Overview

Aluminum alloy is mainly embodied in consumer electronic products in the form of shells, frames, heat sinks and aluminum tubes. Among them, 5000 series and 6000 series are the most adopted aluminum alloy series. 7000-series aluminum alloys are mainly imported, and only a few companies such as Apple adopt them in high-end products. At present, the following alloy series are mainly used:

5000 series (mainly magnesium) The main element of this series of aluminum plate is magnesium, containing magnesium between 3-5%. Can also be called aluminum-magnesium alloy. The main features are low density, high tensile strength and high elongation. Widely used in conventional industry. Processing technology for continuous casting and rolling, belongs to the hot rolled aluminum plate series can do oxidation deep processing. In our country 5000 series aluminum plate belongs to one of the more mature aluminum plate series.

6000 series (mainly magnesium and silicon) mainly contains magnesium and silicon two elements, is a cold treatment of aluminum forging products, suitable for anti-corrosive, oxidation requirements of high application. Good usability, excellent interface characteristics, easy coating, good workability.

7000 series (mainly zinc) mainly contains zinc elements, is aluminum-magnesium-zinc-copper alloy, is a heat-treatable alloy, belongs to the super-hard aluminum alloy, has good wear resistance. The main feature is hardness, it requires high strength, corrosion resistance of high stress structural parts, mold manufacturing.

To enhance the resistance to corrosion, the aluminum alloy casing of cell phones undergoes artificial anodic oxidation, which not only improves the appearance but also enhances the surface hardness. The quality and adhesion of the anodic oxide film directly impact the visual appeal and corrosion resistance of the cell phone. In the case of 7 series aluminum alloy, the high alloy composition makes it challenging to achieve uniform distribution during conventional melting and casting of aluminum rods. This non-uniformity in distribution leads to the occurrence of macro-partialization, also known as bias polymerization. Although some of the segregation can be partially improved during subsequent processes like homogenization treatment and extrusion of aluminum rods, it cannot be completely eliminated. The presence of segregation means that the composition of different parts of the material is not uniformly distributed. This non-uniform composition results in variations in the quality and adhesion of the anodic oxide film. Consequently, issues such as color differences and other appearance defects may arise after oxidation, affecting the stability of performance. Moreover, inadequate adhesion of the oxide film at certain positions can lead to its detachment. Once the protective oxide film is lost, corrosion can be accelerated by factors like hand sweat, humid air, and hot weather. As science and technology advance, computers have become integral to people’s lives, entertainment, work, and office environments. Similarly, aluminum, being one of the most abundant metals on Earth, is extensively used in computer mainframes, keyboards, mice, mouse pads, and other components. This preference for aluminum alloy is primarily driven by its excellent heat dissipation properties and the ease of surface treatment.

Specific Applications

Computer

Aluminum plays a crucial role in the construction of computer components. Within the computer, various metals are utilized to enable different functions to operate smoothly and efficiently. Specifically, aluminum is employed in the creation of heat sinks. These heat sinks are designed to absorb and dissipate the heat generated by the computer, protecting other vital components from excessive heat exposure.

Power lines

Aluminum finds extensive use in electrical applications, particularly in power lines. Power lines have long served as the primary means of transmitting electricity over long distances. Since its introduction in the early 20th century, aluminum has been widely employed in the construction of power lines. Compared to materials like copper, aluminum offers the advantage of being lighter in weight. While aluminum may not possess the same level of electrical conductivity as copper, it offers greater flexibility due to its ductility, making it easier to manufacture power lines. Additionally, aluminum exhibits resistance to various forms of corrosion, enabling it to withstand the harsh conditions to which power lines are exposed. As power lines continue to be a ubiquitous feature of our infrastructure, aluminum will continue to play a pivotal role in the global power supply.

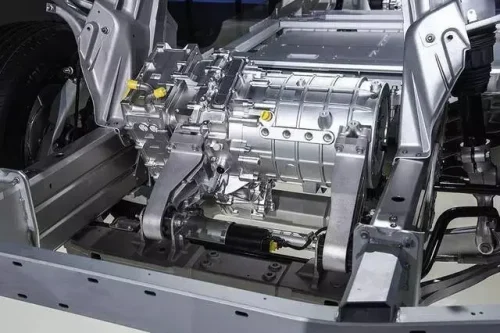

Electric Motors

Electric motors, which are responsible for various mechanical movements in different applications, also incorporate aluminum in their construction. These motors are found in a range of sizes and are utilized across industries such as manufacturing, automotive, and aerospace. While conventional motors rely on fuel for power, electric motors can operate on batteries, rendering them portable and easier to manufacture. Aluminum is predominantly used in the motor’s structure, providing a lightweight and durable framework that can withstand high temperatures and extreme conditions.

Power Systems

In addition to its use in power lines, aluminum is a key metal employed in power grids and other power systems. The conductivity of aluminum enables efficient and rapid energy distribution. One of the factors driving the adoption of aluminum in power systems is its cost-effectiveness in manufacturing. While copper exhibits excellent electrical conductivity, its production costs can pose challenges for various manufacturing companies. Aluminum strikes a favorable balance between electrical conductivity and cost, making it an ideal material for a wide range of electrical devices.

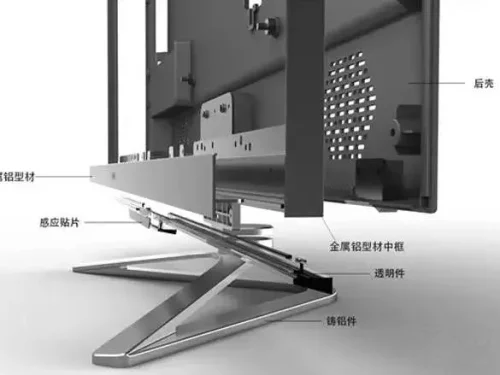

Enclosures and Casings

The fabrication of enclosures and casings for electronic devices commonly uses aluminum. It’s a fantastic material to use when creating sturdy and aesthetically pleasing enclosures for electronic devices like laptops, tablets, smartphones, and other devices owing to its lightweight design and corrosion resistance.

Summary

Aluminum, owing to its distinctive characteristics and benefits, is an indispensable material in the electronics industry. Enclosures and heat sinks of electronic devices often utilize aluminum, offering them with qualities such as durability, reliability, and lightweight design. As the industry continues to evolve, aluminum is projected to play an even fantastic role in shaping the future advancements of electronics.