extended shelf life.

Product Process

- Raw materials: Raw materials are carefully chosen to meet the standards and requirements for food packaging, ensuring their high quality. These materials undergo screening and testing to confirm their non-hazardous nature.

- Cold or hot rolling processes: Aluminum foil coils are produced using either cold or hot rolling techniques, resulting in a uniform thickness and smooth surface. These processes eliminate defects such as pinholes, dust particles, and odors from the foil’s surface.

- Clean environment: The production environment is strictly maintained in terms of cleanliness to prevent any contamination from entering the aluminum foil coils. This emphasis on cleanliness contributes to the hygiene and safety of the aluminum foil.

- Quality control: Stringent quality control measures are implemented throughout the production process, including thorough inspections and testing. These measures guarantee compliance with international standards for food packaging. Specifically, they ensure that the aluminum foil rolls are free from hazardous substances and do not pose any risk of harmful migration.

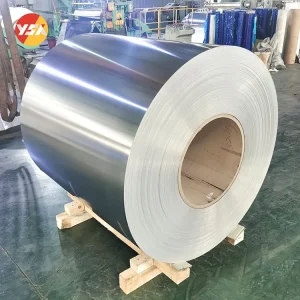

Product & Packaging Photos

Why Choose Us

Yongsheng Aluminum is a leading aluminum products manufacturer&supplier in China with 25 years of export experience. Our outstanding product quality, price, and always on-time delivery has won us many long term partners and gained a great reputation worldwide. We provide one-stop product solution for both CC&DC aluminum products.

Contact us to get your quotation.

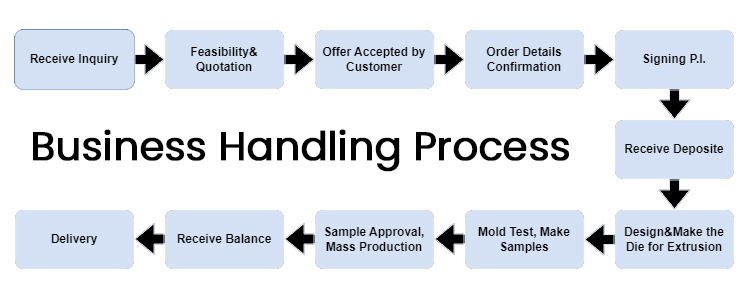

Business Handling Processes