Pharmaceutical aluminum foil is widely used internationally as a packaging material for pharmaceutical products such as capsules and tablets.

Due to its direct contact with edible drugs, there are strict requirements for pharmaceutical aluminum foil according to Chinese national standards.

Yongsheng Aluminum has mature processing technology in 8011, 8021 aluminum foil, and 8079 aluminum foil, which are primarily used for blister packaging of pharmaceutical capsules and tablets, as well as bag packaging for powder granules and liquid formulations.

- Blister Foil

- PTP Pharmaceutical Aluminum Foil

- Cold Stamped Medicine Foil

- 8011-H18 Aluminum Foil for Medical Packaging

- Capsule Aluminum Foil Board

The commonly used pharmaceutical aluminum foils in the market are 8011 aluminum foil and 8021 aluminum foil. 8011 aluminum foil is usually below 0.05mm in thickness, while 8021 aluminum foil is typically above 0.05mm in thickness.

Aluminum Foil Manufacturing Process

Aluminum foil production process includes:

Billet inspection-Open billet rolling-Open middle split rolling-Combined roll rolling-Roll finished product-Slitting-Furnace annealing-Finished product packaging.

In the production process, for the pharmaceutical aluminum foil surface and performance control, the main attention to the following points:

- Quality control from the source, strict inspection of blanks;

- In the rolling process, control the surface quality by cleaning the rolls, controlling the roughness, selecting suitable rolling oil, reducing the viscosity of the oil and controlling the running speed of the machine;

- In the slitting process, ensure that the edge portion of the aluminum coil is neat to avoid quality problems such as ruffled edges;

- In the annealing process, control the annealing time and temperature according to the performance requirements of pharmaceutical aluminum foil to ensure clean oil removal.

Through the above control measures, the appearance and performance of pharmaceutical aluminum foil can be effectively guaranteed to meet the strict requirements for pharmaceutical packaging.

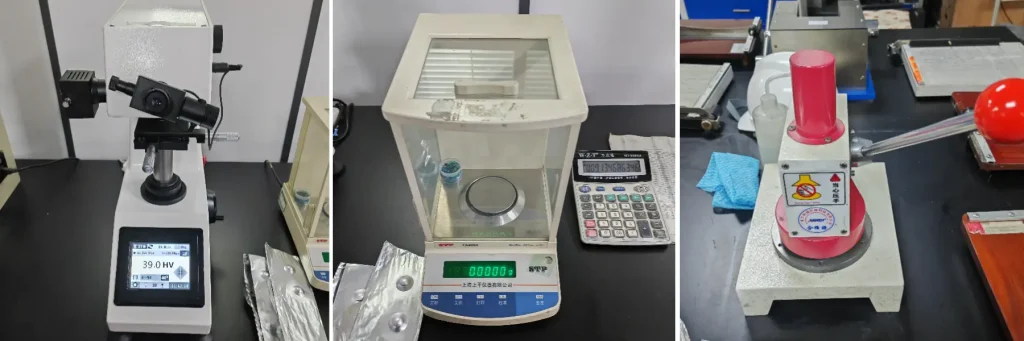

Laboratory Test

The requirements for pinholes: Pinholes in aluminum foil can affect its barrier properties, especially in pharmaceutical packaging, as they can easily allow oxygen, water vapor, and light to penetrate, leading to a decrease in the efficacy of the drugs.

Therefore, for pharmaceutical aluminum foil, the national standard requires that there should be no pinholes with a diameter greater than 0.3 millimeters, and the number of pinholes with a diameter between 0.1 to 0.3 millimeters should not exceed 1 per square meter. Yongsheng Aluminum Industry has dedicated 25 years of research to aluminum foil, with complete testing certificates, ensuring that their products meet the national standard requirements.

Uniformity of thickness and tensile strength: Non-uniform thickness of aluminum foil can result in difficulties in achieving the standard coating amount of adhesive during the coating process, thereby affecting the heat sealing strength of the aluminum foil.

Low tensile strength can lead to foil breakage during actual processing due to tension issues, which is not conducive to normal production. Yongsheng conducts a series of laboratory tests on pharmaceutical aluminum foil raw materials to ensure that their aluminum foil is suitable for production, meets the standards, and achieves top-quality in the industry.

Yongsheng food-grade pharmaceutical aluminum foil undergoes rigorous pinhole detection, oil removal processes, and plate shape control. The products meet the requirements of food-grade safety and hygiene, and they also have advantages such as high elongation.

Yongsheng is a supplier of aluminum foil raw materials for various pharmaceutical production enterprises both domestically and internationally.

Why is Aluminum Foil Used in Pharmaceutical Packaging?

As a non-permeable, light-blocking material, aluminum foil possesses excellent barrier properties, making it effective in preventing moisture and humidity. Some medications can deteriorate when exposed to oxygen, so aluminum foil helps protect their quality, maintain the dryness and stability of medications.

Furthermore, aluminum foil can be sealed using heat sealing or cold sealing, ensuring the integrity of pharmaceutical packaging and preventing contamination and oxidation. Additionally, aluminum foil can be combined with other materials to form multi-layered composite materials, further enhancing the performance and functionality of pharmaceutical packaging.

Aluminum foil serves as an excellent packaging material, safeguarding the quality and safety of pharmaceuticals by reducing their exposure to the external environment and contamination, thereby extending their shelf life.