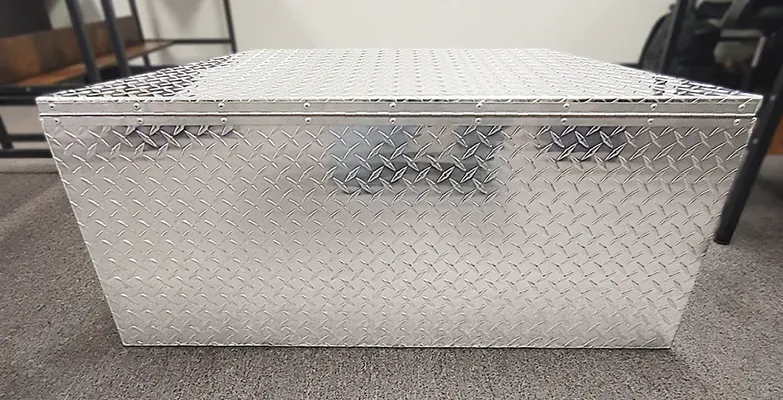

Aluminium tool boxes are tool storage and protection devices that are specifically developed for use on trucks. They are often built of several types of aluminum alloy materials and have the advantages of a beautiful look, light weight, and a robust load-bearing ability. The outer shell of this aluminum tool chest is strong and durable, able to withstand hard working environments and vibrations, ensuring the safety of tools during transportation and use.

The lightweight aluminum storage boxes can be mounted on pickup trucks, trailers, pump trucks, and other vehicles to store a wide range of tools such as loading and unloading tool boards, jacks, wrenches, crowbars, and even vacation and camping items.

Advantages of Aluminium Tool Box For Trailers:

- High strength.

- Anti-corrosion.

- High quality and durable.

- Lightweight.

- Easy to clean.

- Strong safety performance.

- Seal design.

Aluminium Truck Tool Box Categories:

Crossover tool box: The crossover tool box is usually positioned at the head of the truck bed and extends across the whole width of the bed. They’re made to fully utilize the truck bed’s breadth without getting in the way of using it. Wide-capacity crossover tool boxes are ideal for holding greater volumes of tools and equipment.

Side-mount tool box: Typically mounted on the side of the truck bed, usually between the driver and passenger doors or next to the rear wheels. Their location makes the toolbox easily accessible without having to climb into the truck bed. This type of tool box is suitable for situations where tools need to be used frequently, such as couriers or maintenance workers.

Aluminum underbody tool box: It usually installed on the truck bed frame, this tool box is situated at the bottom of the truck bed. For professionals that need to store large or heavy tools, like mechanics and construction workers, aluminum underbody tool bins offer extra storage space. Additionally, you may get to them from both sides.

Aluminum trailer tongue box: An aluminum trailer tongue box, also known as a trailer tongue storage box or simply a tongue box, is a specialized storage container designed to be mounted on a trailer tongue. Specially used to store various tools, equipment, etc.

Trailer topsider tool box: It usually used to carry and store the trailer’s necessary equipment and accessories, this tool box fits well in the front section of the trailer. For trailers that are being driven on the road, they are typically smaller.

Overhead tool box: An overhead tool box is installed above the truck body, typically on the top or side edge. They increase storage capacity without interfering with using the truck bed. Light tools and supplies are frequently kept in these tool boxes.

What Type Of Aluminum Are Truck Tool Boxes Made From?

Aluminium tool boxes for caravans can be made of different series of aluminum alloys, generally 1060, 1070, 3003, 5052, 6061, etc. Among them, 5052 aluminum alloy has the highest strength, and the thickness of aluminum tool boxes is generally 1.5mm-3.0mm. Smaller tool boxes will use thinner aluminum sheets, while larger tool boxes will require thicker aluminum sheets for strength and durability. Usually, the surface of the truck box is mainly made of diamond plate tool box, especially black diamond plate tool box. The main embossed form is: 3-bar aluminum checker plate or 5-bar aluminum checker plate.

1060 aluminum truck tool box: This material is commonly used in the production of light trucks such as light trucks, vans, pickup trucks, and so on.

1070 aluminum truck tool box: Suitable for making truck tool boxes that demand more strength and durability, such as big trucks, flatbed trucks, commercial vehicles carrying heavier weights, and so on.

3003 aluminum tool box: Commonly used in the manufacture of medium-sized trucks such as medium-sized trucks, box trucks and other medium-load commercial vehicles may use 3003 aluminum alloy truck tool boxes.

5052 aluminum tool box: 5052 aluminum alloy is often used to manufacture truck tool boxes such as large trucks, trailers, professional commercial vehicles, etc.

6061 aluminum tool box: Suitable for manufacturing truck tool boxes such as heavy-duty trucks, transport vehicles, etc.

Considerations When Choosing An Aluminum Truck Tool Box:

- Types of Tools and Equipment: First, determine the tools and equipment you will need to keep and transport. Different types and sizes of tool boxes are appropriate for different types of tools, so make sure your tool box is large enough to hold your equipment.

- Truck type and size: Consider the type and size of your truck to make sure the tool box you choose will fit your truck. Different types of trucks (e.g. pickup trucks, vans, trailers) may require different types of tool boxes.

- Tool Box Types: Discover the various kinds of tool boxes, such as side-mount, bottom-mount, trailer-mounted, overhead, and cross-mount models. Select the kind based on what you require.

- Size and Capacity: Ascertain the dimensions and holding power of the required toolbox. If your tool box isn’t big enough, think about how much tools and equipment you usually need to carry.

- Customisation options: Consider whether you need customisation options within your toolbox, such as shelves, dividers, drawers and compartments, to better organise and protect your tools.

- Durability: Consider the tool box’s durability aspects, such as materials and build quality. Aluminum tool boxes are well-known for their durability, but make certain that they are appropriate for your needs.

- Price Range: Choose a toolbox within the appropriate price range based on your budget. The prices of toolboxes of different brands and models vary greatly.

- Brand and Manufacturer: Choose a well-known brand and reliable manufacturer to ensure tool box quality and after-sales service.

- Customer Reviews: Check out toolbox reviews and feedback from other users to get a feel for real-world experience and performance.

- Appearance: Finally, you might also consider the appearance and color of your tool box to match the exterior of your truck.

How to Clean Aluminum Tool Boxes

To clean your aluminum truck tool box, you can follow these steps:

- Empty the tool box: Remove all tools and items from the tool box and remove it completely from the vehicle. Use a hose or a bucket of water to rinse away any loose dirt or debris from the surface of the tool box. Clean or soapy water will do. .

- Prepare a cleaning solution: Use a specialty cleaner or a regular cleaner to break down stuck-on dirt, and simply wipe with a microfiber towel after applying the cleaner.

- Polishing Job: If you feel like the cleaning isn’t up to your high standards, I recommend using a polisher or sander with a fleece attached. When polishing, turn the wool pad sideways to easily access the grooves of the aluminum diamond tool box.

- Polishing: After polishing, there will be more black stains on the outside of the tool box. You need to use a multi-purpose cleaner, soapy water or clean water to clean it, and then wipe it with a microfiber towel.

- Reassemble and organize: Once the tool box is dry, you can reassemble and organize the tools and items inside.