What is Aluminum Curtain Wall?

Aluminum curtain walls mainly use 1000, 3000, 5000, and 6000 series aluminum sheets, which are mostly hung in the form of plates on the exterior walls of the main structure. The curtain walls are not load-bearing, but must withstand wind loads. The common thicknesses of aluminum curtain walls are 1.5mm, 2.0mm, 2.5mm, 3.0mm, and the alloy is 3003 H24 aluminum sheet.

What Are The Components Of Aluminum Curtain Wall?

The aluminum curtain wall structure is mainly composed of embedded panels, panels, reinforcing ribs and corner codes. The embedded plate is connected to the structure through bolts and is stressed. The corner codes can be directly bent and stamped from the panel, or they can be riveted on the small side of the panel. The reinforcing ribs are connected to the electric welding screws behind the panel (the screws are directly welded on the back of the panel), making it a solid whole, which greatly enhances the strength and rigidity of the aluminum veneer curtain wall and ensures smoothness during long-term use. strength and wind and earthquake resistance. If sound insulation and insulation are required, efficient sound insulation and insulation materials can be installed on the inside of the aluminum sheet.

Structure Of Aluminum Sheet Curtain Wall:

Aluminum sheet curtain walls can be divided into two types according to their structural forms: unit aluminum sheet curtain walls and component aluminum sheet curtain walls. Unit curtain wall refers to a framed curtain wall in which panels, beams, and columns are assembled into curtain wall units in the factory and installed and constructed on site in the form of curtain wall units. A modular curtain wall is a framed curtain wall in which columns, beams and panels are installed sequentially on site.

How To Classify Aluminum Curtain Walls?

Name | Category | Details | Picture |

Honeycomb Aluminum Panel | _ | “Honeycomb aluminum panel” is the earlier used aluminum sheet curtain wall. It is a honeycomb made of aluminum foil sandwiched between two layers of aluminum sheets with a thickness of 0.8~1.8 mm. The total thickness generally ranges from 6 to 25.4 mm. It is characterized by a flat surface and good rigidity. The size of the honeycomb aluminum curtain wall can be made large and can remain flat. |  |

Single Layer Aluminum Plate | Single layer integral stamped aluminum sheet | “Single-layer integral stamped aluminum sheet” is made of a single-layer aluminum sheet through stamping technology. It can be regarded as a special case of single-layer aluminum plate. |  |

Composite aluminum sheet | “Composite aluminum sheet” is made of two layers of thin aluminum sheets sandwiched between polyethylene plastic sheets. Since the surface aluminum sheet is thin, the roller coating method can be used when applying the weather-resistant finishing paint on the surface, making the color of the aluminum sheet plate facing very special. Uniform and no color difference. In addition, it is light in weight, has good surface flatness, and has excellent cutting and bending processability. It is especially suitable for on-site processing and production, and can better adapt to the complex and changeable shapes of buildings. |  |

Advantages Of Aluminum Curtain Wall:

- It resists corrosion well, is light in weight, stiff, and strong. Up to 25 years pass without any discoloration in the fluorocarbon paint.

- Good craftsmanship. Using the process of first processing and then spray painting, the aluminum plate can be processed into various complex geometric shapes such as plane, arc and spherical surfaces.

- It is not easily stained and is simple to clean and maintain. The fluorine paint film’s non-adhesive nature makes it impossible for impurities to cling to the surface and maintains good cleanliness.

- Installation and construction are convenient and quick. The aluminum sheets are formed in the factory and do not need to be cut at the construction site and can simply be fixed.

- It can be recycled and reused, which is environmentally friendly.

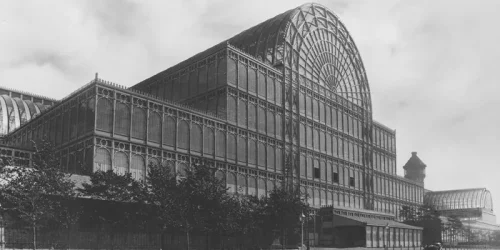

Development History Of Curtain Wall

At the London Industrial Exposition in 1851, the Crystal Palace was the first structure to incorporate glass curtain walls. It concentrated on issues such as leakage prevention, acoustic insulation, thermal insulation, and the aging of silicone structural sealant materials. This was the first generation of curtain walls.

In 1917, the Halliday Building in San Francisco, California, had its debut. It is the most important architectural flashpoint in San Francisco, representing the birth of the glass curtain wall industry. It is the first glass curtain wall built in the United States.

The Empire State Building in New York, USA, built in 1931, is 384m high. Its exterior wall is made of stainless steel and aluminum profiles as the skeleton and granite and stainless steel plates as the surface materials. It already has the preliminary characteristics of a curtain wall.

In the early 1950s, the Lever Building in New York and the United Nations Building in New York used glass, aluminum alloy, and steel, which were considered architectural symbols of modern high-tech development.

Aluminum Curtain Wall vs. Storefront

- The main purpose of aluminum curtain wall is to protect interior spaces from weather elements, provide thermal insulation, and enhance the visual appearance of a building. The storefront is mainly used as the entrance and display area of commercial institutions. Usually installed on the ground, suitable for single-story or low-rise buildings.

- The aluminum sheet for curtain wall is designed to be lightweight and non-load-bearing. They use an aluminum frame combined with a variety of filling materials. Storefronts usually consist of aluminum frames with large glass areas.

- Aluminium curtain walls are designed for large buildings, and the panels can be modular or continuous. Storefronts are typically used in smaller commercial buildings and are often custom designed to meet the specific needs of the business.