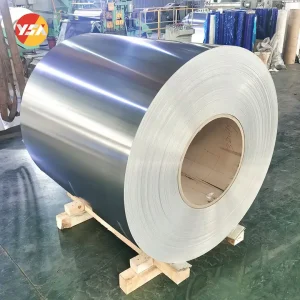

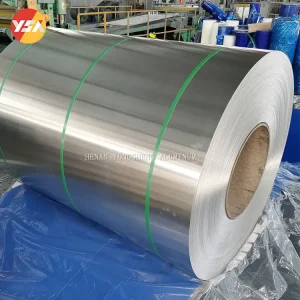

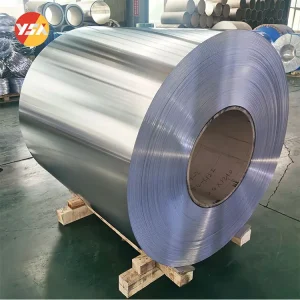

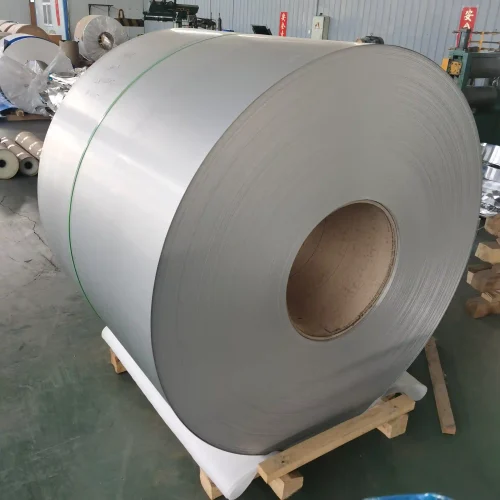

aluminum coil

Directory Navigation

What is Aluminum Coil?

The rolled product that has not been handled by a leveling flying shear but has been calendered by a finishing mill is known as aluminum coil. It serves as the raw material for aluminum sheets and strips. Aluminum coil can be cut into strips using slitting equipment and turned into sheets using flattening equipment. Various types of aluminum coils can be distinguished based on alloys, surface treatments, applications and processing.

Aluminum Coils are Classified by Aluminum Alloy Type

1000 Series Aluminum Coil

Common alloys in 1000 series aluminum coil includes 1050 aluminum coil, 1060 aluminum coil, 1100 aluminum coil. The aluminum coil 1000 series belongs to the pure aluminum group, mainly composed of 99% or higher aluminum content. Famous for its fantastic anti-rust characteristics, high electrical conductivity, and good thermal conductivity, the 1000 series aluminum coil is extensively used in many kinds of industries such as electrical, chemical, and architectural uses.

3000 Series Aluminum Coil

Common alloys in 3000 series aluminum coil includes 3003 aluminum coil, 3004 aluminum coil. The 3000 series aluminum coil is an alloy that primarily consists of manganese. It provides a good combination of strength, formability, and anti-rust characteristics, making it fantastic for a range of applications such as roofing, gutters, and general construction where durability and weather resistance are important.

5000 Series Aluminum Coil

Common alloys in 5000 series aluminum coil includes 5005 aluminum coil, 5052 aluminum coil, 5083 aluminum coil, 5754 aluminum coil. The aluminum coil 5000 series is an alloy primarily composed of magnesium. It has fantastic strength and anti-rust characteristics, making it extensively used in applications such as marine environments, transportation, and structural components where high strength and resistance to hard conditions are need.

6000 Series Aluminum Coil

Common alloys in 6000 series aluminum coil includes 6061 aluminum coil, 6063 aluminum coil. The aluminum coil 6000 series is an alloy that includes silicon and magnesium as its primary elements. It provides a good balance of strength, formability, and anti-rust characteristics, making it fantastic for many kinds of uses including construction, automotive parts, and electrical components. The 6000 series aluminum coil can also be easily extruded into complex shapes or profiles.

Common Alloy Coils

Specifications of Aluminum Coils

| Products Name | Aluminium Coil | ||

| Alloy/Grade | 1050, 1060, 1070, 1100, 1200, 2024, 3003, 3104, 3105, 3005, 5052, 5754, 5083, 5251, 6061, 6063, 6082, 7075, 8011, 8079, 8021 | ||

| Temper | F, O, H | MOQ | 1 Ton |

| Thickness | 0.014mm-20mm | Packaging | Wooden Pallet for Strip & Coil |

| Width | 60mm-2650mm | Delivery | 15-25days for production |

| Material | CC & DC route | Price Term | EXW,FOB,CIF,CFR,CNF,etc. |

| Type | Strip, Coil | Origin | China |

| Standard | GB/T, ASTM, EN | Loading Port | Any port of China, Shanghai & Ningbo & Qingdao |

| Surface | Mill Finish, Anodized, Color coated PE Film Available | Delivery Methods | 1. By sea: Any port in China 2. By train: Chongqing(Yiwu) International Railway to Middle Asia-Europe |

Aluminum Coils are Classified by Surface Treatments

Color Coated Aluminum Coil Surface Treatments

Color coated aluminum coil refers to an aluminum coil that has been coated with a layer of paint or a protective coating in various colors and finishes. Painted aluminum coil enhances the aesthetic appeal of the aluminum coil while providing additional protection against corrosion, weathering, and UV radiation.

Anodized Aluminum Coil

Anodized aluminum coil is an aluminum coil that has undergone an electrochemical process called anodizing, which forms a durable and corrosion-resistant oxide layer on the surface of the aluminum. This process enhances the natural properties of aluminum, providing increased resistance to wear, weathering, and fading, while also offering a range of color options.

Embossed Aluminum Coil

Embossed aluminum coil refers to a type of aluminum coil that has been processed with embossed patterns or textures on its surface. This process involves using specialized machinery to create raised or recessed designs, such as stucco, diamond, or other decorative patterns, on the aluminum surface. The embossing enhances the visual appeal and texture of the aluminum coil, adding both aesthetic and functional value. Embossed aluminum coil finds wide application in various industries, including building and construction, automotive, packaging, and decorative purposes, where its unique textured appearance can provide enhanced grip, anti-slip properties, or simply serve as a design element.

Mirror Aluminum Coil

Mirror aluminum coil is an aluminum coil with a highly reflective, mirror-like surface finish. It is achieved through a polishing and anodizing process that gives the aluminum coil a smooth and reflective appearance, making it suitable for decorative and architectural purposes where a reflective surface is desired.

Diamond Aluminum Coil

Diamond aluminum coil refers to an aluminum coil that has a diamond pattern embossed or stamped onto its surface. This pattern consists of raised diamond-shaped ridges that provide enhanced grip and traction, making it suitable for applications requiring slip resistance and durability.

Aluminum Coils are Classified by Application Scenarios

Aluminum Coil For Construction

Aluminum coil is a versatile material that plays a significant role in construction. Its lightweight nature makes it easy to handle and transport, reducing labor and transportation costs. It offers excellent corrosion resistance, ensuring the longevity and durability of construction components. Aluminum coil can be easily formed, bent, and shaped, allowing for customization and architectural flexibility. Additionally, its recyclability makes it an environmentally friendly choice for sustainable construction practices. Overall, aluminum coil is valued for its advantageous properties and finds applications in roofing, siding, facades, and insulation, enhancing the functionality, aesthetics, and longevity of buildings.

Insulation Aluminum Coil

Aluminum coil for insulation is particularly designed for insulation purposes in many kinds of industries. The choice of alloy for aluminum coil in insulation applications depends on factors such as thermal conductivity, anti-rust characteristics, and specific needs for each insulation project.

Aluminum Coil for Packaging

Aluminum coil for packaging is a type of aluminum coil that is specifically used in the packaging industry. It is widely used for various packaging applications due to its excellent properties, such as lightweight, corrosion resistance, and barrier properties. The choice of alloy for aluminum coil in packaging depends on factors such as strength, formability, and barrier requirements.

Aluminum Coil for Machinery

A particular kind of aluminum coil called “machinery coil” is used especially in the production and building of machinery and equipment. It was selected because to its exceptional mechanical qualities, low weight, and adaptability. A number of criteria, including strength, machinability, and corrosion resistance, influence the alloy selection for aluminum coil used in machinery.

Aluminum Coil for Electronics

Aluminum coil for electronics refers to a type of aluminum coil specifically used in the electronics industry for various applications. It is chosen for its excellent electrical conductivity, thermal conductivity, lightweight nature, and corrosion resistance. The choice of alloy for aluminum coil in electronics depends on factors such as electrical conductivity, thermal management requirements, and formability.

Aluminum Coil for Transportation

The term “aluminum coil for transportation” describes a particular kind of aluminum coil that is used in the rail, automotive, and aerospace industries. It is choiced owing to its high strength, formability, resistance to corrosion, and lightweight nature. The strength, formability, and particular needs of each mode of transportation all have a role in the alloy choice for aluminum coil used in transportation.

Aluminum Coil for Heat Transfer

Aluminum coil for heat transfer refers to a type of aluminum coil specifically designed for applications where efficient heat transfer is needed. It is chosen for its excellent thermal conductivity, lightweight nature, and corrosion resistance. The choice of alloy for aluminum coil in heat transfer depends primarily on thermal conductivity and other factors such as corrosion resistance and formability.

Aluminum Coils in an Air Conditioner

The incorporation of aluminum coils in air conditioning systems has brought about a transformative shift in the industry, offering a multitude of benefits. These coils play a pivotal role in the refrigeration process, facilitating efficient heat transfer and significantly enhancing the performance of air conditioners. One of the major advantages of aluminum coils is their lightweight composition, which simplifies installation and transportation processes. Additionally, aluminum exhibits exceptional resistance to corrosion, ensuring the longevity and durability of the coils, especially in outdoor units exposed to various weather conditions. Furthermore, aluminum boasts excellent thermal conductivity, enabling efficient heat exchange and optimizing the cooling and heating capabilities of air conditioners. Moreover, the utilization of aluminum coils aligns with environmental sustainability efforts, as aluminum is highly recyclable and requires less energy to produce compared to other metals. Overall, the integration of aluminum coils in air conditioning systems has revolutionized their efficiency, reliability, and overall performance, ushering in a new era of advanced cooling technology.

Aluminum Coils are Classified by Processing

Cold rolled and hot rolled are two distinct manufacturing methods used to create aluminum sheets or coils, each imparting unique properties and characteristics to the final product.

CC Process (Cold Rolled)

In the CC process, molten aluminum is directly cast into continuous aluminum ingots. These ingots are then subjected to heating and rolling processes to produce aluminum coils. Aluminum coils produced by the CC process have a uniform microstructure and higher purity, making them suitable for applications with high material performance requirements.

DC Process (Hot Rolled)

In the DC process, molten aluminum is first cast into thick plates, which are then hot-rolled and cold-rolled to the desired thickness to produce aluminum coils. The DC process offers higher production efficiency compared to the CC process, making it suitable for large-scale aluminum coil production.

How to Store Aluminum Coils Correctly?

Maintain Sealed Packaging: Ensure that the outer packaging of the aluminum coil is tightly sealed to prevent exposure to rain or moisture during transportation and storage. This will help avoid material oxidation.

Provide Dry and Ventilated Environment: Store the aluminum coils in a dry and well-ventilated space to prevent them from being exposed to humidity and pollutants. Additionally, ensure that the protective film on the outer layer of the aluminum coil remains intact, safeguarding it against cuts, rubbing from external objects, and impacts.

Avoid Unnecessary Unpacking: Avoid opening the packaging of the aluminum coil until it is required for formal construction or use. Repeated unpacking can lead to the surface of the coil coming into contact with oxygen, resulting in oxidation marks. This can have a negative impact on the subsequent use of the coil and reduce its overall lifespan.

Aluminum Coil Suppliers

Henan Yongsheng Aluminum produces high quality aluminum coil for various applications. Yongsheng is an aluminum sheet/coil/foil/strip factory with 25 years of experience. Our factory focuses on the production and development of aluminum products such as aluminum sheet/coil, aluminum foil, aluminum strip, color-coated aluminum sheet/coil, aluminum circle, embossed aluminum, aluminum checker plate, mirror aluminum plate, anti-skid aluminum plate and so on. Our factory has 27 casting production lines, 2 color-coated aluminum coil production lines, 3 slitting production lines, 4 shearing production lines, 32 punching machines, 10 CNC lathes, 4 embossed aluminum production lines, with an annual output of 300,000 tons above, the export volume accounts for more than 40%. Welcome to visit our factory!

FAQ

Why is aluminum coil preferred to the copper coil?

For many kinds of reasons, copper coil is rarely chosen over aluminum coil. First of all, aluminum is substantially lighter than copper, which reduces transportation costs and promotes handling during installation. What’s more, aluminum has fantastic heat transfer qualities to copper, which improves HVAC systems’ energy efficiency. Copper is more prone to corrosion, but aluminum is likewise very resistant to it, especially in humid and coastal conditions. Lastly, aluminum is a more economical material than copper, which makes it a advisable choice for various uses.

Why is aluminum used for baking?

Because aluminum has good heat conductivity, it is used in baking. It makes sure thorough and consistent baking by distributing heat equally across the baking surface. The rapid and effective heat transfer of aluminum promotes quicker cooking times.

What is the difference between aluminum sheet and coil?

The primary distinction between aluminum sheet and coil lies in their physical form. Aluminum sheet refers to a flat and thin aluminum piece that finds utility in diverse sectors, including construction, automotive, and industrial applications. It is obtainable in varying thicknesses and can be conveniently cut and shaped to meet specific needs. Conversely, aluminum coil is an elongated, continuous roll of aluminum primarily utilized in situations that require a continuous length or shape, such as roofing, insulation, and packaging. Aluminum coil often undergoes additional processing, including slitting into narrower widths or receiving protective coatings.

What is the difference between aluminium foil and coil?

While both aluminum foil and aluminum coil are made of the same metal, they serve distinct purposes and possess unique properties. Aluminum foil is a thin and flexible sheet of aluminum primarily employed in cooking and food packaging. It acts as an excellent barrier, protecting food from moisture, light, and microorganisms. Typically, aluminum foil measures less than 0.2 mm in thickness and can be easily shaped or folded as required. In contrast, aluminum coil is a continuous and thicker roll of aluminum, commonly used in industrial, transportation, and construction applications. It finds use in roofing, insulation, and manufacturing processes, and is available in various widths and thicknesses.

How are aluminum coils made?

Aluminum coils are made through a series of processes. First of all, pure aluminum ingots are melted in a furnace. The molten aluminum is then cast into large cylindrical shapes called billets. The billets are homogenized to make sure uniform properties throughout the metal. Next, the billets are hot-rolled into thin sheets, which are then cold-rolled to achieve the desired thickness and surface finish. The cold-rolled sheets are then coiled into large rolls, creating aluminum coils. These coils can experience further processing, such as slitting or coating, depending on the intended application. The manufacturing process for aluminum coils involves precise control of temperature, pressure, and rolling speed to make sure the desired characteristics and dimensions are achieved.