Aluminum Sheet Supplier China

Aluminum Sheet Supplier China

China is the world’s largest aluminum producer, and representative enterprises in the aluminum processing industry chain are located in Henan, Jiangsu, Shandong and other regions. Henan has an advantageous geographical location and rich bauxite and coal resources. As a global aluminum plate supplier, Henan Yongsheng Aluminum is located in the industrial cluster of Gongyi City, Henan Province. It has 25 years of experience in aluminum processing and manufacturing. The factory covers an area of 193 acres, has 3,200 workers, and has an annual output of 300,000 tons. It is committed to serving global customers. Provide high quality, low price products and excellent services.

Navigation:

- Advantages of Purchasing Aluminum Sheets from Us

- Yongsheng Aluminum Sheet Details

- Yongsheng’s Hot-Selling Aluminum Sheet Plate Products

- Aluminum Sheet Size

- Aluminum Sheet Properties

- Aluminum Sheet Processing Methods

- YSA Aluminum Sheet Application Industries

Building Industry

Electrical Industry

Packaging Industry

Chemical Industry

Transportation Industry - Yongsheng Service

Advantages of Purchasing Aluminum Sheets from Us:

Advantage 1: High Quality

All our products are manufactured using advanced equipment and strict quality control procedures. Export products strictly comply with relevant domestic and international standards such as GB/T 1196-2017, GB/T 3190-2018 to ensure that each product is in the production process There won’t be any problems.

Advantage 2: Factory Price

As an aluminum sheet manufacturer with 23 years of export experience, we always provide you with the most favorable quotation based on international aluminum ingot price + production process + aluminum alloy + other costs, and provide free samples according to your requirements.

Advantage 3: Deliver Timely

Aluminum sheet supplier China ensures timely delivery after you place an order, ensuring that your project can proceed normally, product delivery will never be delayed, and customer reviews can show you the actual situation.

Advantage 4: Perfect After-Sales Service

China’s aluminum sheet supplier – Yongsheng has a professional team to provide you with various consulting services before sales; continue to keep in touch with you during sales, update logistics details in a timely manner to ensure delivery of the goods; continue to provide you with project support after sales All help is available 24 hours a day.

Grade | 1000 Series: 1050 1060 1070 1100 1200 3000 Series: 3003 3004 3005 3103 3104 3105 5000 Series: 5005 5052 5083 5182 5454 5754 6000 Series: 6005 6061 6063 6082 6101 |

Thickness | 0.10mm-350mm |

Width | 100mm-2600mm |

Length | Any |

Temper | O, H12, H14, H16, H111, H22, H24, H26, H28, T4, T6, etc |

Surface Treatment | Mill Finish, Coated, Powder Coated, Anodized, Mirror, Embossed, Checkered, etc. |

Quality Control | Mill Test Certification Is Supplied With Shipment, Third Part Inspection Is Acceptable. |

Yongsheng’s Hot-Selling Aluminum Sheet Plate Products:

1050 Aluminum Sheet

1100 Aluminum Sheet

3003 Aluminum Sheet

5005 Aluminum Sheet

5052 Aluminum Sheet

5083 Aluminum Sheet

5086 Aluminum Sheet

6061 Aluminum Sheet Plate

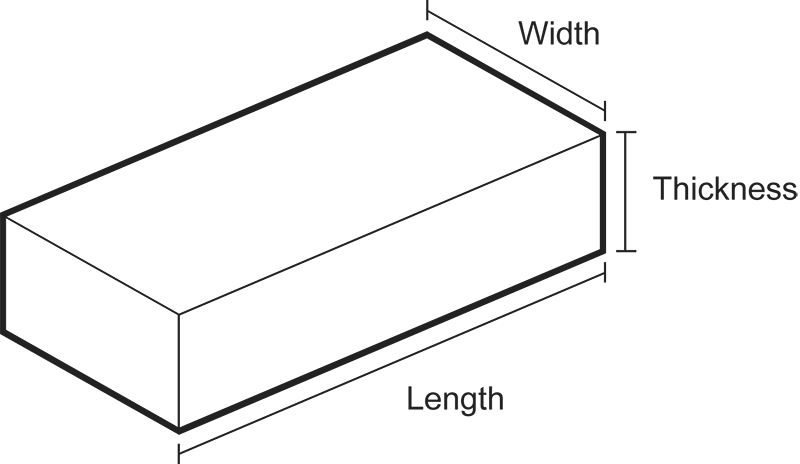

Aluminum Sheet Size:

Aluminum sheet thickness is generally expressed in inches and millimeters, and gauge is sometimes used. According to the thickness of aluminum plate, it can be divided into:

- Thin sheet: 0.15mm-2.0mm

- Plain sheet: 2.0mm-6.0mm

- Medium thickness plate: 6.0mm-25.00mm

- Thick plate: 25mm-200mm

- Extra thick plate: ≥200mm

01. Inch Type

- 1/4 aluminum sheet

- 125 aluminum sheet

- 1/8 inch aluminum sheet

- 1 16″ alumininum sheet

- 3/16 aluminum plate

- .060 aluminum sheet

02. Millimeter Type

- 1mm aluminium sheet

- 1.5mm aluminum sheeting

- 2mm aluminum sheet

- 3mm aluminum sheet

- 5mm inch aluminum sheet

- 8mm alumininum sheet

03. Gauge Type

- 8 gauge aluminum sheet

- 11 gauge aluminum sheet

- 12 gauge aluminum sheet

- 13ga alumininum sheet

- 16gauge aluminum plate

- Gauge 18 aluminum sheet

Some Common Sizes

Aluminum Alloy Temper Introduction:

Aluminum alloys are processed in different ways according to different use requirements. The main processing methods include hot working, cold working, solid solution heat treatment, aging treatment, annealing treatment, etc. The tempers of aluminum processing products can be summarized according to different processing methods:

Temper | Name | Introduction |

O | Annealing temper | Suitable for fully annealed products with minimum strength |

H | Work hardened temper | Suitable for products whose strength is increased by hardening and may also undergo additional heat treatment to reduce strength after work hardening. |

T | Heat treatment temper | It is suitable for products that have been stabilized through (or not through) work hardening after heat treatment. The T code must be followed by one or more Arabic numerals (usually for heat-treated reinforced materials). |

W | Solution heat treatment temper | An unstable state that is only applicable to alloys that have been naturally aged at room temperature after solid solution heat treatment. This state represents The number only indicates that the product is in the natural aging stage. |

F | Free processing temper | It is suitable for products that have no special requirements for work hardening and heat treatment conditions during the molding process. This temper produces The mechanical properties of the product are not specified. |

H temper subdivision

Temper | Details |

H12 | Work hardened to 25% hardness. |

H14 | Work hardened to 50% hardness. |

H16 | Work hardened to 75% hardness. |

H18 | Work hardened to 100% hardness. |

H19 | Super work hardened temper. The tensile strength of this material should be more than 10N/mm2 higher than that of H18 temper material. |

H22 | Partially annealed to 25% hardness after work hardening. |

H24 | Partially annealed to 50% hardness after work hardening. |

H26 | Partially annealed to 75% hardness after work hardening. |

H28 | Partially annealed to 100% hardness after work hardening. |

H32 | After work hardening, stabilize to 25% hardness. |

H34 | After work hardening, stabilize to 50% hardness. |

H36 | After work hardening, stabilize to 75% hardness. |

H38 | After work hardening, stabilize to 100% hardness. |

H42 | Painted after work hardening, 25% hardness treatment. |

H44 | Painted after work hardening, 50% hardness treatment. |

H46 | Painted after work hardening, 75% hardness treatment. |

H48 | Painted after work hardening, 100% hardness treatment. |

H111 | It is suitable for products that have undergone a moderate amount of work hardening after final annealing, but the degree of work hardening is not as good as H11. |

H112 | It is suitable for products formed by hot processing. The mechanical properties of products in this temper have specified requirements. |

H116 | Applicable to products made of 5XXX series aluminum alloys with magnesium content ≥4.0%. These products have specified mechanical properties and spalling corrosion resistance performance requirements. |

T temper subdivision

Temper | Details |

T0 | After solid solution heat treatment, natural aging and then cold working temper, it is suitable for products whose strength is improved by cold working. |

T2 | It is cooled by the high-temperature molding process and naturally aged to a basically stable temper after cold working. It is suitable for products that are cooled by the high-temperature molding process and then cold-worked or straightened to improve strength. |

T4 | Natural aging after solid solution heat treatment to a basically stable temper is suitable for products that will no longer undergo cold processing after solid solution heat treatment (straightening and leveling can be performed, but the mechanical performance limit will not be affected). |

T6 | Natural aging after solid solution heat treatment to a basically stable state is suitable for products that will no longer undergo cold processing after solid solution heat treatment (straightening and leveling can be performed, but the mechanical performance limit will not be affected). |

T8 | The state of cold working after solution heat treatment and then artificial aging is suitable for products that have been cold worked or straightened to improve strength. |

Aluminum Sheet Metal Properties:

Aluminum sheet metal is one of the most widely used abrasive and engineering materials today. This is largely due to some key aluminum sheet metal properties.

Its most valuable features include:

- Lightweight (approximately 1/3 the volume of steel) and therefore a very cost-effective solution in transport and logistics operations.

- Strong enough for a variety of building and structural applications.

- Resistant to corrosion outdoors and in wet environments.

- Easy to form and has a relatively low melting point (660 degrees Celsius), even in thicker gauges.

- Suitable for food grade uses, including direct contact with packaging, as it is non-reactive, completely airtight (even at very light foil thicknesses) and odorless and tasteless.

- Fireproof – Will not burn unless very thin film and does not release toxic gases when melted.

- Highly reflective, suitable for energy-saving heating and lighting systems.

- It has excellent thermal and electrical conductivity (approximately twice that of copper), again making it suitable for economical thermal and power systems.

- Easy to recycle, reducing the loss rate during the decomposition process (currently, about three-quarters of the aluminum plates produced in the past are still in circulation).

- Durable and low maintenance, reducing replacement rates and environmental impact.

- Available in an almost unlimited range of thicknesses and sheet sizes.

Aluminum Sheet Processing Methods:

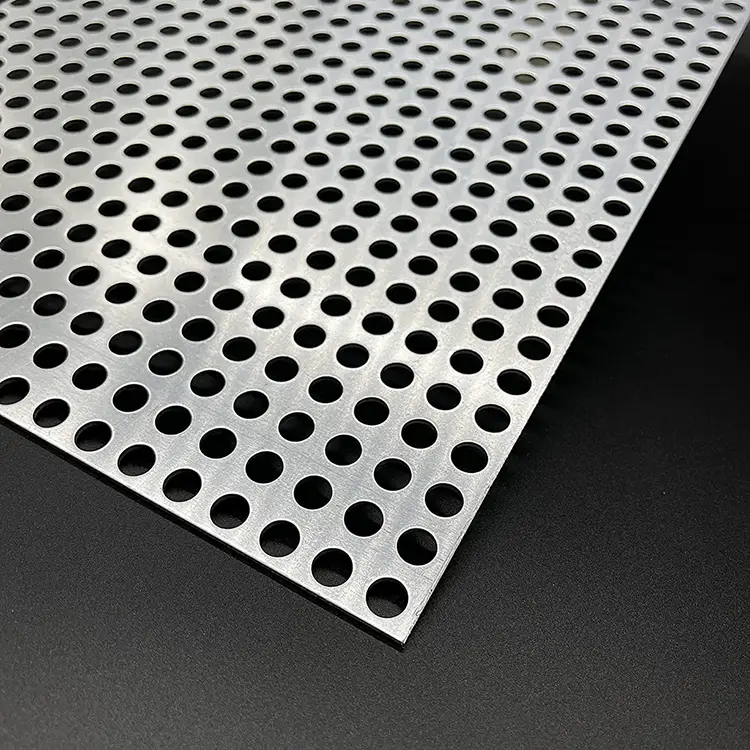

01. Perforated Aluminum Sheet:

Perforated aluminum sheets, also called aluminium perforated metal sheet and aluminium perforated, are made by punching aluminum sheets through punching dies to form metal plate products of various shapes on the surface of the aluminum sheets. Common punching plate hole shapes include: circular, square, groove and decorative patterns.

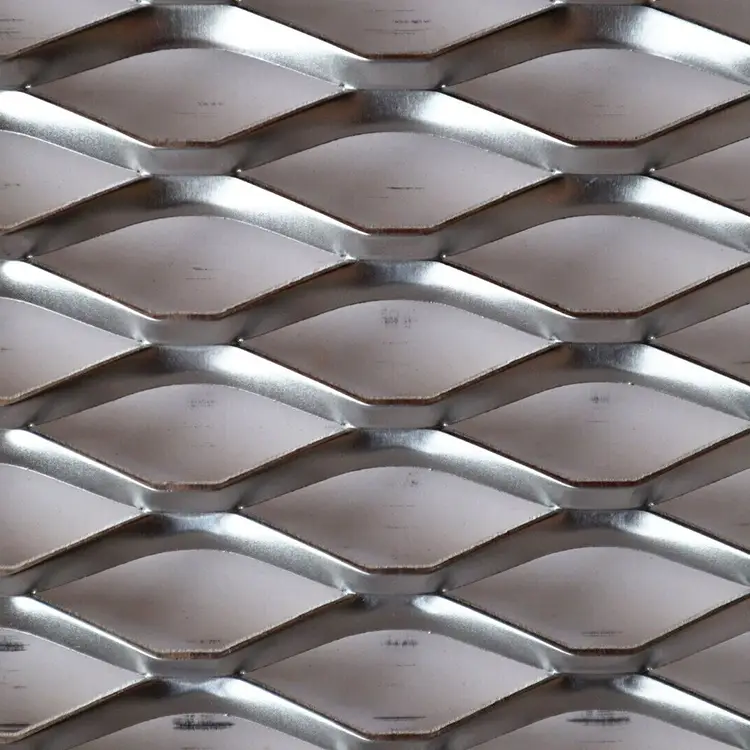

02. Aluminum Mesh Sheet:

Aluminum mesh is also called expanded aluminum mesh. It is a metal mesh with simple patterns such as diamond holes and hexagonal holes that is stretched from the original aluminium sheet through an aluminum mesh machine. Mainly used for house decoration, handicraft production, house ceilings, etc. Aluminum mesh sheets have the characteristics of no rust, beautiful color, durability, excellent quality and high grade.

03. Colored Aluminum Sheet Metal:

Colored aluminum sheet plate is a new type of environmentally friendly coating material that is coated with organic coatings on aluminum sheets and cured at high temperatures. Colored aluminum sheet metal has a flat surface, good weather resistance, and a variety of colors, guaranteed not to fade for 25 years. They are widely used in construction, packaging, air conditioning, refrigerators, solar energy, cosmetics and other industries.

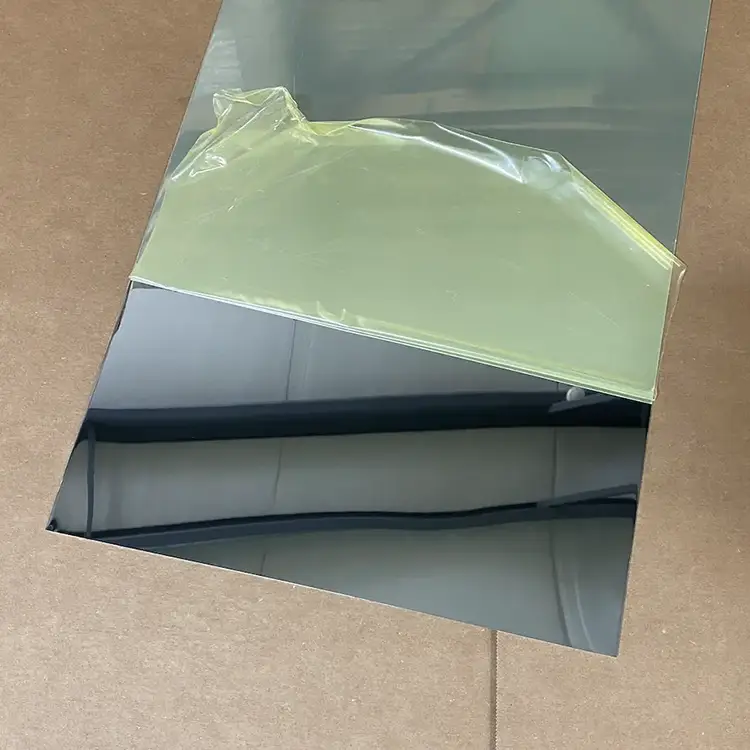

04. Mirror Polished Aluminum Sheet:

Mirror aluminum is a sheet, coil, strip, etc. that is processed through various methods such as continuous rolling and polishing to give the surface of the aluminum sheet a mirror effect. Aluminum mirror sheet has the advantages of light weight, high strength, strong weather resistance, and economical benefits. Aluminum sheet mirror is most commonly used in lighting fixtures, indoor and outdoor architectural decorations, electrical panels, signs, bags, jewelry boxes and other fields.

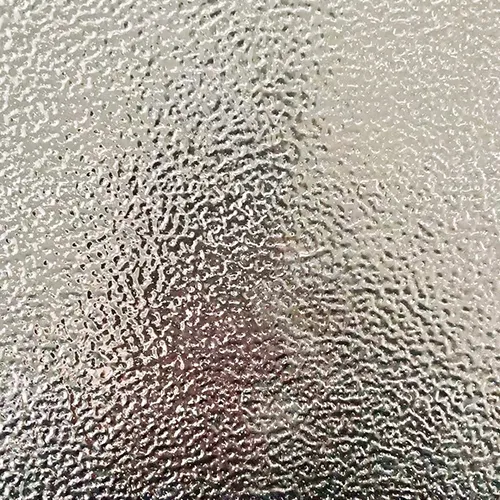

05. Embossed Aluminum Sheet:

The embossed aluminum sheet is pressed on the surface of the aluminum sheet through mechanical rolling. Common embossing types include: orange peel embossed aluminum, ball embossed aluminum, pebble embossed aluminum, etc. The embossed aluminum plate sheet has good decorative effect, strong weather resistance and good corrosion resistance. It is often used in building decoration, such as building exterior walls, ceilings, furniture surfaces, electronic product casings, automobile manufacturing, shipbuilding, etc.

06. Aluminum Tread Plate:

Aluminum tread plate is also called aluminum checker plate, which made by feeding the aluminum alloy metal material into the metal mold through a hydraulic press, roller pressing equipment, etc., and applying high pressure and heat to form it. Common types of aluminum tread plates on the market include: 5 bars aluminum checker plates, 3 bar aluminum checker plates, aluminum diamond plates, pointer aluminum tread plates, etc. Aluminum tread plates have excellent anti-skid properties and are relatively cheap.

07. Anodized Aluminum Sheet:

Anodized aluminum sheet plate is an aluminium sheet placed in the corresponding electrolytic solution as an anode, and electrolysis is performed under specific conditions and applied current to form a thin oxide layer. Anodized aluminum sheets are of higher quality than ordinary aluminum plates, have stronger corrosion resistance, higher fire resistance, and a higher price. Widely used in mechanical parts, precision instruments, smartphones, aircraft and automotive parts, and other fields.

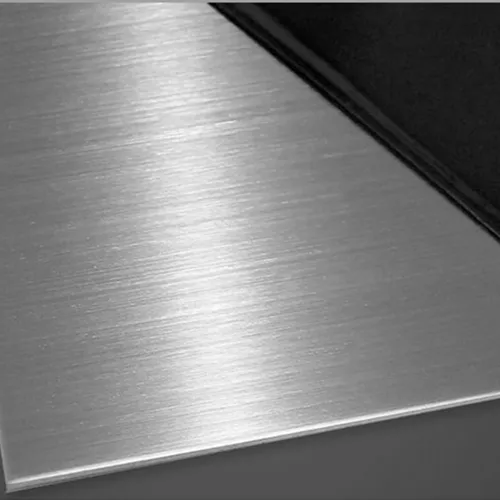

08. Brushed Aluminum Sheets:

Brushed aluminum sheet is a manufacturing process where lines are repeatedly scraped out of aluminum using sandpaper. Brushed aluminum sheets are widely used in aluminum-plastic panels, fireproof panels, aluminum photo frames, boutique cabinets, and other fields. The brushed aluminum plate has the advantages of high aesthetics, long-lasting weather resistance, and excellent processing performance. Its corrosion resistance is 3 times that of ordinary aluminum plates, and it is antistatic, non-dust-absorbing, and scratch-resistant.

YSA Aluminum Sheet Application Industries:

Building Industry:

Aluminum products used in construction include aluminum sheet, aluminum composite sheet and other materials. The most commonly used is aluminum plate because it can be sprayed, has good strength, low cost and long service life. If it is not in direct contact with steel, the aluminum plate can be hung on the wall. , it will not fall off or corrode for 50 years. Aluminum plates sheets are widely used in the construction industry, not only because they can be cut, bent and processed freely, but also because they are lightweight and easy to construct and install. This is one of the main reasons why they are widely used in the construction industry.

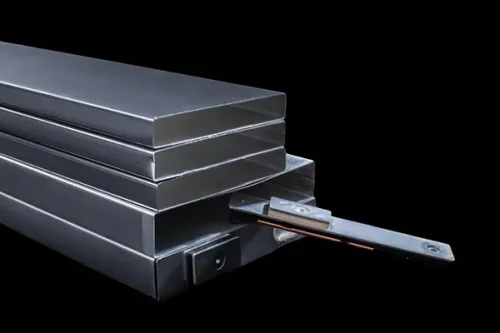

Electrical Industry:

Aluminum alloys are mainly used in consumer electronics products in the form of casings, frames, radiators, etc. Among them, 5000 series aluminum and 6000 series aluminum are the most commonly used aluminum alloy series. Mechanical accessories, car amplifier panels, battery casings, mobile phone casings, motor casings, wire ducts, LED screen frames, lampshades, photography accessories, etc. are all made of aluminum alloy. Commonly used alloy grades are 1060, 3003, 5052, 6011, 6061, 6063 aluminum, etc.

Packaging Industry:

Although aluminum plates are not as widely used in the packaging industry as aluminum foil packaging, aluminum plates are used in the production of food cans due to their thin walls, high compressive strength, not easy to be damaged, and will not react with internal substances during long-term use. Beverage cans, cosmetic packaging, bottle caps, etc. are ahead of other metals. 3003 and 3004 of 3000 series aluminum are alloys commonly used in can making. Its deep-processed products 3003 aluminum strip and 3004 aluminum strip are also popular choices for manufacturing bottle caps. Other aluminum alloys like 1050, 1060, 5052, 8011, 8021, etc. are also common alloys in the packaging field.

Chemical Industry:

Aluminium sheets are commonly used in the chemical equipment industry to manufacture chemical storage tanks, containers, pump bodies and valves. In chemical equipment that requires corrosion resistance and strength, 5052 aluminum sheets, 5083 aluminium sheets, 6061 aluminum sheets, etc. are commonly used for final processing. If you manufacture pipes and pipe connections specifically for the chemical industry, 3003 aluminum alloy and 6061 aluminum alloy are usually used. Aluminum plates are also used in some low-temperature and low-pressure applications. Common alloy grades include 6063 and 5086.

Transportation Industry:

Aluminium sheets are also widely used in the field of transportation, such as automobile manufacturing, railway manufacturing, ship manufacturing, etc. Aluminum plates sheets can effectively reduce the weight of cars, ships, and trains, improve transportation efficiency, and reduce energy consumption and carbon emissions. details as follows:

Automotive System:

In the automotive industry, aluminum plates are mainly used to manufacture body parts and structural parts. The aluminum sheet alloy series for automobiles are mainly 5000 series and 6000 series. Aluminium sheets such as 5052 and 5083 have high strength and corrosion resistance and are often used in body panels and structural parts; 6061 aluminum and 6063 aluminum have good welding properties and are widely used in body structures, chassis, suspension systems, etc.

Alloy | Applications |

5182 | Car doors, car hoods, car front and rear fenders, etc. |

5053, 5754, 5052 | Car underbody protection, car gas tanks and other parts. |

5052, 5083 | Car door. |

6061 | Car wheels. |

5754 | Fuel tank. |

Railway System:

Aluminum plates also have some uses in the railway and transportation fields. 3003 aluminum plates are often used in road traffic to make road signs, traffic signs, etc.; 5052 has good tensile strength and corrosion resistance and is widely used in high-speed rail carriage interiors, body panels, and tracks. Transportation vehicle shells, etc.; 5083 aluminum also plays a significant role in the construction of railway vehicles; 6061 is the most popular application in the body structure, carriage manufacturing, and structural components of high-speed rail and railway vehicles.

Marine System:

Marine grade aluminum sheets are mainly aluminum-magnesium alloys, aluminum-magnesium-silicon alloys and aluminum-zinc-magnesium alloys. The most common marine aluminum plate is 5083 aluminum sheet. It is an aluminum-magnesium alloy with low density, high toughness, high corrosion resistance and weldability. It is mainly used on ship hulls and can well adapt to harsh marine environments. In addition to 5083 aluminum sheets, marine-aluminum sheets also include 5052 aluminum sheets, 5086 aluminum sheets, 5059 aluminum sheets, 6061 aluminum sheets, 6063 aluminum sheets, etc. The application of aluminum alloy can reduce the weight of the ship, improve the speed and the overall performance of the ship.

The aluminum alloy commonly used for windows in ship superstructures is 6063 aluminum alloy, and 6063 and 6061 aluminum are often used for masts and stairs. In addition, the wall panels use extruded aluminum-magnesium alloy, which can prevent deformation during welding and ensure a more reasonable stress distribution. The application rate of aluminum-magnesium alloys in ship hull structures is relatively high, among which 5454 and 5052 aluminum alloys are the main materials for manufacturing decks.

Yongsheng Service:

1. ISO, RoHS verified outstanding manufacturer.

2. The third party inspection: SGS, BV, CE, COC, AI and other

3. Standards:ASTM-B209,EN573-1,GB/T3880.1-2006.

4. Flexible Payment :T/T,L/C,D/A,D/P,West Union, Money Gram, etc.

5. Sufficient stock.

6. Quick delivery time.

7. Tracking picture of transport : production, loading and reinforcement loading pictures.

8. Rich experience professional sale team.