Industrial aluminum foil is a type of aluminum rolled product. Aluminum foil is the aluminum product with the most processing steps, thinnest thickness, and highest difficulty. It is primarily defined by its thickness, and in the industry, aluminum products with a thickness of less than 0.2mm are generally referred to as aluminum foil. Typically, the edges are longitudinally cut and delivered in rolls. Aluminum foil is a flexible metal film that possesses advantages such as moisture resistance, airtightness, light blocking, corrosion resistance, fragrance preservation, non-toxicity, and odorlessness. Furthermore, due to its elegant silver-white luster, it is easy to process into beautiful patterns and designs of various colors.

Industrial Aluminum Foil-Battery Aluminum Foil

Battery aluminum foil is a subdivision of aluminum foil products that has experienced explosive growth in demand in the industrial sector. Although battery aluminum foil accounts for a relatively small proportion, around 3%, of the overall aluminum foil production, its production in China has seen remarkable growth. In 2021, China’s battery foil production reached 140,000 tons, doubling the production of 70,000 tons in 2020, representing a 100% year-on-year increase. This makes battery aluminum foil one of the subdivision products with rapidly growing demand in the aluminum foil industry.

Since 2022, there have been numerous investment and expansion plans in the aluminum sheet and foil sector. Due to the high demand and substantial processing fees and profits associated with battery aluminum foil, recent expansions have primarily focused on battery aluminum foil and other high-demand subdivision products such as electronic foil. These downstream industrial aluminum foils, products, including battery aluminum foil, carbon-coated aluminum foil, electronic aluminum foil, and conversion foil, are considered high-growth products. The production process for battery aluminum foil may vary, with the mainstream method being continuous casting and rolling, while some producers use hot rolling.

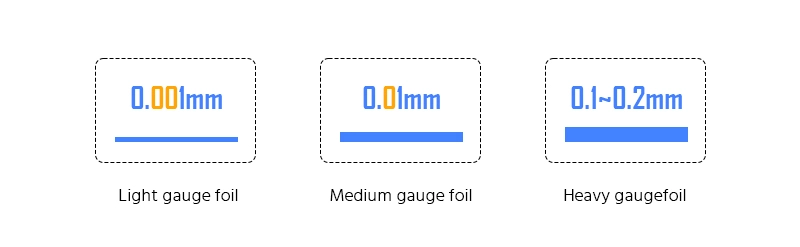

Classification by Thickness

Firstly, aluminum foil can be classified into double zero foil, single zero foil, and thick foil based on its thickness. Double zero foil refers to foil with two zeros after the decimal point when measured in millimeters (i.e., thickness < 0.01mm). Similarly, single zero foil refers to foil with one zero after the decimal point when measured in millimeters (0.01mm ≤ thickness < 0.1mm). Thick foil refers to foil with a thickness ranging from 0.1mm to 0.2mm.

Different end-use products have different thickness requirements. Generally, double zero foil is primarily used in food packaging, cigarette packaging, electronic light foils, and others. Single zero foil is used for some food packaging, pharmaceutical packaging and industrial aluminum foil like electronic circuit signal shielding, air conditioning foils, and more. Thick foil is mainly used for industrial aluminum foil like air conditioning foils, architectural decoration, and container foils.

Generally, thick foil only requires rough rolling, single zero foil needs to go through rough rolling and intermediate rolling, while double zero foil and other high-precision aluminum foils require rough rolling, intermediate rolling, and finishing rolling.

Classification by Alloy Composition

- 1xxx series – industrial pure aluminum;

- 2xxx series – aluminum-copper alloy;

- 3xxx series – aluminum-manganese alloy;

- 4xxx series – aluminum-silicon alloy;

- 5xxx series – aluminum-magnesium alloy;

- 6xxx series – aluminum-magnesium-silicon alloy;

- 7xxx series – aluminum-zinc-magnesium-copper alloy;

- 8xxx series – other alloys.

Commonly used alloy grades include 1050, 1060, 1070, 1100, 3003, 3004, 5005, 5052, 8011, and others. The most commonly used alloy for aluminum foil is the 1xxx series industrial pure aluminum, which has an aluminum content of over 99.0%. It has strong conductivity, good formability, corrosion resistance, low strength, and cannot be heat treated for strengthening. Additionally, some products use 3xxx series aluminum-manganese alloy and 8xxx series alloys.

Aluminum foil finds extensive applications in various downstream sectors, including green packaging, household, appliances, electronics and communications, transportation, printing, chemical industry, construction materials, and decoration. According to statistics from the China Nonferrous Metals Processing Industry Association, packaging and container foils account for the largest share, representing 52% of all aluminum foil usage, followed by air conditioning foils, which account for 22%.