The thickness of aluminum foil is usually measured in microns or millimeters, and the commonly used thickness range is 10-200 microns (0.01-0.2mm). If you need aluminum foil with a thickness below 10 microns or above 200 microns, you can contact the factory for special customization.

We know that aluminum foil can be divided into thick foil, single zero foil and double zero foil according to thickness difference.

①Thick foil: foil with a thickness of 0.1-0.2mm

②Single zero foil: foil with a thickness of 0.01mm and less than 0.1mm.

③Double zero foil: usually aluminum foil with a thickness less than 0.01mm, that is, 0.005-0.009mm. So, for aluminum foil with smaller thickness, how should we know the thickness of aluminum foil?

How to Find the Thickness of Aluminum Foil?

A stack of 1,000 sheets of aluminum foil would be about 16 millimeters (0.63 inches) thick. However, the aluminum foil thickness ranges from ultra-thin foil used for delicate applications to thicker foil used for heavy-duty purposes.

To Find the Thickness of Aluminum Foil, we can use both direct methods and indirect mathematical calculations.

Direct Measurement - Tools

To measure the precise thickness of aluminum foil directly, you can use the tools you have available.

1. Calipers

If you have a set of calipers, you can use them to measure the thickness of the foil. Calipers are precision measuring tools. Simply open the calipers and place the foil between the jaws. Gently close the jaws until they make contact with the foil, and then read the measurement on the caliper display. This will give you the thickness of the aluminum foil in the units of measurement displayed on the caliper (e.g., millimeters or inches).

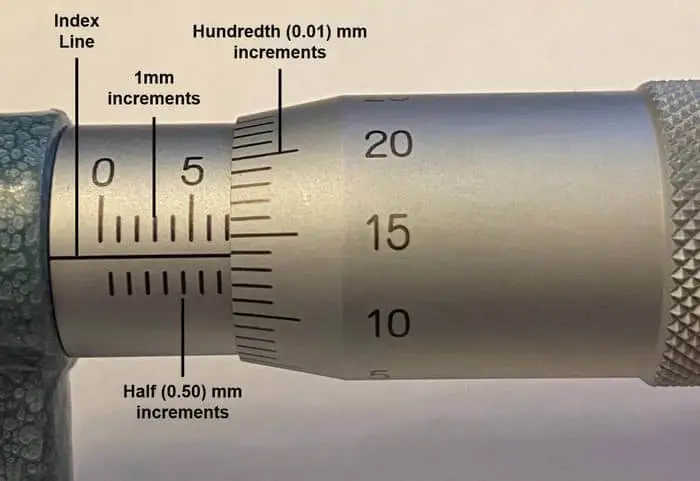

2. Micrometer(Screw gauge)

A micrometer is another precise tool that can be used to measure the thickness of aluminum foil. Similar to calipers, a micrometer also has jaws that can be adjusted to grip the foil. Place the foil between the jaws and tighten them gently until they touch the foil, and then read the measurement displayed on the micrometer.

See how to read micrometers at the end of the article.

3.Digital devices

Digital devices, like digital thickness gauges and optical Interferometry. They’re advanced versions of traditional mechanical micrometers that provides a digital readout of the measurement offers a easier reading of measurements and the ability to switch between different units of measurement with the press of a button. But these digital devices are much more expensive than the two types of machinery previously mentioned, commonly seen in laboratories and high end industrial manufacturing places.

Micrometers vs Calipers

Micrometers and calipers are both commonly used precision measuring tools in industries such as manufacturing, engineering, and construction. They are capable of measuring various dimensions such as thickness, diameter, length, and width.

1.The main differences between micrometers and calipers lie in their accuracy and the types of measurements they can perform. Micrometers are known for their high accuracy, typically measuring up to 0.001mm (one-thousandth of a millimeter) or 0.0001 inches (or ten-thousandth of an inch) while calipers can only measuring up to one-thousandth of an inch (0.001″) or a hundredth of a millimeter (0.01mm) if it uses a metric scale.

2. Another difference is the measurement range. Calipers generally have a wider measurement range, typically from 0-6 inches, allowing them to measure larger objects. On the other hand, micrometers have smaller measurement ranges, typically 0-1 inch or 1-2 inches, but offer higher precision within that range.

3.In terms of design, calipers are generally considered simpler and more user-friendly. They often have a sliding jaw mechanism that can be easily adjusted for different measurements. Micrometers, on the other hand, have a screw mechanism that requires more precise handling.

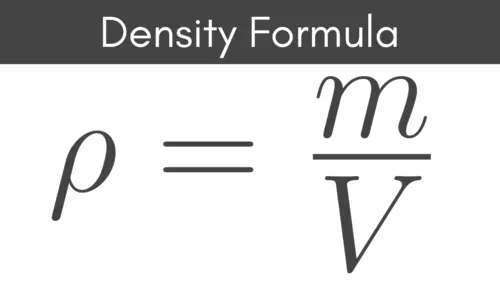

Formula Measurement - Density

How to determine the thickness of aluminum foil using physical formula?

Determining the thickness of aluminum foil involves using the weight of a known area of the foil and its density to calculate the thickness. Assuming the aluminum foil is uniform. Having the weight, area and density, then you can calculate the thickness.

Thickness (cm) = Weight (grams) / (Area (cm2) x Density (grams/cm3))

By dividing the weight in grams by the product of the area in square centimeters and the density in grams per cubic centimeter, you can determine the thickness of the object in centimeters.

Weight: The weight of the object is typically measured in grams or another unit of mass. It represents the total mass of the object.

Area: The area refers to the surface area of the object that you are considering. It is usually measured in square centimeters (cm2). The area can be calculated by multiplying the length and width of the object if it has a regular shape or by other appropriate methods for irregular shapes.

Density: Density is the mass per unit volume of a substance and is typically expressed in grams per cubic centimeter (grams/cm3). It represents how much mass is contained within a given volume. The density of a material can often be found in reference tables or measured experimentally.

Thickness: The thickness of the object is what you are trying to determine using the given weight, area, and density. The thickness of aluminum foil is typically measured in Microns (µm).

Use Micrometer to Measure Alufoil Thickness

1. Read the whole number measurement on the fixed scale of the micrometer.

2. Check if the half-scale line is exposed. If it is exposed, record it as 0.5mm; if not, record it as 0.0mm.

3. Read the movable scale and estimate the measurement. Each increment on the movable scale represents a fraction of a unit (e.g., 0.01mm).

4. Add the readings from the fixed scale, half-scale, movable scale, and estimated reading to obtain the final measurement of the aluminum foil thickness.

Thickest Aluminum Foil

Heavy-duty aluminum foil: Beyond 0.2mm, extra thick aluminum foil is available for specific applications that require increased durability and strength. Common thicknesses for extra thick foil include 0.250mm, 0.300mm, 0.350mm, and so on. These foils are commonly used in heavy-duty industrial applications, such as insulation for high-temperature environments, structural components, and specialized packaging.

The thickness of aluminum foil can vary depending on the specific product and its intended use. Typically, household aluminum foil, often referred to as “standard” or “regular” aluminum foil, has a thickness of around 0.016 millimeters (0.00063 inches). However, aluminum foil is manufactured in various thicknesses to meet different needs. Thicker aluminum foil, known as heavy-duty aluminum foil, is also available. Heavy-duty aluminum foil is generally thicker and more durable than standard aluminum foil, making it suitable for applications that require extra strength and resistance to tearing or puncturing.

Common alfoil Thickness

Aluminum foil sheets are available in various types, including standard duty, extra heavy duty, and heavy duty foils. These foils differ in their thickness and strength, offering different levels of tear resistance.

1. Ultra-thin foil: Below 0.006mm, common thicknesses for ultra-thin foil include 0.003mm and 0.005mm. These foils are typically used for specialized applications such as electronic devices and tobacco packaging.

2. Thin foil: Within the range of 0.01mm to 0.04mm, common thicknesses for thin foil include 0.010mm, 0.015mm, 0.020mm, 0.025mm, 0.030mm, and 0.035mm. These thin foils find wide application in areas such as food packaging, medical supplies, and household items.

3. Medium thickness foil: Within the range of 0.05mm to 0.1mm, common thicknesses for medium thickness foil include 0.050mm, 0.060mm, 0.070mm, 0.080mm, 0.090mm, and 0.100mm. These foils are commonly used in cooking, baking, industrial packaging, and more.

4. Thick foil: Above 0.1mm, common thicknesses for thick foil include 0.150mm, 0.200mm, and thicker specifications. These thick foils are typically used in industrial applications such as insulation materials, construction materials, aerospace, and more.