Introduction

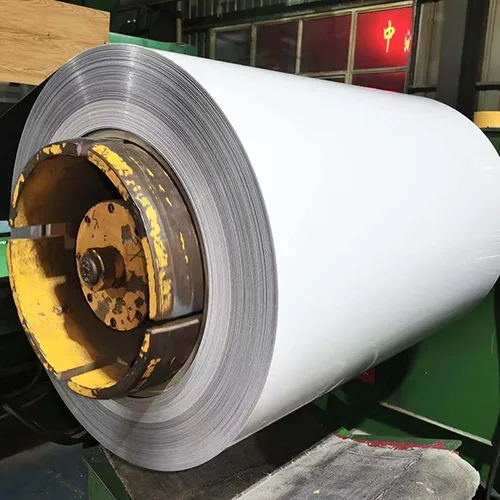

Colored aluminum sheet metal is a product after deep processing of the surface of aluminum sheet and coil, can greatly improve the weather resistance and corrosion resistance of aluminum coil sheet, and can be painted in a variety of colors, increasing the decorative properties of aluminum. It is a metal material commonly used in modern construction, furniture, decoration and other fields, color painting not only plays a decorative beautification effect, but also makes the aluminum plate become more anti-slip and wear-resistant.

Types of Color Aluminum Sheet

According to different evaluation and classification standards, colored aluminum sheets can be divided into many different types:

- Based on the base material material, it can be divided into: 1060 color aluminum sheet, 1100 color aluminum sheet, 3003 color aluminum sheet, 3004 color aluminum sheetand other categories. The hardness and strength of different aluminum alloys are not the same.

- Based on the paint thickness, it can be divided into: single-coated colored aluminum sheetand double-coated colored aluminum sheet.

- Based on the paint material, it can be divided into three types: polyester paint colored aluminum plate, fluorocarbon paint colored aluminum plate, and epoxy paint colored aluminum plate. Yongsheng can produce PE colored aluminum sheets and PVDF colored aluminum sheets. Its main characteristics are as follows:

| Properties | PE | PVDF |

| Corrosion Resistance | 2-10 years | 20-30 years |

| Weather Resistance (Mainly UV Rays) | Obvious color difference appears on the sunny side in 2-5 years | No color difference in 10-20 years |

| Brightness | Well | Ordinary |

| Price Comparison | There is a huge difference, usually PE is $450 cheaper than PVDF. | |

Color Coated Aluminum Sheet Advantages

Because the surface is coated with fluorocarbon polymer resin, color aluminum coil has strong corrosion resistance, anti-ultraviolet erosion performance, long-term usage of the color does not fade, better heat storage to achieve thermal insulation effect, and so on, as follows:

- Color coated aluminum coil sheet has a low light absorption rate, is non-reflective, has high heat insulation, and emits no light pollution.

- Sound insulation, fire protection, and corrosion resistance;

- Simple structure and light weight;

- Simple transportation and installation;

- Anti-aging, good resistance, long service life;

- Not easily peeling and delaminating; good paint adhesion.

Color Aluminum Sheet Alloy Series

The main materials of color coated aluminum sheet are 1xxx series, 3xxx series and 5xxx series. The characteristics and differences of each series of aluminum plate are as follows:

1000 series is pure aluminum, and because it does not contain any other alloying elements, the manufacturing process is simpler, and the price is also lower. It is one of the most often used materials in color coated aluminum sheet. The material is soft and the strength of 1xxx series aluminum sheet is low. The most frequent material is 1060 aluminum plate.

3000 aluminum manganese anti-rust alloy series, with a manganese content of 1.0-1.5, has good corrosion resistance, higher hardness than the 1000 series, and better tensile performance than the 1xxx series, and is one of the most commonly used aluminum alloy metal materials in the color-coated aluminum coil plate. Aluminum alloy commonly used for 3003 and 3004 aluminum sheet, although more expensive than 1060. Because 3004 aluminum alloy contains manganese and magnesium, it has a stronger strength than 3003 aluminum sheet.

5000 series is aluminum-magnesium alloy, magnesium content between 3.0-5.0, the main characteristics of low density, high tensile strength, high elongation aluminum. From the mechanical properties, 5 series aluminum alloy than 3 series aluminum tensile strength is higher, the performance is also better than 3xxx series aluminum sheet, the price will be higher, commonly used materials for 5052 aluminum alloy.

Common Uses of Color Coated Aluminum Sheet

Color coated aluminum sheet is mainly used in building decoration materials, appliance panels, food packaging, transportation and other fields.

- Building decoration materials: aluminum roofing sheet, ceiling panels, aluminum honeycomb panels, insulation panels, aluminum rolled even doors, aluminum shutters, aluminum curtain wall sheet.

- Home appliance materials: range hoods, refrigerators, air conditioners, refrigerator freezer compartment panels, etc.

- Food packaging materials: can tops, can rings, aerosol spray caps.

- Transportation: van shells, van interiors, vehicle interiors.

Factors of Purchasing Color-coated Aluminum Sheets:

- Application scenarios: The requirements for the size and type of wear kinetic energy in real environments are closely related to the wear-resistant coating materials. If you are using color-coated aluminum strips for exterior construction, choose a coating material that is economical and resistant to UV rays, humidity and temperature changes.

- Coating material: The harder the wear-resistant coating of color-coated aluminum coils, the better the wear resistance. The less likely it is to have defects such as scratches and peeling paint.

- Service life: The wear-resistant coating needs to be used for a long time in different environments and resist corrosion. You need to choose better corrosion-resistant plates and paints. Under normal circumstances, the service life of PE color coated aluminum sheets can reach 15 years, and the service life of PVDF color coated aluminum sheets can reach about 25 years.

- Cost: On the premise of meeting your application needs, you should choose a coating material with affordable price and stable performance.

YSA Factory

Yongsheng Aluminum produces and sells 5 specifications of aluminum alloys such as 1000, 3000, 5000, 6000, 8000 series, etc. The main products are CTP/PS plate substrate, aluminum foil for capacitors, single-zero foil, double-zero foil, electronic foil, alloy material, deep-drawn material, brazing plate, medium-thickness plate, pure aluminum sheet, honeycomb aluminum sheet, alloy aluminum plate, special gauge aluminum sheet, deep-drawn aluminum sheet, coated aluminum sheet, anti-rust aluminum sheet, anti-skid aluminum sheet, aluminum sheet for automobile fuel tanks, aluminum sheet for cables, marine aluminum sheet, orange peel embossed aluminum sheet, aluminum circles, corrugated aluminum roofing sheet, aluminum sheet for radiator fins, aluminum sheet for molds, color coated aluminum sheet, hot rolled medium-thickness aluminum sheet; specifications and dimensions of performance can be tailor-made to meet the actual needs of users. If you have demand, please contact us immediately.