New technology advances the HVAC industry and these changes improve indoor comfort. One of these improvements includes upgrading the evaporator coil material from copper to aluminum. Evaporator coils are very important to the proper operations of the cooling cycle. They loop the refrigerant through the system and dispel hot air to the outside.

Air Conditioner History

In the past, copper was the most popular material choice for manufacturing coils. For a long time, copper was exclusively used in HVAC systems due to its numerous advantages. However, this made air conditioners expensive, making them unaffordable for many people. Around 1970, General Electronics revolutionized the air conditioning industry by introducing aluminum as an alternative material for coils. The aluminum coils in an air conditioner significantly reduced the manufacturing cost compared to copper, resulting in lower prices for air conditioners. This made air conditioning more accessible, turning it into a luxury that most people could afford. Since then, there has been an ongoing debate regarding the superior material for coil production.

Importance of Coils in Air Conditioners

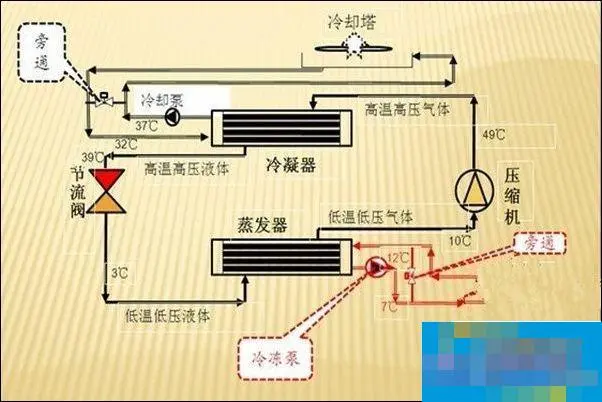

Coils in air conditioning systems play an ultimate role as they are central to the refrigeration process. This process includes the conversion of a refrigerant gas from a gaseous state to a liquid state through compression, and then back to a gas state by absorbing heat from the surroundings. The refrigeration process can be divided into four main stages, each serving a specific purpose.

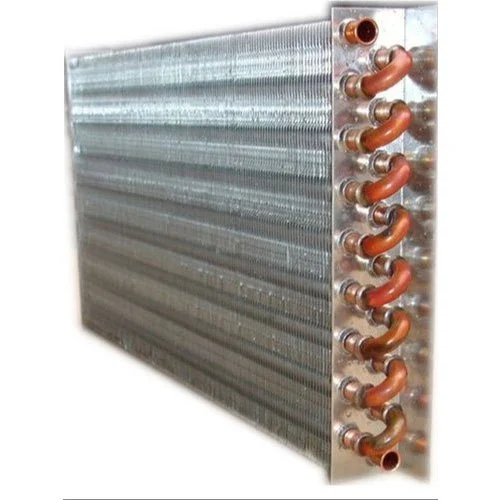

During the compression stage, the gas is pressurized and transformed into a high-pressure, hot liquid. Subsequently, in the condensation stage, the high-pressure, hot liquid refrigerant passes through a coil. In this coil, heat is released into the outside air, causing the refrigerant to cool down and convert into a liquid. This is the precise stage where coils are used.

Following condensation, the refrigerant experiences a transition in the expansion valve, which converts the high-pressure liquid into a low-pressure liquid. The final stage, evaporation, takes place in an evaporation coil, where the low-pressure liquid absorbs heat from the room and changes from a liquid to a gas state. It is important to note that the evaporation process occurs within the indoor unit, while the other stages take place in the outdoor unit, particularly in the case of split air conditioners.

To summarize, coils in air conditioners play a critical role in the refrigeration process. During the condensation stage, the coils aid in the dissipation of heat from the high-pressure, hot liquid refrigerant, resulting in its cooling and transformation into a liquid form. This process is essential for the overall functionality of air conditioning systems as it facilitates the absorption and removal of heat from the room, thereby providing a cooling effect.

Aluminum Coil in an Air Conditioner Advantages

The utilization of aluminum coils in air conditioners offers several notable advantages.

- Firstly, aluminum is a lighter metal compared to copper, resulting in reduced weight and improved portability of air conditioning units. This lightweight characteristic makes installation and transportation more convenient.

- Secondly, aluminum is highly corrosion-resistant, making it an ideal choice for outdoor units that are exposed to various weather conditions. Unlike copper, aluminum coils are less prone to rust and deterioration, leading to increased durability and longer lifespan of air conditioning systems.

- Additionally, aluminum coils possess excellent heat transfer properties. They enable efficient heat exchange, allowing air conditioners to cool or heat spaces more effectively. This improved thermal conductivity contributes to energy efficiency and lower operating costs.

- Moreover, the use of aluminum coils has a positive environmental impact. Aluminum is a highly recyclable material, and its production requires less energy compared to copper. By incorporating aluminum coils into air conditioning systems, manufacturers can contribute to sustainability efforts and reduce their carbon footprint.

- While there are advantages to using aluminum coils, it is important to note that there is an ongoing debate in the industry regarding the choice of material for coils. Some argue that copper coils still offer certain benefits, such as higher heat transfer rates in specific applications. However, the widespread adoption of aluminum coils in the air conditioning industry demonstrates its effectiveness and cost-efficiency.

Air Conditioners, Aluminum Coil VS Copper Coil

Aluminum Coil

- Pros: Aluminum offers efficient heat transfer at a lower cost than copper. Aluminum is easier to bend than copper, so less aluminum is needed.

- Cons: Aluminum coils are difficult to repair and usually need to be replaced. Aluminum coils are also more difficult to clean and maintain.

Copper Coil

- Pros: Copper coils are stronger, easier to maintain and more reliable than aluminum coils. Copper has a better heat transfer rate and is easier to repair in the field if the coil is damaged.

- Cons: The cost of copper continues to rise and copper coils need more material than aluminum coils. Copper can corrode, although it can be prevented by using a coating.

| Copper coil | Aluminium coil | |

| Cost | Expensive | Economical |

| Heat transfer rate | High | Low |

| Corrosion | Formicary corrosion,can be avoided, by regular cleaning | Galvanic corrosion, Hard to avoid, it’s hard to clean due to covering metal cabinet |

| Durability | Stronger and durable | Less stronger and less durable |

| Can be repairable | Yes, easily | No, in most the case to replace with new coil. |

Summary

| Characteristics | Copper coil | Aluminium coil |

| Heat transfer | Better than aluminium | Lower than copper |

| Corrosion | Can corrode but can be maintained by cleaning regularly and can also be repaired easily. | Aluminium can also corrode and it is difficult to repair in case of corrosion and thus needs replacement. |

| Pliability | More metal needed to make coil | As compared to copper lesser metal is required to make the coil |

| Cost | Raw copper is costlier than aluminium | Raw aluminium is cheaper than copper. |

| Durability | Stronger than aluminium, hence more durable | Not as strong as copper, hence less durable. Often needs to be placed in heavy cabinet for protection. |

| Ease of maintenance | Easier to clean and maintain. | Difficult to clean due to cabinet around it. The micro channels can also get clogged and cleaning the same is difficult. |

| Repairing | Easy to repair on field. | Difficult to repair on field. Many times it may need complete replacement. |