Introduction of Aluminum

Aluminum foil are made of aluminum and other metals. Aluminum is a silver-white lightweight metal commonly produced in the form of sheets, foils, powders, strips, and wires. It can form a protective oxide film in humid air to prevent corrosion.

Aluminum has a relative density of 2.70 g/cm3, a melting point of 660°C, and a boiling point of 2327°C. It has good strength and ductility. Aluminum alloys formed by adding alloying elements have better strength. The strength of superhard aluminum alloys can reach up to 600 MPa, and the tensile strength of ordinary hard aluminum alloys is generally between 200 and 450 MPa. Aluminum has good corrosion resistance and plasticity, making it suitable for various pressure processing applications. It is widely used in mechanical manufacturing

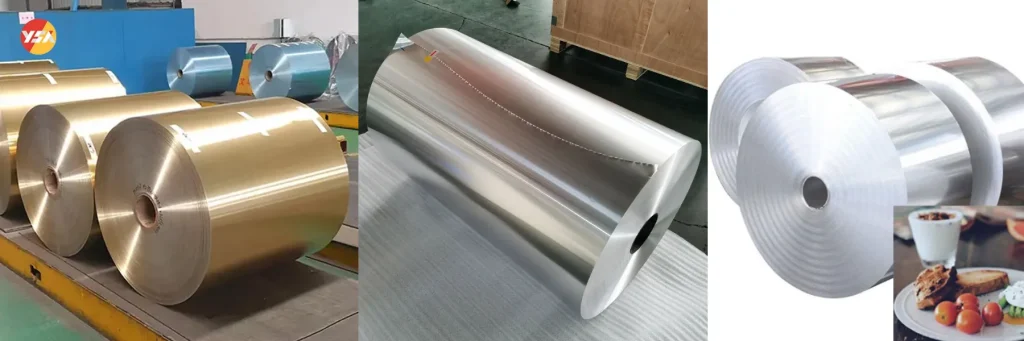

Yongsheng Aluminum Foil

- Black Aluminum Foil

- Gold Aluminum Foil

- Color Embossed Foil

- Carbon Coated Foil

- Pink Aluminum Foil

- Printed Aluminum Foil

- Red Aluminum Foil

1XXX Series: Pure aluminum foil, such as 1100 aluminum foil, has high purity and good electrical and thermal conductivity. It is widely used in electronics, food packaging, and other fields.

3XXX Series: Aluminum foil with 1.0-1.5% manganese content, such as 3003 aluminum foil, has good corrosion resistance and weldability. It is commonly used in chemical storage containers, processing equipment, and other fields.

8XXX Series: Widely used alloys, such as 8079 aluminum foil commonly used in pharmaceutical packaging, and 8011 commonly used in household foil, food containers, and aluminum foil caps.

| Series | 1000 Series | 3000 Series | 8000 Series | |

| Alloy | 1050, 1060, 1070, 1100, 1235 | 3003, 3004 | 8006, 8011, 8021, 8079 | |

| Temper | F, O, H14, H16, H18, H19, H22, H24, H26, H28, T4, T5, T6, T651, T652, T112, T351 etc. | |||

| Thickness | 0.001 mm- 0.2mm | |||

| Width | 10mm-2600mm | |||

| Length | Customization | |||

| Quality Control | Consistent thickness and width, tolerance within standards | |||

Pure Aluminum and Aluminum Alloys

Aluminum materials are divided into pure aluminum and aluminum alloys based on the presence or absence of alloying elements. Aluminum alloys are further divided into different series, such as Al-Mn alloys, Al-Cu alloys, Al-Si alloys, and Al-Mg alloys.

Pure Aluminum: Pure aluminum is classified into high-purity aluminum, industrial high-purity aluminum, and industrial pure aluminum based on its purity.

Aluminum Alloys: Aluminum alloys are obtained by adding alloying elements to pure aluminum. Depending on the added alloying elements, aluminum alloys are classified into four categories: aluminum-silicon (Al-Si) series, aluminum-copper (Al-Cu) series, aluminum-magnesium (Al-Mg) series, and aluminum-zinc (Al-Zn) series.

Heat Treatment:

Industrial pure aluminum, aluminum-manganese alloys, and aluminum-magnesium alloys can not be strengthened by heat treatment. These non-heat-treatable aluminum cannot improve its mechanical properties through heat treatment methods and can only be strengthened through cold working deformation.

However, alloys such as aluminum-copper and aluminum-magnesium-silicon can be strengthened by precipitation hardening during heat treatment. Heat-treatable and strengthenable aluminum alloys can improve their mechanical properties through heat treatment methods such as quenching and aging.

International Four-Digit Numbering System

The international Four-Digit Numbering System is recommended by the International Grade Registration Organization for Aluminum and Aluminum Alloys. For example, industrial pure aluminum includes grades such as 1070 and 1060, Al-Mn alloys include grade 3003, and Al-Mg alloys include grades 5052 and 5086.In the four-character and four-digit numbering system, the first digit represents the category of aluminum alloys.

1XXX Series: Industrial pure aluminum (aluminum content not less than 99.00%). The 1XXX series is the most commonly used series in conventional industries due to its relatively simple production process and lower price. Representative grades include 1050 and 1060.

The last two digits of the 1XXX series represent the lowest aluminum content in percentage points. For example, 1050 has an aluminum content of 99.5% and 1060 has an aluminum content of 99.6%. (The last two digits of grades in the 2XXX to 8XXX series do not have special meanings and are only used to distinguish different aluminum alloys within the same group.)

2XXX Series: Al-Cu and Al-Cu-Mn alloys. The 2XXX series aluminum alloys have higher hardness, with copper content typically around 3-5%. 2XXX series aluminum bars belong to aerospace aluminum materials and are not commonly used in conventional industries. Representative grades include 2024, 2A16, and 2A02.

3XXX Series: Al-Mn alloys. The production process of 3XXX series aluminum alloys in China is relatively advanced. The 3XXX series aluminum alloys have manganese as the main component, with a content between 1.0% and 1.5%. They are a series with good corrosion resistance. Representative grades include 3003 and 3A21.

4XXX Series: Al-Si alloys. The silicon content is usually between 4.5% and 6.0%. They have low melting points, good corrosion resistance. Representative grades include 4A01.

5XXX Series: Al-Mg Alloy (aluminum alloys with magnesium as the primary alloying element). The 5XXX series of aluminum alloys are commonly used in the aluminum sheet industry, with magnesium content ranging from 3-5%. They are characterized by low density, high tensile strength, high elongation, and good fatigue strength. However, they cannot be strengthened through heat treatment. Aluminum-magnesium alloys in the 5XXX series have a lower weight compared to other series for the same area and are widely employed in various industrial applications. Representative alloys include 5052, 5005, 5083, 5A05, etc.

6XXX Series: Al-Mg-Si Alloy (aluminum alloys with magnesium and silicon as the primary alloying elements). The 6XXX aluminum alloys primarily contain magnesium and silicon, combining the advantages of the 4XXX and 5XXX series. They exhibit good usability, easy coating, and excellent machinability. Representative alloys include 6061, which is a cold-worked aluminum forging product suitable for applications with high requirements for corrosion resistance and oxidation resistance.

7XXX Series: Al-Zn-Mg-Cu Alloy (aluminum alloys with zinc as the primary alloying element). Also belonging to the aerospace series, the 7XXX series alloys are heat-treatable and considered super-hard aluminum alloys. They offer excellent wear resistance, good weldability, but relatively poor corrosion resistance. Representative alloys include 7075.

8XXX Series: Aluminum alloys with other elements as the primary alloying element. The commonly used alloy in this series is 8011, which is mostly employed as aluminum foil. Representative alloys include 8011, 8021, 8079, etc.