What is Aluminum Diamond Checker Plate Coil?

The diamond checker plate pattern is a series of raised diamonds or lines embossed onto the surface of the aluminum coil. This pattern not only enhances the visual appeal but also provides excellent traction and slip resistance in various environments.

Manufacturing Process

To begin, it is crucial to fabricate a mold that matches the desired diamond or line pattern precisely. This mold is typically constructed from metal, like steel or carbide, and its design ensures the accuracy and quality of the embossing effect.

Next, the aluminum coils are prepared. These coils can be either hot or cold rolled products. Depending on the required specifications, the appropriate aluminum alloy material is chosen and cut into the appropriate size and shape to align with the mold.

Before embossing, the aluminum coils are subjected to a heating process. This step increases the malleability of the aluminum material, facilitating the embossing operation. The temperature of the aluminum coil is raised adequately during heating to allow for the subsequent embossing step.

The embossing process involves placing the heated aluminum coil into the mold and applying pressure to bring it into contact with the mold surface. The diamond or line pattern on the mold creates raised impressions on the surface of the aluminum coil. Specialized embossing machinery or hydraulic presses are typically used to exert sufficient pressure, ensuring the complete transfer of the pattern onto the surface of the aluminum coil.

After embossing, the aluminum coils are cooled to stabilize their shape and structure. This can be accomplished through natural cooling or by using cooling equipment. Once the cooling process is complete, additional treatments such as cleaning and surface coating may be applied to enhance the appearance and corrosion resistance of the aluminum coils.

Applications

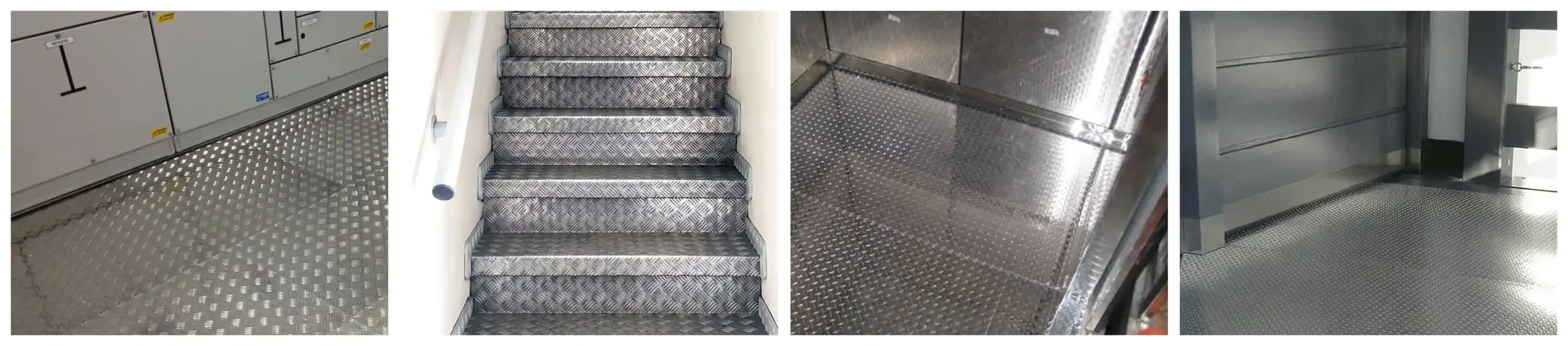

Flooring and stair treads in industrial and commercial settings: Aluminum diamond checker plate roll is extensively used for flooring and stair treads in industrial and commercial environments. Its slip-resistant surface enhances safety, while its durability stands heavy foot traffic, abrasion, andwear. Industries such as manufacturing plants, warehouses, airports, and hospitals benefit from its reliable performance in high-traffic areas.

Vehicle flooring and protective lining in transportation industries: Aluminum diamond plate coil is an fantastic choice for vehicle flooring and protective lining in transportation industries. Its slip-resistant and durable surface provides a secure platform for vehicles, preventing cargo or equipment from shifting during transportation. It also protects the vehicle’s interior from damage caused by heavy loads.

Decorative and functional applications in architecture and interior design: The unique diamond checker plate pattern of the coil lends itself to decorative and functional applications in architecture and interior design. It adds a visually appealing element to spaces, creating a modern and industrial aesthetic. Aluminum diamond checker plate coil can be used as wall panels, ceilings, decorative cladding, or even furniture, offering a blend of style and functionality.

Other specialized uses such as toolboxes, truck beds, and trailer walls: Aluminum diamond plate coil finds specialized applications in toolboxes, truck beds, and trailer walls. Its strength, durability, and corrosion resistance make it well-suited for these demanding environments. It protects the contents of toolboxes, prevents damage to truck beds caused by heavy loads, and ensures the longevity of trailer walls despite exposure to various weather conditions.

Features

Durability and strength: Diamond plate aluminum coil exhibits exceptional durability and strength, making it suitable for demanding applications. It can withstand heavy loads, resist impact and deformation, and maintain its structural integrity over time.

Slip resistance and safety advantages in various applications: The diamond checker plate pattern on the surface of the coil provides excellent slip resistance, even in wet or slippery conditions. This makes it an ideal choice for environments where safety is paramount, such as industrial facilities, commercial buildings, and transportation vehicles.

Corrosion resistance and suitability for outdoor use: Aluminum diamond checker plate coil is highly resistant to corrosion, making it suitable for outdoor applications. It withstands exposure to moisture, UV rays, and other environmental elements without rusting or deteriorating, ensuring long-lasting performance.

Lightweight properties and ease of installation: Despite its strength, aluminum diamond checker plate coil is remarkably lightweight. This lightweight nature makes it easier to handle, transport, and install compared to alternative materials. It reduces the load on supporting structures and simplifies installation processes, saving time and labor costs.

Versatility and customization options: Aluminum diamond checker plate coil is available in various sizes, thicknesses, and finishes, offering immense versatility. It can be customized to meet specific project requirements, allowing for tailored solutions in different applications. Whether it’s choosing the right dimensions or selecting a suitable surface finish, customization options provide flexibility and ensure optimal performance.

How to Choosing a Supplier?

When choosing a supplier for aluminum diamond checker plate coil, consider factors such as experience, reputation, and the ability to meet quality standards. A supplier with a proven track record and expertise in the industry is more likely to provide high-quality products and reliable customer service. Henan Yongsheng is a manufacturer of aluminum products with 25 years of production experience, all of our products are independently produced to provide you with excellent service with fast delivery, high quality assurance, factory price and professional customer service. Nowadays, we have established long-term business relationships with customers in many countries, such as the United States, Canada, India and Southeast Asia region. We cherish the real feedback from all our customers and are committed to providing our customers with high quality, low price products and excellent service. We welcome you to visit our factory and look forward to establishing a long and good business relationship with you.

Summary

In conclusion, aluminum diamond checker plate coil is a remarkable aluminum product that offers a combination of durability, slip resistance, versatility, and aesthetic appeal. Its unique diamond checker plate pattern, coupled with the convenience of coil form, makes it a popular choice in various industries. Whether it’s for flooring, vehicle lining, decorative applications, or specialized uses, aluminum diamond checker plate coil delivers exceptional performance and reliability.