The standard thickness of aluminum foil is essential for maintaining quality, meeting customer requirements, and optimizing production processes. Ensuring consistent and reliable production has great impact on manufacturing.

Yongsheng Aluminum Foil Specifications

| Alloy | 1xxx Series: 1050, 1060, 1070, 1100, 1235 |

| 3xxx Series: 3003, 3004 | |

| 5xxx Series: 5052 | |

| 8xxx Series: 8011, 8021, 8079. | |

| Temper | F, O, H14, H16, H18, H19, H22, H24, H26, H28, T etc. |

| Thickness | 0.006-0.2mm. |

| Width | 20mm-1600mm (1.6m). |

| Dia | Inner: 76\152mm; Outer: Support Customization. |

| Delivery Time | Ready stock 7-10 days, on time delivery |

| Loading Port | Qingdao Port, Tianjin Port, Shanghai port. |

| Price Terms | FOB, CIF, CFR, CNF, etc. |

| Quality Control | Mill Test Certification is supplied with shipment, Third Party Inspection is acceptable. |

Consistency and Standard Thickness of Aluminum Foil

The specified thickness directly impacts the performance of the foil in various applications. For example, in the packaging industry, a consistent thickness ensures reliable sealing and barrier properties, preventing moisture, light, and oxygen from affecting the contents of packaged products. Deviations in thickness can compromise the foil’s ability to provide an effective barrier, leading to decreased product integrity and potential spoilage.

Maintaining a standard thickness is crucial for meeting customer expectations. Customers rely on aluminum foil products with consistent thickness for their specific needs, such as cooking, baking, or packaging. Variations in thickness can result in inconsistencies in cooking times, heat distribution, and overall product performance, leading to customer dissatisfaction.

Additionally, adherence to industry standards and regulations is imperative for manufacturers. Standardized thickness requirements are often specified to ensure product quality, safety, and compatibility across different industries. Non-compliance with these standards can lead to rejected products, loss of customers, and potential legal issues.

Ensuring Consistency and Quality

Yongsheng Factory takes pride in producing high-quality aluminum foil products. In our commitment to excellence, we recognize the significance of maintaining a consistent standard aluminum foil thickness.

1. Manufacturing Techniques for standard thickness of aluminum foil

Standard thickness of aluminum foil is typically produced through a continuous rolling process. The manufacturing techniques involve feeding aluminum coils through rolling mills with precise gap adjustments. The rolling process determines the foil’s thickness, with tight control over the reduction ratio and tension to achieve the desired specifications. Advanced monitoring and automation systems can help maintain accuracy and consistency throughout the production line.

2. Quality Control Measures

To uphold our commitment to quality, Yongsheng Factory implements rigorous quality control measures throughout the production process. These measures include:

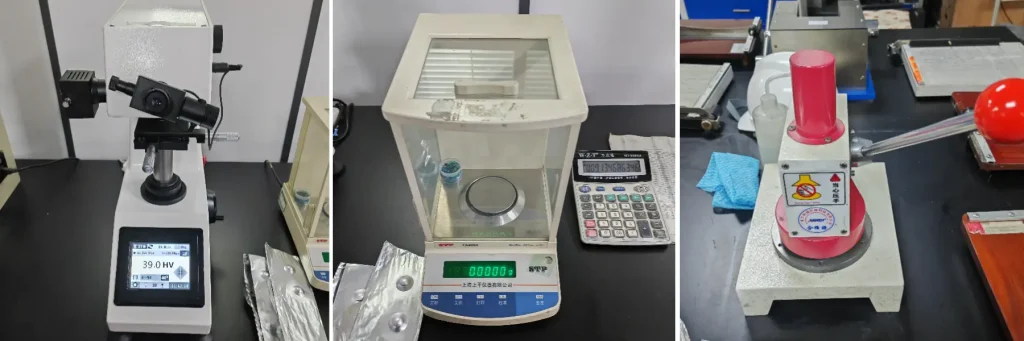

Advanced Manufacturing Techniques: We utilize state-of-the-art rolling mills and precision equipment to manufacture aluminum foil with precise thickness control. Our experienced technicians and operators are trained to operate and maintain these machines to ensure accurate and consistent results.

Regular Calibration and Maintenance: We conduct regular calibration and maintenance checks on our equipment to maintain accuracy. This includes calibrating micrometers and other measurement tools used to verify the thickness of the aluminum foil.

Statistical Process Control (SPC): We implement SPC techniques to monitor the foil thickness during production. Control charts and statistical analysis allow us to identify any process variations promptly, enabling corrective actions to maintain consistent thickness.

In-line Inspection Systems: Yongsheng Factory has invested in advanced in-line inspection systems that provide real-time measurement and feedback. These systems ensure accurate and reliable standard thickness of aluminum foil measurements during production.

Sampling and Testing: Periodic sampling and testing of standard thickness of aluminum foil using micrometers or non-destructive testing methods can provide valuable data for quality assurance.

3. Customer Satisfaction and Compliance

Yongsheng Factory recognizes that customer satisfaction and compliance with industry standards are paramount. By maintaining a consistent standard aluminum foil thickness, we meet customer expectations and ensure compatibility with various applications.

Furthermore, compliance with industry standards and regulations is of utmost importance. Our commitment to consistent thickness aligns with these standards, ensuring that our aluminum foil products meet the necessary requirements for quality, safety, and performance. We continuously monitor changes in standards and update our manufacturing processes accordingly to stay ahead of evolving industry expectations.

Yongsheng Factory recognizes the importance of standard thickness of aluminum foil in delivering high-quality products. Through advanced manufacturing techniques, robust quality control measures, and a commitment to customer satisfaction and compliance, we ensure the consistency and reliability of our aluminum foil products. By maintaining precise thickness control, we enable our customers to achieve optimal performance in their applications. Trust Yongsheng Factory for your aluminum foil needs, and experience the quality and consistency we bring to every product we manufacture.

4. Continuous Improvement and Process Optimization

To enhance manufacturing efficiency and maintain consistent thickness, factories should focus on continuous improvement initiatives. This includes:

Process Optimization: Analyzing the manufacturing process to identify bottlenecks, optimize rolling parameters, and reduce variability can lead to improved thickness control.

Training and Skill Development: Providing comprehensive training programs to operators and technicians on proper measurement techniques, equipment handling, and quality control procedures can enhance overall process control and reduce errors.

In the manufacturing industry, maintaining a standard thickness for aluminum foil is vital to ensure product quality, meet customer expectations, and optimize production efficiency. Implementing stringent quality control measures, utilizing advanced inspection systems, and continuously improving processes are key strategies for achieving consistent thickness. By prioritizing quality and process optimization, factories can enhance their competitiveness, deliver reliable products, and build strong relationships with customers in various sectors that rely on aluminum foil.