Introduction

Embossed aluminum coil is created by using a calendering process to the surface of aluminum coils, forming many kinds of patterns. These patterns include orange peel, diamond, bean, three stars, and hemispherical designs. Aluminum embossed coil finds widespread use in packaging, construction, curtain walls, refrigeration, air conditioning, lighting, and other industries.

Specification

Alloy | Thickness | Width | Temper |

1000, 3000, 5000, 6000 Series | 0.3-3.0mm | 300mm – 1600mm | O,H12,H14,H16, H22,H24,H26,H18 |

Length | As customer’s requirement | ||

Application | Construction, Flooring, Refrigerator, kitchen cabinet, etc. | ||

Surface treatment | Embossed | ||

Patterns | Classic, 1-5 bars, Checker, Altered, Diamond, Stucco, etc. | ||

Standards | ASTM-B209, EN573-1, GB/T3880.1-2006, GB/T 24001-2016, GB/T 19001-2016 | ||

Certificate | MTC, ISO9001, SGS, ROHS, DNV, TUV, ISO14001, ABS, CCS, CE. | ||

Delivery time | Ready stock: 7-10 days, future goods: 15-30 days | ||

Loading port | Qingdao Port, Tianjin Port, Shanghai port. | ||

Payment Terms | 30% deposit by TT, 70% balance before delivery or 100% L/C at sight | ||

Price term | FOB, CIF, CFR, CNF, etc. | ||

Package | Seaworthy wooden pallet, wooden case, aluminum plate case | ||

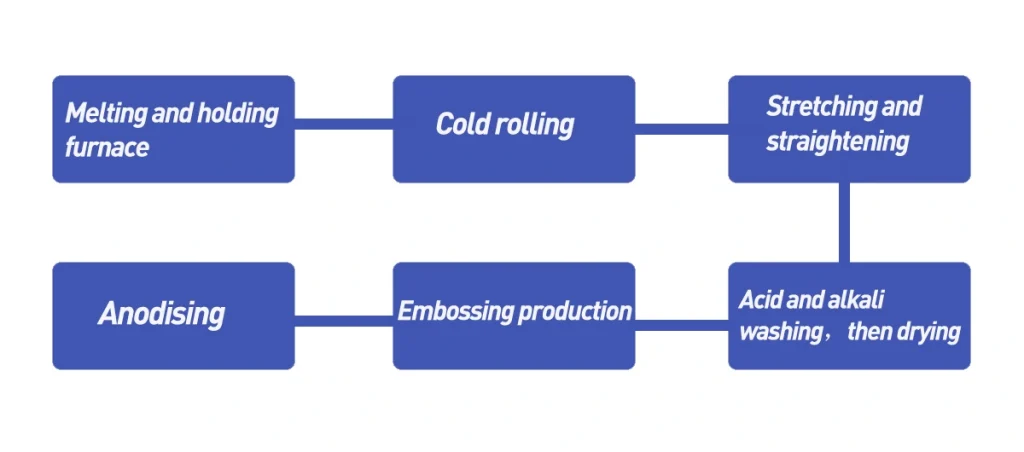

Embossed Aluminum Coil Production Process

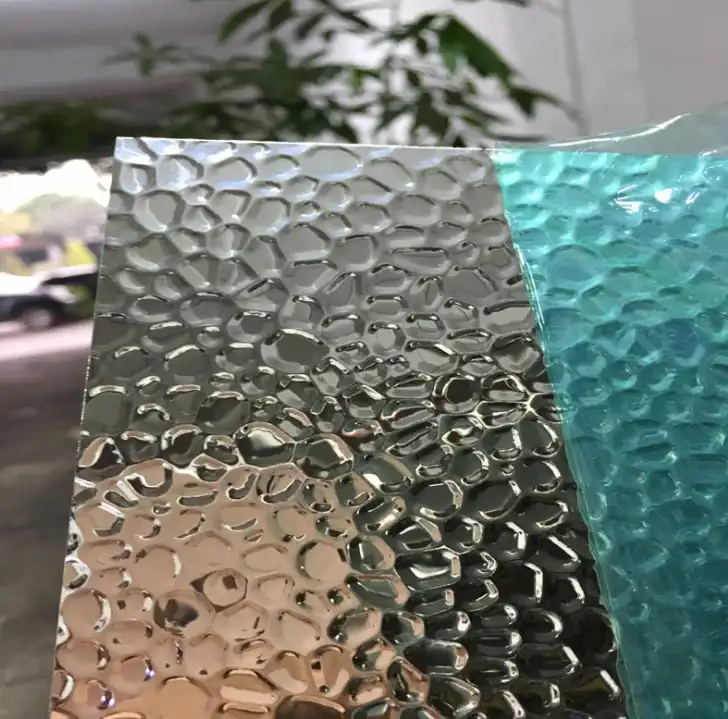

Embossed Aluminum Coil Types

Embossed Aluminum Coil Stucco Pattern

Stucco embossed aluminum coil is a textured aluminum coil with a surface finish that resembles the texture of stucco. Created through a process of rolling the aluminum coil with patterned rollers, the raised bumps or ridges on its surface enhance both its visual appearance and practical functionality. This embossed texture not only adds aesthetic appeal but also increases the durability and resistance to scratches and wear of the aluminum. It also provides improved grip and slip resistance, making it suitable for applications requiring a non-slip surface. Stucco embossed aluminum coil finds wide-ranging use in architectural and decorative applications, offering depth and dimension to surfaces such as wall cladding, ceilings, facades, and interior design elements. Its thermal and acoustic insulation properties make it ideal for construction applications, while its protective and visually appealing qualities make it popular in packaging for appliances like refrigerators and air conditioning units.

Orange Peel Aluminum Coil

The orange peel aluminum coil can be divided into two primary types: the classic orange peel pattern aluminum coil and the variant orange peel pattern aluminum coil, also known as the bug pattern. Its surface exhibits a texture that resembles the peel of an orange, which is why it is commonly referred to as the orange peel pattern aluminum roll. This type of coil finds frequent use in applications such as refrigerators, air conditioners, and packaging.

Orange peel aluminum coil is well-known for its excellent anti-rust properties. It belongs to an alloy that possesses high strength, remarkable plasticity, and corrosion resistance. Unlike alloys that can be strengthened through heat treatment, this particular alloy does not undergo further strengthening. It displays good plasticity when subjected to semi-cold work hardening. However, its plasticity decreases when hardened through cold work. Nevertheless, it maintains favorable corrosion resistance, weldability, and has limited machinability. Furthermore, it can be polished. With notable elongation and tensile strength, it meets the requirements for conventional processing techniques like pressing and stretching, while also offering high formability.

Wood Grain Aluminum Coil

Wood grain aluminum coil is a multipurpose and innovative material that combines the visual appeal of wood with the practical benefits of aluminum. The manufacturing process includes using a specialized coating to the surface of the aluminum coil, creating a realistic wood grain pattern. This coating is typically made from a combination of resins and pigments that mimic the natural color and texture variations found in many kinds of wood species.

Embossed Aluminum Coil Features

- The utilization of embossed aluminum coil contributes to environmental protection through its recyclability. Unlike other decorative materials such as glass, stone, ceramic, or aluminum plates, the aluminum coil can be completely recycled, offering a high residual value in the recycling process.

- Embossed aluminum coil provides the advantages of being lightweight, rigid, and possessing high strength. A 3.0mm thick aluminum coil weighs only 8kg per square unit while maintaining a tensile strength of 100-280N/mm2.

- The aluminum coil shows fantastic versatility in terms of its machinability, allowing for the creation of complex geometric shapes such as planes, arcs, and spheres.

- The coating on the aluminum coil is uniform and offers many kinds of colors. The implementation of advanced electrostatic spraying technology makes sure consistent adhesion between the paint and the aluminum plate, providing different color options and ample possibilities for customization.

- The embossed aluminum coil demonstrates remarkable weather resistance and corrosion resistance. By utilizing PVDF fluorocarbon paint based on KYNAR-500 and Hylurr 500, the coil can keep its integrity and appearance for up to 25 years.

- The installation and construction of aluminum embossed coil are convenient and efficient. The aluminum plates are pre-molded in the factory, eliminating the need for on-site cutting and allowing for easy fixation onto the framework.

- The embossed aluminum coil is resistant to staining, making it easy to clean and maintain. The non-adhesive fluorine coating film prevents the surface from attracting pollutants, facilitating hassle-free cleaning and preserving a pristine appearance.

Embossed Aluminum Coil Applications

- Lighting fixtures

- Solar reflective sheet

- Architectural appearance

- Indoor decoration: ceiling, wall, etc.

- Furniture, cabinets

- Elevator

- Signs, nameplates, luggage

- Automobile interior and exterior decoration

- Interior decorations: such as photo frames

- Household appliances: refrigerators, microwave ovens, audio equipment, etc.

- Aerospace and military aspects, such as China’s large aircraft manufacturing, Shenzhou spacecraft series, satellites and other aspects.

- Machine parts processing

- Mold manufacturing

- Chemical/insulation pipe wrapping

Embossed Aluminum Coil Supplier

Yongsheng Aluminum is a leading manufacturer of embossed aluminum coils, offering a range of high-quality products tailored to various industries. Our factory excels in producing coils that are widely used in refrigeration, solar heat reflectors, decorative products, lighting, and more. With a focus on excellence, we utilize top-grade materials and advanced manufacturing techniques to ensure superior product quality. Our skilled workforce and state-of-the-art machinery result in coils with enhanced thickness and strength, providing durability and optimal performance. We take pride in offering a comprehensive range of embossed finishes, allowing for customization and versatility to meet our customers’ unique needs. Additionally, our customer-centric approach prioritizes understanding and fulfilling our clients’ requirements, ensuring efficient production processes and timely delivery. We are committed to sustainability, employing recyclable materials and eco-friendly practices throughout our manufacturing process. Choose our embossed aluminum coils for reliable, environmentally conscious solutions tailored to your specific applications.