The process conditions of the chemical production process are very complex, the pressure ranges from vacuum to high pressure or even ultra-high pressure; the temperature ranges from cryogenic to high temperature; the medium is corrosive, flammable, explosive, toxic and even highly toxic. In order to ensure the safe operation of chemical equipment, the design has high requirements on the reliability of the selected chemical equipment materials. Commonly used materials for chemical equipment can be divided into two categories: metals and non-metals. Among them, metal materials are the most widely used.

There are many factors to consider when choosing materials:

① It should have sufficient strength and stiffness; good plasticity and toughness.

②Have certain corrosion resistance in the medium in which it is located.

③Good processing performance

④Extensive resources, sufficient supply, and reasonable economy.

This article will focus on explaining to you the uses of aluminum and aluminum alloys in chemical production:

What Are The Commonly Used Aluminum Alloys In The Petrochemical Industry?

The 1000, 3000, and 5000 series of aluminum alloys are the most widely utilized in equipment used in the chemical industry. Most chemical storage containers are composed of metals that are extremely resistant to corrosion. Among these alloys are the aluminum alloys 1100 and 3003. Aluminum 5052 or 6063 are ideal choices for vessels that must sustain high pressure. Alloys like 3003, 6061, 6063, and 5052 are used in some containers that are designed expressly for corrosive compounds like acetic acid, high molecular weight fatty acids, alcohols, and other substances. Ozone-containing containers need alloys like 3004, 5052, or 5454. Ammonium nitrate solution should be kept in tanks composed of alloys like 1100, 3003, 3004, 5050, 5454, 6061, and 6062.

Aluminum Sheets For Storage Tanks

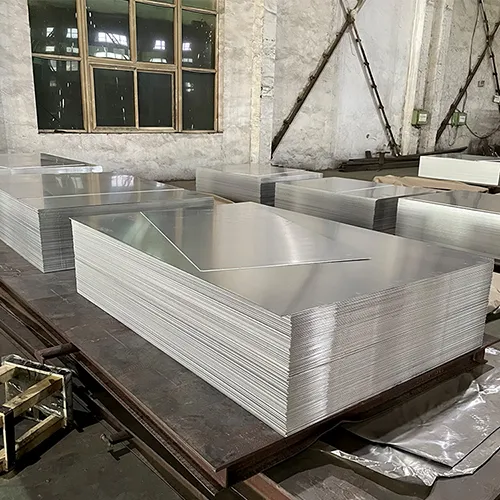

One of the most important uses of aluminum in the petrochemical industry is in storage tanks, which are generally used to store various organic liquids, non-organic liquids and vapors. Such tanks need to be made from highly corrosion-resistant alloys that can withstand the corrosive effects of many different chemicals. Aluminum alloy storage tanks mainly use 5052 H112 aluminum sheets and 5083 H111 aluminum plates, mostly medium-thick aluminum plates, which exhibit good corrosion resistance, weldability, formability, excellent processability, and are light in weight.

A complete tank truck body generally requires welding of 4-6 aluminum sheet plates. The most important tank body is made of 5083 H111 aluminum sheet. The tank lids on both sides are made of 5083-O aluminum sheets. The O-temper is softer. The can lid needs to be bent, and the partition part is also made of 5083-O. In addition, some manufacturers use 5454 H111 aluminum plates to produce tanks.

In addition, alloy 5083 aluminum sheet has high strength at low temperatures, such as LNG temperatures, and is also a high-quality material for manufacturing LNG storage tanks. It can be used to manufacture LNG storage tanks, LNG storage tank ceiling systems or brackets, etc.

Advantages Of Aluminum Tank Trucks

- Light weight: The aluminum alloy tank truck has a lighter weight than the carbon steel tank body, which can save fuel consumption and reduce costs.

- Long service life and strong corrosion resistance: Aluminum alloy is the lightest material, has stable chemical properties and is not easy to corrode. Generally, the service life of aluminum alloy tank truck bodies is about 15-20 years.

- Beautiful appearance and superior performance: Aluminum alloy has beautiful appearance and good ductility. The use of siloing technology can be compatible with the storage and transportation of a variety of materials. The adoption of a closed filling system is more than twice as efficient as traditional loading and unloading.

- High safety: The upper body of the aluminum alloy tank truck is relatively light and the center of gravity is low. Moreover, aluminum alloy is a non-flammable material and is not easy to generate sparks; it is easy to deform and can absorb the energy generated by the collision in the event of a collision, so the tank is not easy to crack.

- High recycling value: Aluminum is relatively expensive and recyclable, so when the aluminum alloy can is scrapped, its recycling price is also considerable.

Henan Yongsheng produces 5083 aluminum sheets, 5083 hot-rolled aluminum sheets, 5083 medium-thick aluminum plates, 5083 marine aluminum sheets, 5083 embossed aluminum sheets, etc. It is customized and produced on demand with complete specifications. Welcome to visit our factory.