3003 Aluminum Sheet for Battery Shell

3003 aluminum sheet for battery shell has the characteristics of corrosion resistance, impact resistance, good stamping and tensile properties, and is not easy to break or leak. The power battery casing made of 3003-h14 aluminum plate can reduce the weight of the battery, increase the battery capacity density, make the battery work stably, indirectly reduce the weight of the vehicle, and increase the vehicle’s endurance.Yongsheng Aluminum strictly controls the production process and provides standardized products with low lug rate, excellent performance, and can be shipped and exported globally.

Product Introduction

3003 aluminum sheet for battery shell has low density and soft material. It has the advantages of easy stretching and molding of power battery shells. It has been used by many companies for battery packaging. Especially the lithium battery combination module of new energy vehicles. The lithium battery combination is composed of several battery boxes.

3003 H14 aluminum sheet is easy to process and form, and has high temperature corrosion resistance, good heat transfer and electrical conductivity. The aluminum alloy power battery shell (except the shell cover) can be stretched and formed at one time. Compared with the stainless steel shell, the box can be omitted. The bottom welding process is the best choice for manufacturing power battery cases.

Product Specifications

| Name | 3003 Aluminum Sheet for Battery Shell |

| Alloy Grade | 3003 |

| Temper | O, H14 |

| Thickness | 0.8-3.0mm |

| Width | 100-2650mm |

| Length | Any |

| MOQ | 1 Ton |

| Sample | Free |

| Delivery Time | 7-25 days after order confirmation |

| Standards | GB/T 33227-2016、JIS H4000、ASTM B209、EN 485 |

| Price Terms | FOB, CIF, CFR, CNF, etc. |

Product Properties

3003 h14 aluminum composition

| Elements | Value (%) |

| Si | 0.6 |

| Fe | 0.7 |

| Cu | 0.1 |

| Mn | 1.13 |

| Mg | – |

| Cr | – |

| Zn | 0.1 |

| Ti | – |

| Al | Remain |

| Tensile strength (MPa) | 150 |

| Yield strength (MPa) | 145 |

| Hardness (HB) | 40 |

3003 h14 Aluminum vs 6061

3003 H14 aluminum is a soft alloy with relatively low strength. 6061 is a heat-treatable alloy with higher strength. In the T6 state, its tensile strength is approximately 290 MPa. 3003 H14 is commonly used in applications requiring deep drawing, spinning or forming.

Aluminum 6061 is often used in machining, welding and manufacturing applications and is widely used in structural parts such as aircraft parts, ship accessories, bicycle frames, auto parts, sports equipment, etc.

Product Applications

Product Advantages

The power battery casing is generally made of one-piece stretch molding with uniform wall thickness and no cracks. It is waterproof, moisture-proof, and violent-resistant. It requires excellent raw material performance and good processability. The 3003 deep-drawn aluminum plate produced by yongsheng Aluminum has good formability and is mainly used as deep-drawing materials. The 3003 aluminum alloy plate is used as stamping parts and shows good forming processing characteristics, high corrosion resistance, good weldability and electrical conductivity.

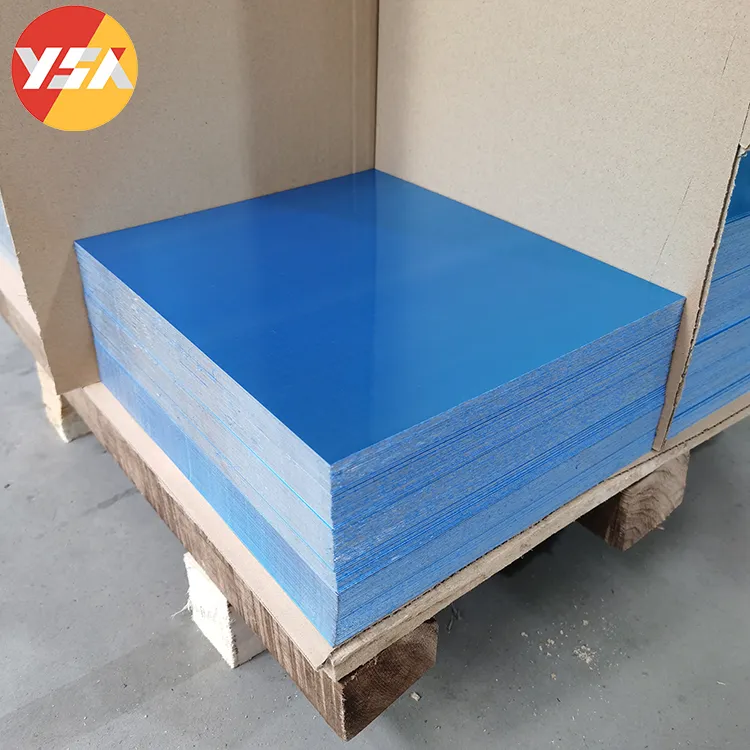

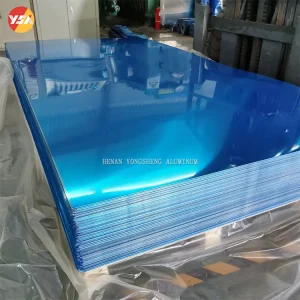

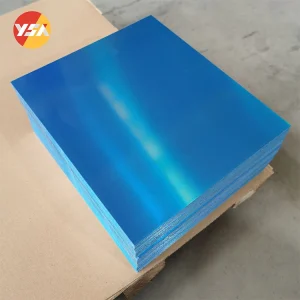

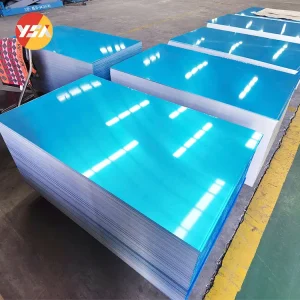

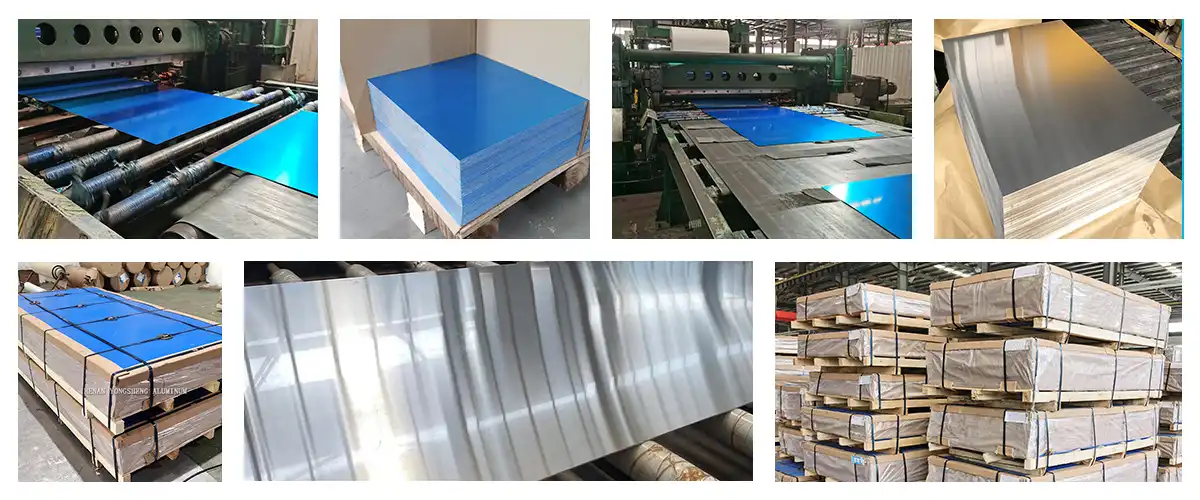

Product & Packaging Photos

Why Choose Us

Yongsheng Aluminum is a leading aluminum products manufacturer&supplier in China with 25 years of export experience. Our outstanding product quality, price, and always on-time delivery has won us many long term partners and gained a great reputation worldwide. We provide one-stop product solution for both CC&DC aluminum products.

Contact us to get your quotation.

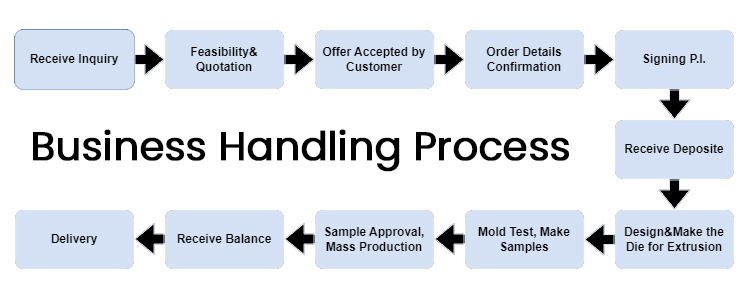

Business Handling Processes