Aluminum roofs are becoming increasingly popular among metal tile roofing, mainly because they are low cost and durable. Compared to metals such as steel, zinc, polymer, copper, etc., it is lightweight roofing, requiring less structural reinforcement when building or renovating a house with an aluminum roof, reducing installation costs. Aluminium metal itself is rust-proof and is not afraid of corrosion caused by sea spray and damage from the elements. At the same time, aluminum roofing sheet is also non-combustible, making it less likely to catch fire from wind-blown sparks or embers.

If you care about the exterior of your home, you might choose a color-coated alloy aluminum roof. A color-coated aluminum roof has a service life of more than 20 years, depending on the weather. Its life can be extended if you pay attention to care and maintenance.

Aluminum Roofing Development History:

1800 -1900: The earliest roof aluminum applications originated during the Industrial Revolution. At that time, the production process of aluminum materials was immature and expensive. Therefore, the scope of use of roof aluminum sheet was limited, mainly concentrated in some high-end buildings and special places.

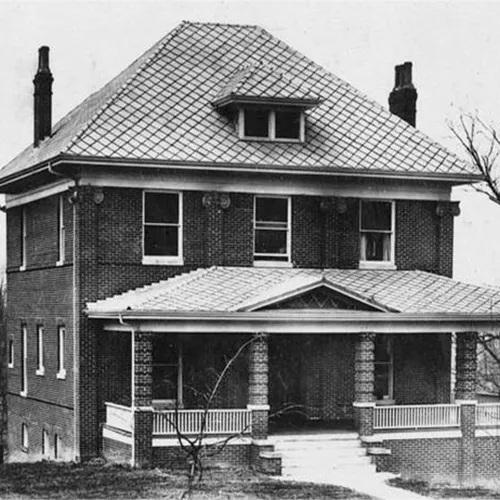

1920 – 1930: Aluminum shingles roofing grew increasingly popular in the 1920s and 1930s, and was widely used in industrial and commercial constructions. Aluminum roofing is popular due to its lightweight nature and great corrosion resistance.

1950 – 1980: The application of aluminum roofing shingles further expanded to include residential construction. As demand for public housing construction increases, aluminum roofing becomes an economically practical option. At the same time, the appearance design and color selection of aluminum roofs are gradually diversified, satisfying people’s pursuit of architectural aesthetics.

21st century: The use of new manufacturing methods and material technologies has enhanced the quality and performance of aluminum roofing sheet due to the constant growth of science and technology and the growing awareness of environmental protection. Simultaneously, the concept of sustainable development is propelling the growth of green buildings. Roof aluminum sheets, as a recyclable material, have lower energy consumption and environmental effect, meet the requirements of sustainable structures, and have gradually gained importance in the construction sector.

Aluminum Roofing Sheet:

According to the design load and usage environment of the aluminum roof, common aluminum alloy grades include 3003 aluminum, 3105 aluminum, 5052 aluminum, etc. Aluminum alloys need to have sufficient strength to withstand external loads and their own weight, as well as basic requirements such as good corrosion resistance, weldability and processability. Nowadays, customers pay more attention to the durability and aesthetics of roofs, so most people require aluminum alloy roofs to be surface treated.

What Is An Aluminum Roof System?

An aluminum roofing system is a comprehensive roof covering solution that is typically constructed from multiple components and layers designed to provide protection, insulation, drainage and decorative functions for a building. These systems are primarily made of aluminum and are popular for their lightweight, corrosion resistance and customizability. Aluminum roofing systems can be classified based on their structure and purpose. Here are some common classifications:

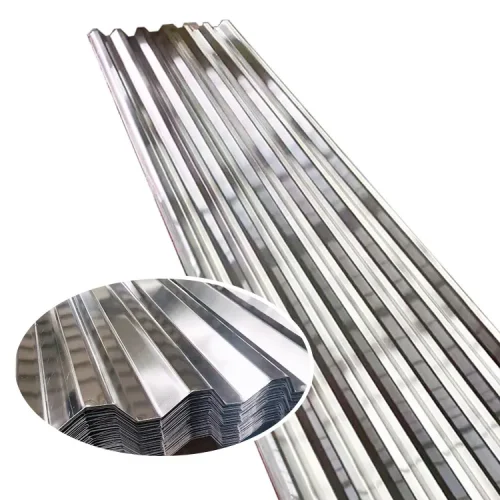

Aluminum corrugated sheet roofing system:

This is the most basic type of aluminum roofing system, usually made of sheets that have been corrugated. Bolting or overlapping are two possible ways to join corrugated plates. A wide range of industrial, agricultural, and modest residential structures can use this technology.

Aluminum sheet roofing systems:

Single or double-layered flat metal sheets make up aluminum sheet roofing systems. Various coatings and surface treatments can be applied to these sheets to meet specific performance and aesthetic requirements. Commercial and industrial structures frequently use aluminum roofing sheets.

Aluminum roof tile system:

This system mimics the look of traditional roof tiles but uses lightweight aluminum. Aluminum roof tiles can come in different shapes and colors to suit different architectural styles. They are commonly used in residential construction.

Aluminum standing seam roof system:

Aluminum standing seam roofing systems consist of long strips of aluminum sheets, often connected with standing seams, giving them a modern look. Such systems are commonly used in commercial, cultural and educational buildings, as well as luxury residences.

Solar aluminum roof system:

These systems integrate aluminium roofing with solar sheets to collect solar energy on the roof. They are an important source of renewable energy and are used in commercial and residential buildings.

Green aluminium roof system:

These systems feature vegetation cover to improve the building’s energy efficiency and environmental sustainability. They are often used in sustainable building projects and eco-friendly communities.

Roof insulation aluminum system:

These systems combine aluminum roofing and insulation to improve the thermal insulation capabilities of the building. They are frequently utilized in cold climates and in structures that demand energy conservation.

Curved aluminum roof system:

Aluminum sheets that have been twisted or curled are used in curved aluminum roofing systems to produce intricate patterns and intricate geometries. Buildings with sculpture and modern architecture frequently employ this system.

Aluminum Roofing Around The Globe:

North America:

North America is home to a wide variety of architectural designs, such as industrial-style structures, modernist structures, and traditional American residences. Residential, commercial, and industrial structures frequently use aluminum roofing sheets. Anodes such as 6061 and 3003 aluminum sheets are common materials for aluminum roof sheets.

European region:

Europe’s architectural styles are diverse and diverse, including classicism, Gothic, modernism, and postmodernism. Aluminum roof sheets are commonly made from aluminum alloys such as aluminum 6063 and aluminum 5052. These materials are processable and corrosion resistant, and they are adaptable to Europe’s changing environment.

Asia region:

Eastern traditional architecture, modern Asian style, and high-tech architecture are all found in the Asian region. Aluminum alloys such as 6063 and 3003 aluminum are common materials for aluminum roof sheets.

Australia and New Zealand:

Australia and New Zealand are known for their distinctive architectural designs, which include modernism, coastal-style architecture, and traditional Victorian architecture. Aluminum alloys like 5052 and 3003 are frequently utilized as materials for aluminum roof sheets.

Aluminum Alloy Roof Success Stories:

Sydney Opera House

Scandinavian Homes

Tips For Maintaining Your Aluminium Roof:

- Clean regularly.

- Check for leaks and seals.

- Check fasteners regularly.

- Protects against scratches and breakage.

- Check attachments and drainage systems.

- Check coatings and paints regularly.