Aluminum foil finds wide-ranging applications in the energy industry:

Aluminum Foil in Energy Industry

Aluminum foil can enhance energy conversion efficiency, protect equipment from interference, and provide electrical insulation, among other functionalities.

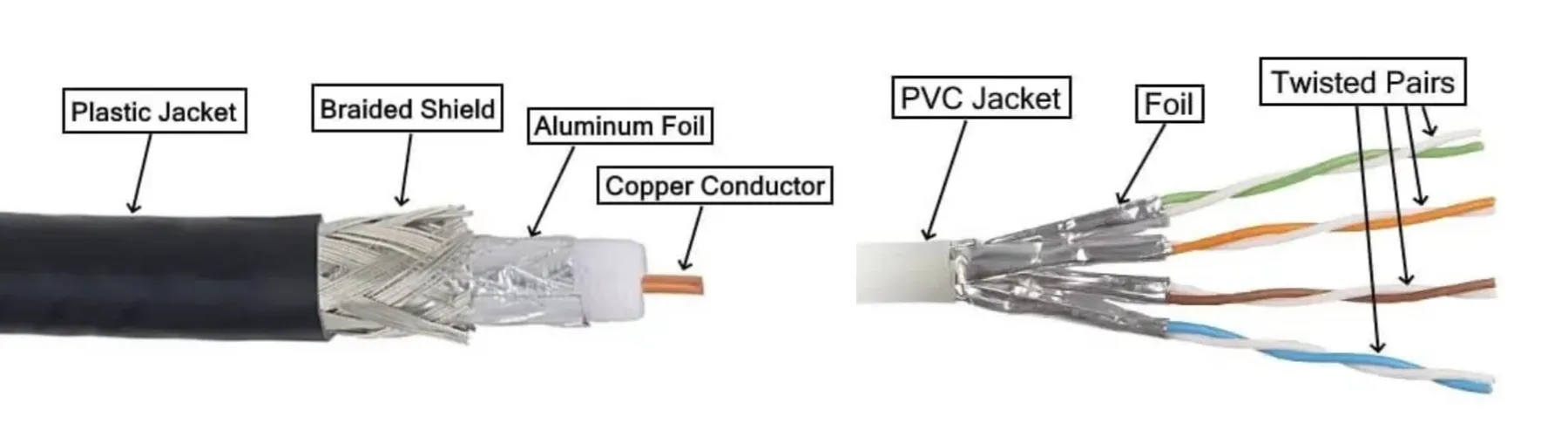

Cables and Transmission Lines: Aluminum foil is commonly used as an insulating layer in cables and transmission lines. Cables typically consist of conductors, insulation layers, and protective coatings. Aluminum foil serves as part of the insulation layer, providing insulation to the cable and preventing current leakage and external interference. With its excellent conductivity and corrosion resistance, aluminum foil is an ideal choice for cable insulation. In high-voltage transmission lines, aluminum foil is also used as a shielding layer to reduce electromagnetic interference and losses.

Solar Concentrators: Aluminum foil is used in solar concentrators. Solar concentrators utilize mirrors or reflectors to focus sunlight onto solar cells, increasing the absorption and conversion efficiency of solar energy. Aluminum foil acts as a reflective layer, helping to enhance the efficiency of solar concentrators.

Batteries: Aluminum foil plays a crucial role in battery manufacturing. Firstly, it is used in the production of aluminum electrolytic capacitors, which are commonly used in power electronics applications and circuit boards. Aluminum foil serves as the electrode in capacitors, providing a large surface area and excellent electrical conductivity.

Secondly, aluminum foil is widely employed in lithium-ion batteries. Lithium-ion batteries are commonly used as energy storage solutions in many portable electronic devices and electric vehicles. Aluminum foil is utilized as current collectors and separators in lithium-ion batteries, allowing for the collection and transfer of electrical current from the positive and negative electrodes.

In addition to its role in aluminum electrolytic capacitors and lithium-ion batteries, there are carbon-coated aluminum foil that are also important in battery manufacturing. These foils are used as anode current collectors in lithium-ion batteries, providing a conductive and stable platform for the deposition of active electrode materials. The carbon coating on the aluminum foil enhances its conductivity and improves the adhesion of the active material, resulting in better battery performance and longevity. The combination of aluminum foil and carbon coating contributes to the overall efficiency and reliability of the battery system.

Transformers: Aluminum foil is used as an insulating material in transformers. Transformers are critical devices in power systems, used to change voltage levels. Aluminum foil can be used as an insulating layer in transformers, providing electrical insulation and isolation. It effectively separates different coils and windings, preventing the mixing of currents and mutual interference.

Yongsheng Aluminum Foil

Yongsheng is a renowned supplier with years of experience in the energy industry. We specialize in providing aluminum foil base materials to meet the specific requirements of the energy sector.

Whether it’s for cables transmission lines, solar concentrators, aluminum electrolytic capacitors, lithium-ion batteries, or transformers, our products possess the necessary characteristics and advantages for the energy industry.

We are committed to delivering high-quality products and professional services~

Yongsheng - Providing Ideal Aluminum Foil Base Material for the Energy Industry

| Series | 1000 Series | 3000 Series | 5000 Series | 8000 Series |

| Alloy | 1050, 1060, 1070, 1100, 1235 | 3003, 3004 | 5052 | 8006, 8011, 8021, 8079 |

| Temper | F, O, H14, H16, H18, H19, H22, H24, H26, H28, T4, T5, T6, T651, T652, T112, T351 etc. | |||

| Thickness | 0.001 mm- 0.2mm | |||

| Width | 10mm-2600mm | |||

| Length | Customization | |||

| Quality Control | Consistent thickness and width, tolerance within standards | |||

Excellent Conductivity:

Yongsheng’s aluminum foil base materials exhibit outstanding conductivity, ensuring efficient current transmission. This is crucial for power transmission and storage in the energy industry. Our aluminum foil base materials have low electrical resistance, reducing current losses and improving the efficiency of energy systems.

Exceptional Corrosion Resistance:

Our aluminum foil base materials are carefully designed to possess excellent corrosion resistance. Many applications in the energy industry involve exposure to humidity, chemicals, or other corrosive substances. Our products effectively protect the surface from corrosion and oxidation, ensuring long-term reliability and performance stability.

Superior Mechanical Strength:

Our aluminum foil base materials have sufficient mechanical strength to meet the requirements of energy equipment and technologies. Whether it’s for cables transmission lines or solar concentrators, our products can withstand external stresses and loads, maintaining their shape and integrity to ensure reliable operation of energy equipment.

High Purity and Impurity Control:

Yongsheng’s aluminum foil base materials boast high purity and low impurity content. This is crucial for ensuring stability and reliability in the energy industry. The high-purity aluminum foil provides better electrical conductivity and chemical stability, reducing unnecessary reactions and contamination. We strictly control impurity content to ensure product consistency and reliability.

Lightweight Properties:

Our aluminum foil base materials are lightweight, contributing to the reduction of weight in energy equipment and improving overall system efficiency. Compared to other metal materials, aluminum foil has a lower density, allowing for lighter energy equipment, increased operational efficiency, and reduced energy consumption.

Excellent Processability:

Our aluminum foil base materials have excellent processability, catering to the manufacturing and installation needs of energy equipment and technologies. Whether it’s for cables transmission lines or solar concentrators, our products can be easily cut, bent, formed, and joined. This flexibility allows for the production of customized energy equipment.